Rubber Matting

Back to Load Securement and Protection

Know What You're Looking For?

Need More Help With Your Load?

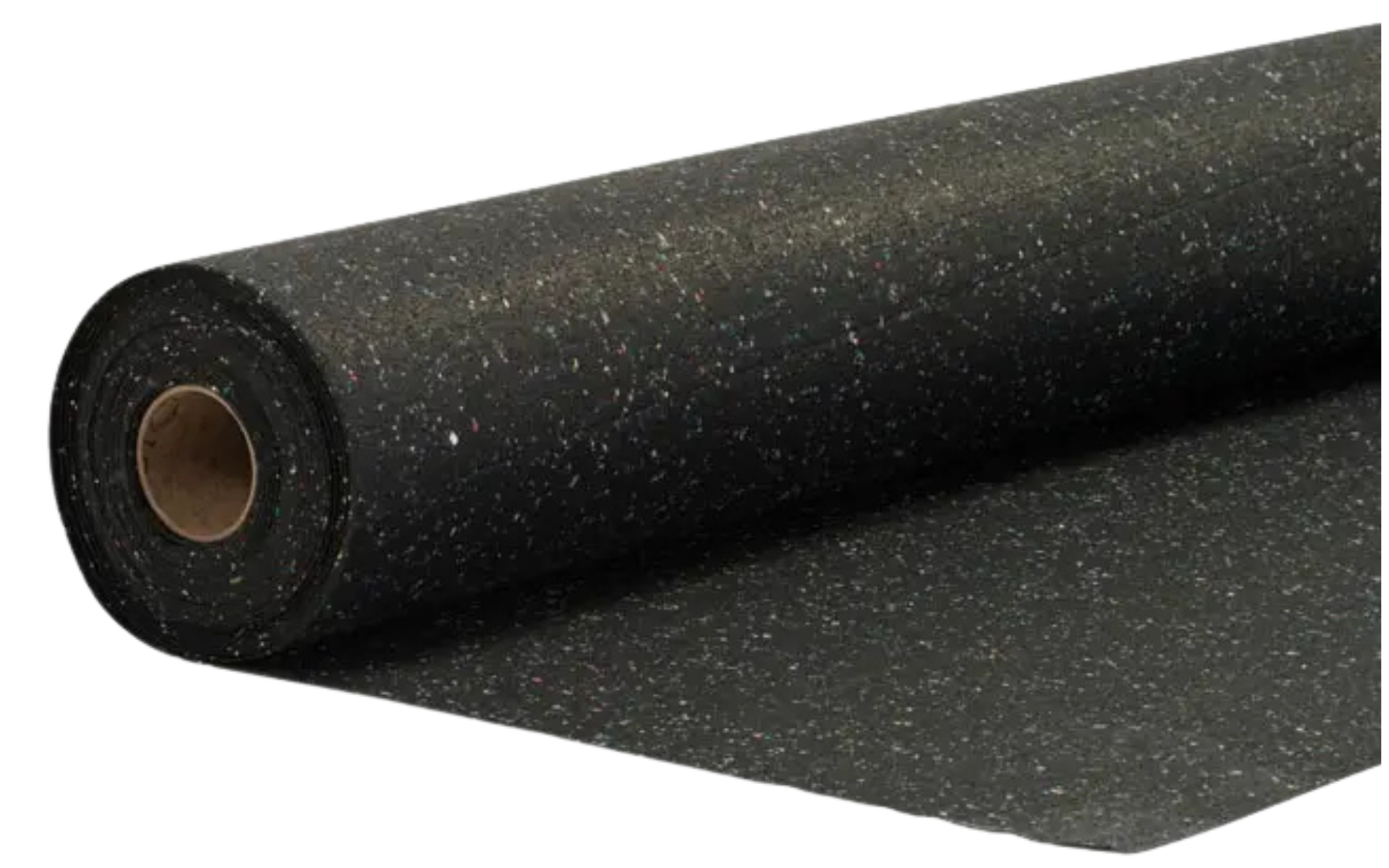

Non-Slip Rubber Matting for Load Securement

Millwood’s rubber matting is a reliable solution for keeping your shipments safe, secure and compliant. Designed from recycled rubber granules and approved by major transportation authorities, these mats create a friction surface that prevents loads from sliding or shifting. Whether for OTR, rail or intermodal transport, our non slip rubber mat delivers performance you can count on.

Why Choose Anti Slip Rubber Mats?

A thin, high grip barrier increases friction between your load and the trailer surface, reducing movement without high contact pressure. Anti slip rubber mats are reusable, cost effective and environmentally friendly.

