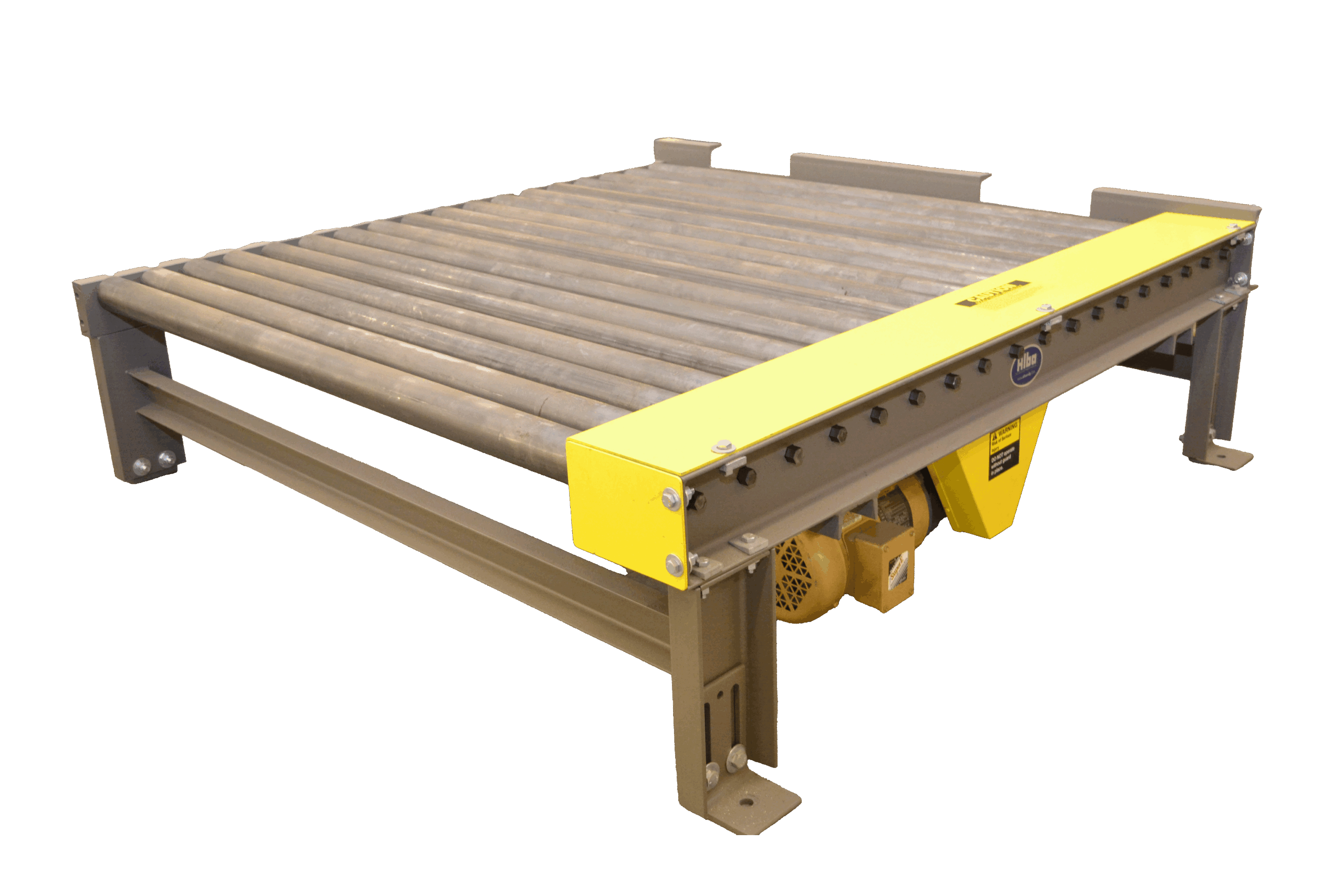

Pallet Conveyor Systems

Request a Quote

Thank you for reaching out about a quote from our team. Please complete the form below and one of our team members will be in touch with you. If you are currently or planning to use this product for multiple applications, please complete the form with the information from your largest load by total dimension. (LxWxH)

Innovative Pallet Conveyor Systems for Efficient Material Handling

Streamline your operations with Millwood’s pallet conveyor systems, designed to optimize pallet handling and improve workflow. From standard installations to custom layouts, our engineered solutions meet the demands of any facility.

