Stretch Film

Back to Load Securement and Protection

Custom Engineered Stretch Film Solutions to Optimize Your Supply Chain

Lightweight, cost-effective stretch wrap film designed for low-volume operations, unstable pallets or facilities without automated systems. Available in blown or cast film types

High-performance stretch wrap engineered for consistency, efficiency and speed in automated or semi-automated pallet wrapping systems.

What Makes Millwood Stretch Film Different?

For decades, customers have trusted Millwood to protect what matters most — their products and their reputation. That same expertise that built our leadership in pallets now powers our stretch film solutions. Every roll is backed by engineering precision, proven performance and a nationwide network designed to keep your supply chain moving with confidence.

At Millwood, stretch film isn’t just another packaging material — it’s an integral part of how we help customers reduce waste, improve efficiency and secure every shipment from warehouse to delivery. Through in-house validation, advanced containment testing and decades of load optimization experience, we ensure every stretch film performs under real-world conditions. Our goal is simple: stable loads, reduced damage and peace of mind at scale.

Key Advantages of Millwood Stretch Film:

-

Validated Performance: Each film type is tested and certified in our ISTA lab to guarantee containment strength and consistency.

-

Engineered Versatility: Available in both hand and machine films, optimized for your volume, automation and load type.

-

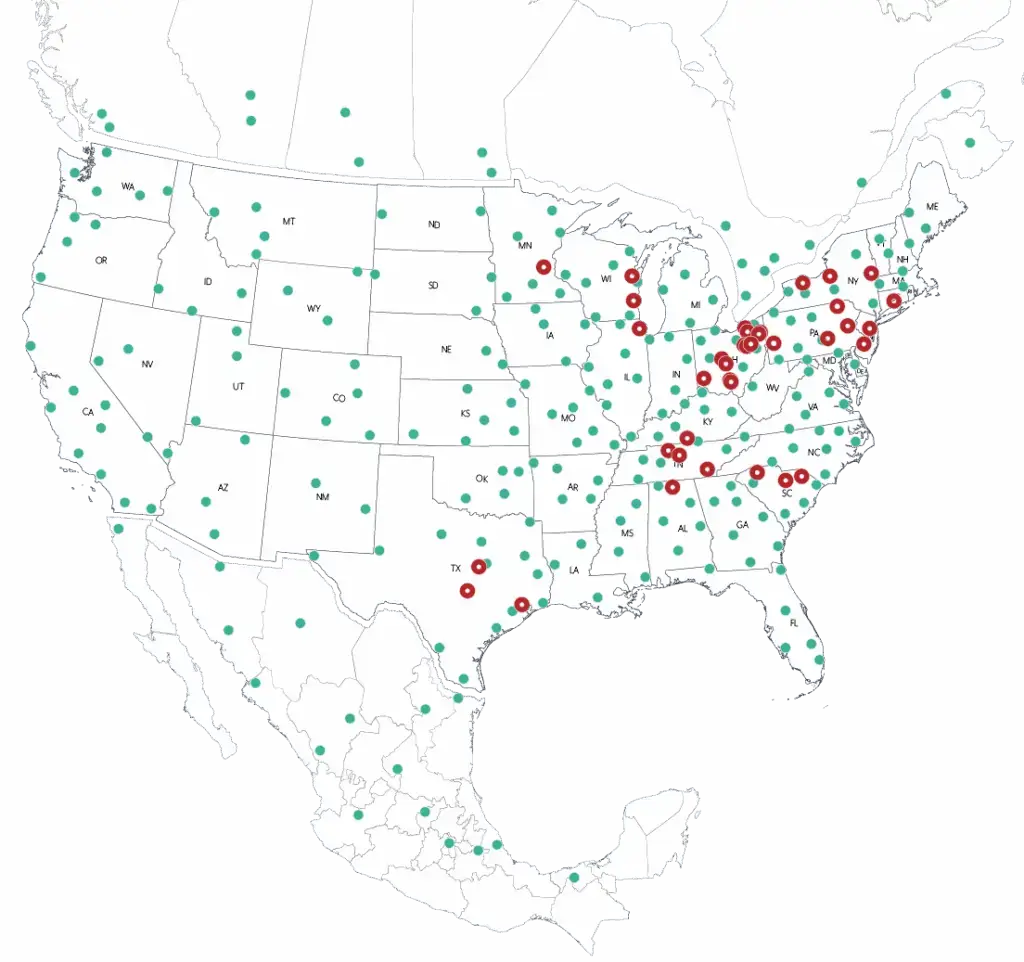

Nationwide Reliability: Supported by 37+ manufacturing and recycling facilities with 250+ partners for consistent availability.