Flexible Sizes & Easy Handling

Available in sheets or rolls, rubber matting is lightweight, easy to cut and quick to position for optimized pallet patterns. Choose from standard sizes, like 20″ x 36″ or 48″ x 50″ rolls, to fit your shipping needs.

Complex Packaging Needs? No Problem.

- Corner Defender – Reinforces 90° corners and prevents strapping abrasion.

- Edge Defender – Protects edges and strengthens unitization for better stability.

- Notch Defender – Provides durable corner and edge protection for heavy or high-impact loads.

Custom-made to order and 100% recyclable, the Defender Series delivers the protection, strength, and peace of mind your supply chain demands—because at Millwood, we’ve got every corner covered.

Why Choose Millwood As Your Single Source Provider?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Rubber Matting

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify, and optimize designs to reduce product damage, minimize waste, and improve supply chain efficiency.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your damage prevention needs.

Frequently Asked Questions

What is rubber matting for load securement and how does it work?

Rubber matting is a durable, non-slip solution placed beneath cargo to prevent shifting during transport. It increases surface friction, stabilizes loads and provides protection in both dry and wet shipping conditions.

Rubber matting works by creating a high-friction barrier between cargo and trailer floors or pallets. When paired with straps or tie-downs, it resists slippage, even under heavy vibration or sudden stops. Unlike disposable blocking, a non slip rubber mat is reusable and provides reliable, long-term performance. Millwood’s rubber matting ensures maximum stability for industries moving heavy goods such as steel, roofing materials and machinery.

Which industries and cargo types benefit most from rubber matting?

Industries that ship heavy, irregular or outdoor-stored products benefit most from rubber matting. Construction, roofing, steel, lumber and manufacturing companies use it to secure loads and protect shipments from movement.

Cargo types like shingles, pipes, drums, rolls, machinery and coils often shift in transit without proper stabilization. By using an anti slip rubber mat, companies reduce load movement, limit product damage and maintain compliance with shipping regulations. Millwood’s rubber matting is engineered to deliver reliable performance across multiple modes of transportation, making it a versatile choice for demanding industries.

Is rubber matting compliant with load securement regulations?

Yes. Rubber matting is widely recognized as a compliant load securement aid, helping companies meet DOT, FMCSA, AAR and CVSA guidelines for safety in shipping and transport.

Because rubber matting significantly reduces shifting, it often replaces older methods like wood blocking, which can damage trailer floors or goods. A non slip rubber mat provides friction-based restraint that enhances the performance of tie-downs. Millwood ensures its rubber matting solutions meet or exceed safety standards, allowing shippers to reduce risk, avoid fines and improve reliability across road, rail and intermodal shipping.

How does rubber matting compare to wood blocking or bracing?

Rubber matting offers a cleaner, reusable alternative to wood blocking, saving labor, reducing waste and preventing damage. It provides secure, friction-based restraint instead of rigid, one-time bracing.

Unlike wood blocking, which requires cutting, nailing and disposal, rubber matting is reusable and quick to install. An anti slip rubber mat creates dependable grip without damaging trailer floors, while saving valuable loading time. Millwood’s rubber matting provides long-term cost efficiency and consistent performance, making it the superior option for operations needing durable, repeatable load securement solutions.

How do I choose the right thickness or type of rubber matting?

The right rubber matting depends on cargo weight, surface conditions and type of shipment. Heavy or dynamic loads require thicker, denser mats to provide maximum stability and grip.

For lighter or more stable cargo, thinner mats may be sufficient, while heavy machinery, coils or bulk building materials benefit from thicker options. Choosing the right non slip rubber mat ensures proper friction, reduced shifting and extended reuse. Millwood’s team can recommend the best anti slip rubber mat specifications—thickness, density and durability—based on your unique shipping requirements.

Can rubber matting reduce cargo damage and costs?

Yes. Rubber matting minimizes product movement, reducing damage, liability claims and operational costs tied to unstable shipments. It protects both goods and packaging during transport.

By stabilizing pallets, an anti slip rubber mat prevents abrasion, impact and vibration-related damage. This reduces insurance claims, repackaging needs and costly delays. Over time, Millwood’s heavy-duty rubber matting delivers strong ROI by lowering losses while ensuring regulatory compliance. It’s an effective, proven solution for shippers who prioritize protection, efficiency and customer satisfaction.

Stronger Together

Millwood and Litco are affiliated companies, united in mission, purpose and culture. Together, we are strategically aligned to provide a more comprehensive range of pallets, load securement, packaging and supply chain solutions to a broader customer base, delivering greater value to our customers.