Custom Pallet Conveyor System Design

Our in-house engineering team specializes in creating tailored pallet conveyor systems that accommodate specific loads and facility footprints. Whether you need conveyors for cases, bags, beverages or specialty products, we deliver innovative solutions for every application.

Comprehensive Conveying Solutions

Millwood supports your pallet handling needs with full-service solutions, including new installations, system upgrades, maintenance and custom-engineered layouts. Our conveyor systems combine standard components with custom designs to maximize efficiency and reliability.

Custom Requirements? No Problem.

- Under-engineering that can result in pallet failure and product damage

- Over-engineering that drives up unnecessary costs and excess freight weight

- Instead, we deliver a just-right solution—balanced for strength, cost, and performance

Why Choose Millwood as Your Solution Provider?

- Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

- Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

- Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Packaging Systems

We will work to understand the problems you are having and as a team to provide solutions.

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify, and optimize designs to reduce product damage, minimize waste, and improve supply chain efficiency.

System Maintenance

Millwood offers complete pallet recycling programs to retrieve, inspect, recover, and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your packaging needs.

Growing in popularity, they are accessible on all four sides, by either forklifts or pallet jacks.

Rotary arm and rotary ring systems for fragile or heavy loads. Available in semi-automatic or fully automatic options. Keep loads stationary while applying film for speed, safety and consistency.

High-performance stretch wrap engineered for consistency, efficiency and speed in automated or semi-automated pallet wrapping systems.

Frequently Asked Questions

What is a pallet conveyor system?

A pallet conveyor system is equipment designed to move pallets automatically through warehouses or production lines.

These systems use rollers, chains or belts to transport pallets of goods safely and efficiently, replacing manual handling and forklifts for repetitive movement. By automating pallet transport, conveyor systems reduce labor costs, minimize product damage and streamline material flow across facilities. They are widely used in industries such as food and beverage, logistics, building materials and pharmaceuticals. Custom configurations allow businesses to align pallet conveyors with existing operations, ensuring seamless handling of heavy loads and compatibility with automated packaging or storage systems.

What are the benefits of pallet conveyor systems?

Pallet conveyor systems improve efficiency, reduce labor costs and ensure safer handling of heavy loads.

By automating repetitive pallet movement, conveyor systems cut down on forklift traffic, lowering accident risks and operational delays. They also enhance throughput by maintaining a continuous flow of goods, reducing downtime in packaging and distribution processes. Long-term, pallet conveyor equipment supports consistent productivity while lowering product damage risks. Automated conveyors are particularly valuable in high-volume environments where efficiency gains directly impact profitability. For businesses seeking sustainability, conveyors can also reduce energy use compared to forklifts, supporting ESG and operational goals.

How do pallet conveyor systems improve supply chain efficiency?

Pallet conveyor systems streamline operations by ensuring faster, safer and more predictable pallet movement.

By automating pallet handling, conveyor systems create a smoother flow of goods from production lines to warehouses and distribution centers. This reduces bottlenecks, improves order fulfillment speed and allows companies to handle higher volumes without additional labor. With precise pallet routing, conveyors enhance supply chain visibility and consistency. They also minimize product handling errors and damage during transport. Combined with automation, conveyor systems support lean manufacturing, reduce lead times and help companies stay competitive in industries where speed and reliability are critical.

What types of pallet conveyor systems are available?

Common types of pallet conveyors include roller conveyors, chain conveyors and automated transfer systems.

Roller conveyors are versatile and suited for stable, heavy pallet loads, while chain conveyors handle very heavy or unevenly distributed loads. Automated transfer conveyors integrate with robotic or automated storage systems to streamline pallet routing. Each type of pallet handling system can be customized to fit floor layouts, throughput requirements and safety standards. Many operations use a mix of conveyor types to optimize efficiency. Selecting the right conveyor depends on pallet size, load weight and whether integration with packaging or automated storage is required.

What industries benefit most from pallet conveyor systems?

Pallet conveyor systems are used in logistics, manufacturing, food & beverage, pharmaceuticals and building materials.

These industries rely heavily on pallet conveyors to manage large volumes of goods safely and efficiently. For example, logistics centers use conveyors to handle incoming and outgoing pallets for distribution. Food and beverage companies integrate conveyors into packaging lines for reliable material flow. Pharmaceuticals depend on conveyor automation for clean, precise handling under strict compliance standards. In heavy industries like building materials, conveyors reduce labor demands and keep operations moving despite heavy loads. The versatility of pallet conveyor equipment makes it adaptable across almost every major industry that uses palletized goods.