-

Sustainable Protection: Designed under our Perfect Stewardship model to reduce film waste and support greener operations.

-

Partnership-Driven Innovation: Developed collaboratively with our customers to address evolving packaging demands.

When you partner with Millwood, you gain more than a product — you gain a proven ally dedicated to securing your goods, your workflow and your long-term success.

3 WAYS MILLWOOD MAKES BUYING STRETCH FILM EASY

We Listen & Understand

We take time to learn your operation—volume, equipment, pallet types and shipping conditions—so we can recommend the best film type, thickness, and application.

We Test First & Build Right

Every stretch film solution is validated in our ISTA-certified lab to replicate real-world handling, strapping and shipping. This ensures optimized performance before rollout, reducing rewraps, claims and cost. Hand Stretch Wrap | Cast & Blow…

We Deliver Consistently

With a nationwide manufacturing and distribution network, Millwood ensures consistent film supply, shorter lead times and the peace of mind that comes with reliable service.

Leveraging Our Experience to Serve You

We understand that customers choosing stretch film want more than just wrap—they want a partner who can deliver consistent quality, reliable availability and competitive pricing across all packaging materials. Millwood brings the same experience and dependability that made us a leader in pallets to our full range of load securement solutions, including stretch wrap.

Source and Supply

With 37 strategically located manufacturing and repair facilities, 250+ strategic partners across North America and 1.5 million square feet of manufacturing and distribution space, Millwood controls its supply chain from the forest to the finished product. We handle more than 200,000,000 pallets and process over 100,000,000 board feet of lumber per year. Our vertically integrated operations ensure quality and reliable supply for our customers.

Exceptional Service

Serving others is our highest aim. Our dedicated customer support team delivers personal attention, not automated replies, with the care, integrity and expertise you deserve. We prioritize people by listening to your questions and concerns to provide the best support. When you connect with Millwood, you can expect an experience marked by professional care and genuine responsiveness. Trust us for consistent, customer-focused service that truly exceeds your expectations.

Sustainable

Operating under a culture of Perfect Stewardship, Millwood is committed to efficiency without compromise to our environment. From the way that our trees are harvested to our innovative line of sustainable packaging products and numerous recycling programs, we will work with you to reduce waste and meet your sustainability goals. Partner with us for sustainable solutions that support your business while protecting our planet.

Providing Comprehensive Stretch Film Solutions That Scale as Your Business Grows

LET’S BUILD TOGETHER

Building strategically with Millwood means having a partner who can grow with you—no matter your size or goals. Whether you’re operating two locations or two hundred, choosing Millwood is a smart move because we are built for scale. We serve some of the nation’s largest brands and know how to support growth at every stage, from startups expanding rapidly to industry leaders adding facilities nationwide. That scalability ensures your packaging and pallet supply stays reliable and efficient as your business evolves.

We make scaling simple because we understand multi-location needs and service them with one integrated solution. Our nationwide reach and proven processes mean you don’t have to manage different suppliers for each region—we take care of it all. When time is critical and your business is growing fast, our ability to deliver consistently, at scale, across multiple facilities makes us a strategic partner you can count on.

Millwood is more than a pallet supplier—we’re a one-stop packaging solutions partner. From pallets to load securement, recycling solutions, and strategic sourcing, we help optimize your supply chain and support your sustainability goals. Whether you buy 500 pallets a month or 5 million, we have the infrastructure, expertise, and flexibility to scale with you. Partnering with Millwood means you gain a reliable ally who helps you focus on your growth while we handle your packaging needs. We would look forward to talking with you to see how we can help serve you.

As part of our Load Securement & Protection product line, Millwood’s Corner Protectors are designed to protect products from dents, strapping abrasions and shipping and handling damage.

Millwood Lab

Our ISTA-certified lab replicates real-world shipping conditions to test and validate stretch film performance. By optimizing containment and load stability, we help you reduce product loss and minimize rewrap costs.

