Knockdown Crates

Back to Wooden Crates

Know What You're Looking For?

Need Help Designing Your Create?

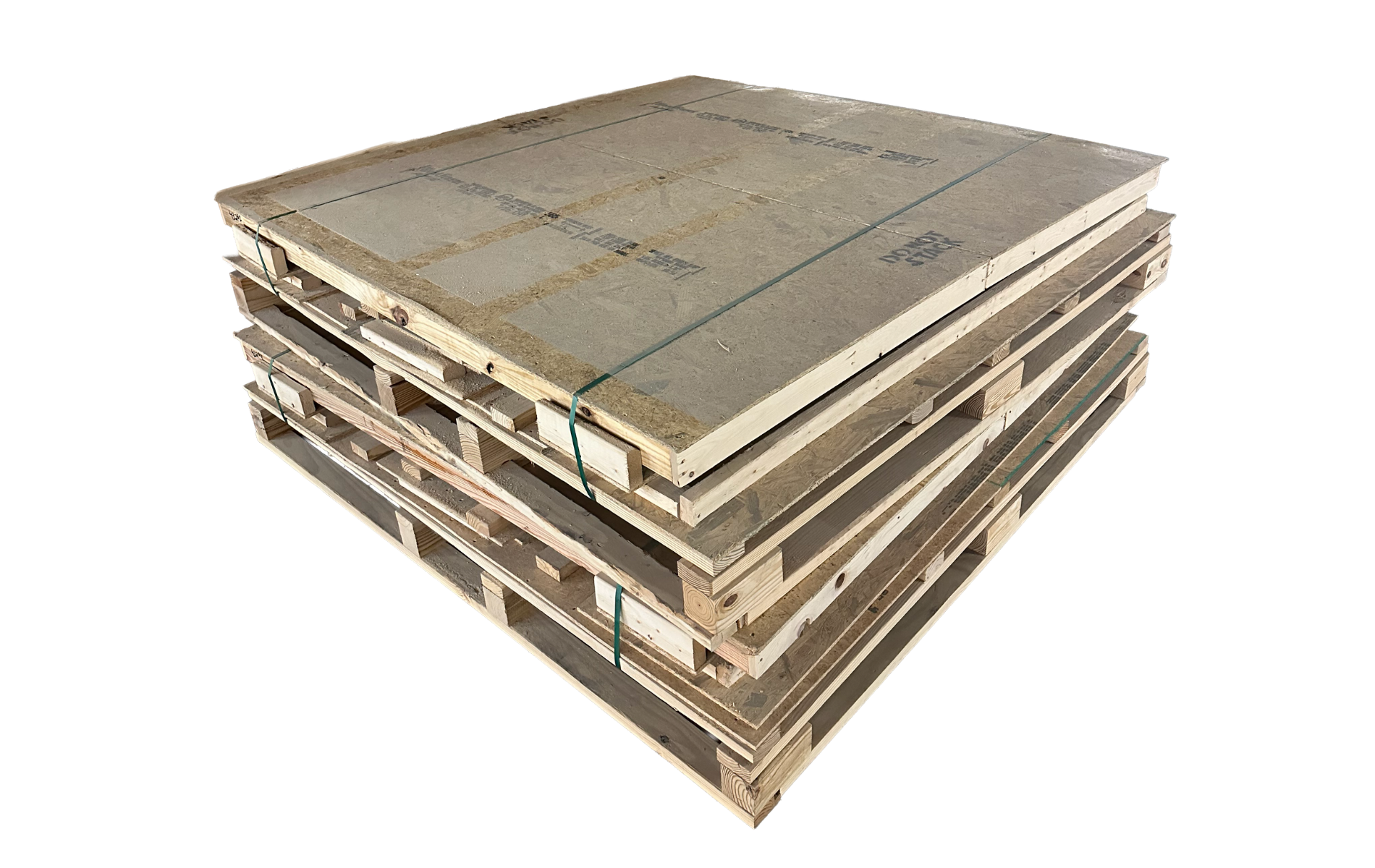

Knockdown Crates for Efficient Safe Shipping

Millwood’s knockdown crates deliver strong, reusable protection with the convenience of tool-free assembly. Using durable steel clips instead of screws or nails, these crates ship flat, save freight costs and safely secure high-value products during transport.

Quick, Tool-Free Assembly

Knockdown shipping crates snap together using spring steel clips, eliminating the need for drills or nail guns. This design reduces labor costs, removes safety concerns and makes setup easy for any team, even in restricted environments.

Reusable and Space-Saving

Engineered for repeated use, knockdown crates prevent material damage caused by fasteners. Panels hold up over multiple trips, while flat-pack shipping maximizes truckload efficiency—cutting freight expenses and simplifying returns for industries across Ohio and nationwide.

Custom Requirements? No Problem

We know that no two applications are the same. That’s why we leverage our ISTA-certified Millwood Lab to engineer custom industrial crating solutions tailored to your exact load and handling requirements. Our approach avoids:

-

Over-engineering that drives up cost

-

Under-engineering that risks damage

-

Instead, we deliver just-right solutions backed by packaging science.

Why Choose Millwood As Your Crating Supplier?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of crating design and supply chain logistics.

-

Innovative Design & Testing: Our in-house ISTA-certified lab and custom design enable tailored, optimized crating solutions.

-

Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Crating Options

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their crating and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify and optimize designs to reduce product damage, minimize waste and improve supply chain efficiency.

Custom Design

Millwood guarantees full 3D modeling and drawings for every RFQ within 24-48 hours. Our design team will review your specifications to ensure that your custom engineered crating solution meets your application requirements, with our operations team ready to rapidly scale production capacity as needed.

Providing Supply Chain solutions

We’ve hand-picked these products to create a comprehensive solution that complements your crating needs.

Certified pallet heat treatment that eliminates pests and ensures compliance with global ISPM-15 regulations. Export-ready, chemical-free and eco-friendly.

Steel, polyester and polypropylene strapping engineered for load containment. Works with tensioners and sealers to secure heavy or high-value goods.

Hand and machine stretch wrap options that contain loads, prevent shifting and protect against dust and moisture with cost-efficient application.

Frequently Asked Questions

What are knockdown clip crates?

Knockdown clip crates are reusable wooden shipping crates that assemble quickly using steel clips instead of nails or screws. They ship flat, save space, reduce freight costs and provide safe protection for heavy or high-value products.

Knockdown crates are designed for both one-way and returnable supply chains. Unlike nailed or screwed crates, the clip system avoids material damage and allows panels to be reused multiple times. These knockdown shipping crates are especially useful for industries handling bulky, delicate or expensive items, such as bathtubs, medical devices or industrial machinery. Companies in Ohio and across the Midwest often choose knockdown shipping crates for efficient freight savings, ease of use and reliable protection during transit.

Why choose knockdown shipping crates over traditional nailed crates?

Knockdown shipping crates assemble faster, eliminate the need for power tools and maintain panel integrity for reuse. They also ship flat, which maximizes truckload efficiency and lowers freight costs compared to traditional nailed crates.

Traditional wood crates often lose strength with repeated use because nails or screws damage panels. Knockdown clip crates use spring steel clips, keeping panels intact and extending service life. The flat-pack design is especially valuable for manufacturers in Ohio and beyond, allowing three times as many crates to fit in a truckload compared to fully assembled designs. Businesses benefit from lower freight costs, easier storage and safer assembly that doesn’t require nail guns or drills at the point of use.

What industries benefit most from knockdown crates?

Industries that ship large, heavy or delicate equipment—such as plumbing, medical, automotive and industrial manufacturing—benefit most from knockdown crates. These industries need secure shipping solutions that can be reused and assembled without tools on the production floor.

Knockdown shipping crates are especially popular with companies like plumbing fixture manufacturers, who often replace corrugated packaging with stronger wood crates. Hospitals and medical suppliers benefit because knockdown crates can be opened and closed without sharp tools, keeping sensitive environments safer. Automotive and industrial manufacturers in Ohio and nationwide also use knockdown shipping crates to transport machinery, components and high-value parts, taking advantage of flat-pack efficiency and reusable design to lower long-term shipping costs.

Are knockdown shipping crates reusable?

Yes. Knockdown shipping crates are engineered for repeat use, with clip connections that preserve panel quality. Unlike nailed crates that degrade after multiple assemblies, clip crates maintain integrity and reduce total packaging costs over multiple shipments.

The reusability of knockdown crates makes them a sustainable, cost-saving choice. By avoiding nail holes or stripped screws, the wooden panels last longer and can endure repeated shipping cycles. Many Ohio-based manufacturers and distributors choose knockdown shipping crates specifically for returnable supply chains, where crates are sent out, unloaded and then flat-packed for return. This design reduces waste, lowers per-trip crate costs and makes supply chains more environmentally responsible while protecting high-value goods.

How do knockdown shipping crates save on freight costs?

Knockdown crates save on freight by shipping flat, fitting up to three times more units per truckload compared to fully assembled crates. This efficiency lowers both outbound and return freight costs, especially in high-volume supply chains.

When fully assembled crates are shipped, only about 50 may fit per truckload. By contrast, flat-packed knockdown shipping crates can reach 150 per load, significantly reducing transportation expenses. This advantage is amplified for companies in Ohio and the Midwest, where shipping distances between plants, distributors and customers can be long. By choosing knockdown crates, businesses benefit from reduced freight charges, optimized warehouse space and lower overall supply chain costs—while still ensuring safe and durable protection for their products.