PalletView

Track the quantity and condition of various managed assets such as pallets, tier sheets, plastic dunnage and airbags with PalletView, our proprietary web-based application.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

See How We've Helped Others

When a national packaging provider faced rising freight costs, safety risks and product damage from inconsistent crate construction, they needed a scalable solution. Working together, we and our partner engineered an integrated packaging system that combined corner protection with custom crate design to strengthen performance and eliminate inefficiencies.

Through collaboration, testing and process control, we delivered consistent quality, improved safety and reduced total cost per unit — proving that partnership drives stronger results than competition ever could.

- Reduced total cost per unit by 10% through optimized crate design and stacking efficiency

- Shipped 3.4 million linear feet of product annually with zero safety incidents since launch

- Delivered consistent, high-quality protection through a unified engineering and supply approach

Reliable. Available. Local.

We understand it is important to know that your pallets will be delivered on time, every time. That's why we are where you are.

Frequently Asked Questions

Stretch film is a plastic film applied around palletized loads to secure and stabilize them during shipping and storage. It helps prevent shifting, tipping and damage while improving handling and protection from dust or moisture.

Stretch film works by applying consistent tension that holds items tightly together, forming a secure unit load. This ensures products remain stable throughout transport and storage. Available in both hand and machine varieties, it allows businesses to match performance with operational needs. Millwood’s stretch film solutions are validated through ISTA-certified testing to deliver consistent containment, reduce product damage and improve overall supply chain efficiency for customers across various industries.

Hand stretch wrap is applied manually for low-volume or irregular loads, while machine stretch wrap is used in automated systems for higher speed, consistency and reduced material waste.

Hand stretch film is ideal for smaller operations, warehouses without automation or unstable pallets that can’t be machine-wrapped. Machine stretch film is designed for automated or semi-automated wrapping systems, ensuring consistent tension, faster throughput and less operator strain. Choosing between them depends on load volume, equipment and labor resources. Millwood helps customers identify the best fit, providing both options to ensure efficiency, stability and cost-effectiveness across operations of any size or complexity.

Choose blown film for heavy, sharp or irregular loads requiring higher tear resistance; select cast film for clear visibility, quieter unwinding and cost efficiency.

Blown stretch film is manufactured through a blown extrusion process, resulting in higher strength and puncture resistance. It performs best in demanding environments with uneven or heavy loads. Cast stretch film, produced by a flat die process, provides exceptional clarity for barcode visibility and smooth application. It’s ideal for lighter or uniform loads where noise reduction and cost efficiency are priorities. Millwood offers both types to help customers match film performance, clarity and load profile requirements while balancing strength, stretch and sustainability goals.

Yes. Stretch film applies even containment force across the load, reducing shifting and damage in transit while improving safety and efficiency.

Properly applied stretch film ensures that items remain tightly bound, locking them into a single, cohesive unit. This stability minimizes load movement, tipping or collapse during shipping and handling. Machine-applied stretch film further enhances consistency by maintaining uniform tension throughout each wrap cycle, while hand-applied film offers flexibility for irregular loads. Millwood tests all film types under real-world vibration and handling simulations, ensuring performance standards meet or exceed industry requirements — ultimately protecting your products, lowering freight claims and improving overall operational reliability.

Yes. Millwood offers recyclable film options designed to reduce waste and support sustainability initiatives across your packaging process.

Many stretch films are made from recyclable materials and can be reused or processed through approved recycling programs. Millwood’s sustainability approach, guided by our Perfect Stewardship philosophy, emphasizes efficiency without environmental compromise. Our eco-friendly films minimize plastic waste by improving pre-stretch performance and reducing product damage. Combined with our recycling and pallet recovery programs, Millwood helps customers reach environmental goals while maintaining cost efficiency. Choosing the right film not only protects your products but also supports a greener, more sustainable supply chain.

Yes. Millwood provides stretch film across North America through its extensive manufacturing and distribution network.

With more than 37 facilities and over 250 partner locations nationwide, Millwood ensures reliable product availability and short lead times. This scale allows customers to consolidate vendors and maintain consistent packaging quality across multiple sites. Whether you need hand wrap for low-volume operations or machine film for automated systems, our national footprint and integrated supply chain mean you’ll always have dependable access to the products and expertise you need. Millwood delivers performance, reliability and partnership wherever your business operates.