Void Fill Panels

Back to Load Securement and Protection

Custom Engineered Void Fill Panels to Optimize Cargo Securement

Corrugated panels that prevent lateral shifting, reduce air bag void space and add pallet underhang support. Lightweight yet strong and fully recyclable.

Load dividers that block side-to-side or forward movement, support stacking efficiency and replace heavy plywood alternatives.

Recyclable solution engineered to stabilize freight in 53’ OTR trailers by filling nose voids and preventing forward shift. Durable, reinforced and eco-friendly.

What Makes Millwood Void Fill Panels Different?

Millwood brings decades of packaging engineering and logistics experience to every void fill solution. Our panels are trusted by leading shippers because they provide measurable performance improvements in safety, speed and sustainability. We approach every project as a partnership, designing each panel to perform consistently across transport types and conditions.

Every void fill panel is tested in our ISTA-certified lab to verify compression strength, deflection and real-world performance. This engineering validation ensures your packaging investment performs exactly as expected — shipment after shipment. Combined with our national production network and commitment to sustainable design, Millwood panels deliver protection you can depend on.

Key Advantages of Millwood Void Fill Panels:

-

Validated Performance: Lab-tested to meet load containment and compression standards

-

Custom Engineering: Tailored designs based on load type, weight and trailer conditions

-

Sustainable Design: Made from recyclable materials under Perfect Stewardship practices

-

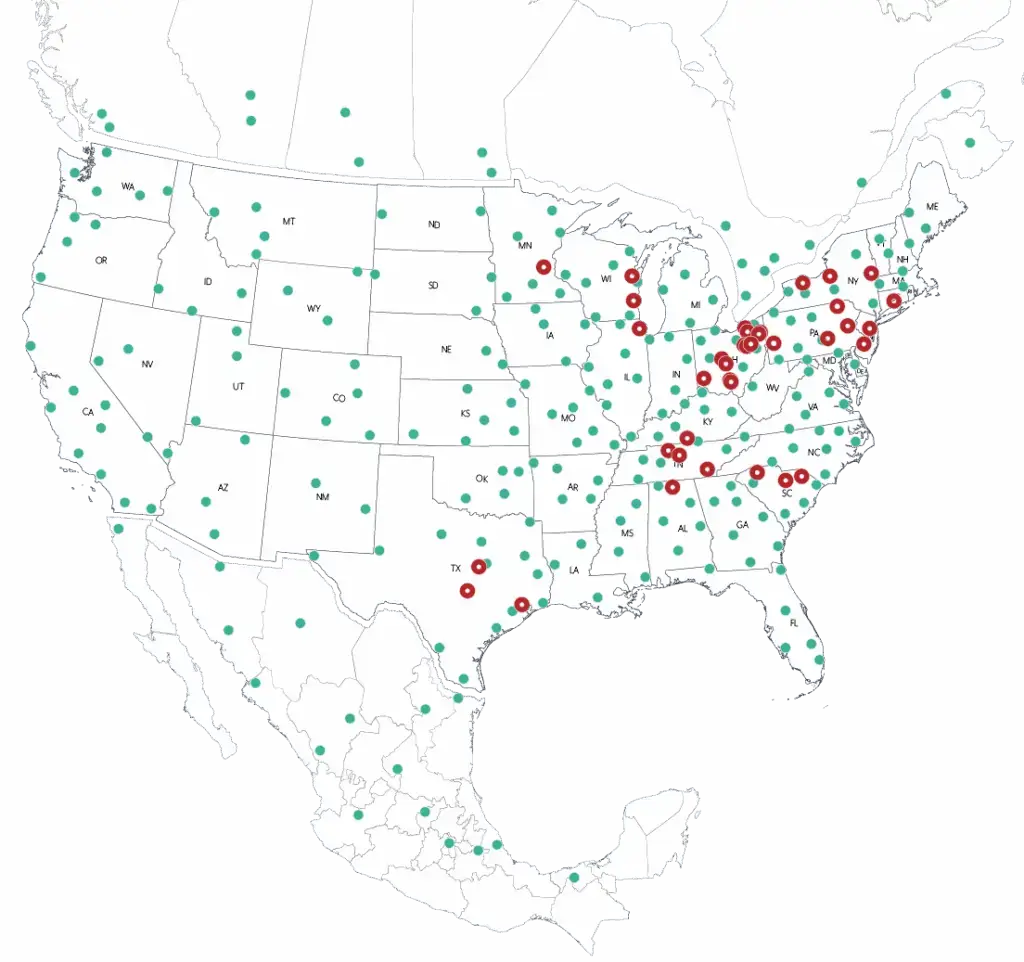

Nationwide Reliability: Supported by 37 facilities and 250+ partners for consistent supply

-

Proven Partnership: Backed by decades of packaging innovation and supply chain expertise

When you partner with Millwood, you gain an experienced ally dedicated to safeguarding your products and optimizing your shipping operations.

3 WAYS MILLWOOD MAKES BUYING LOAD SECUREMENT EQUIPMENT EASY

We Listen & Understand

Your load patterns, trailer types and operational needs are unique. We take the time to evaluate gaps and challenges before recommending the right panel type.

We Test First & Build Right

Every void fill panel is engineered and validated in our ISTA-certified lab. By simulating real shipping conditions, we confirm performance before rollout, cutting claims and reducing long-term costs

We Deliver Consistently

With more than 30 facilities and 250+ partners, Millwood ensures you get the right panels where and when you need them—backed by reliable supply and competitive pricing.

Leveraging Our Experience to Serve You.

We know customers want partners who provide consistent quality, reliable availability and competitive pricing. Millwood brings decades of packaging expertise beyond pallets into void fill panel solutions, guided by three principles:

Source and Supply

With 37 strategically located manufacturing and repair facilities, 250+ strategic partners across North America and 1.5 million square feet of manufacturing and distribution space, Millwood controls its supply chain from the forest to the finished product. We handle more than 200,000,000 pallets and process over 100,000,000 board feet of lumber per year. Our vertically integrated operations ensure quality and reliable supply for our customers.

Exceptional Service

Serving others is our highest aim. Our dedicated customer support team delivers personal attention, not automated replies, with the care, integrity and expertise you deserve. We prioritize people by listening to your questions and concerns to provide the best support. When you connect with Millwood, you can expect an experience marked by professional care and genuine responsiveness. Trust us for consistent, customer-focused service that truly exceeds your expectations.

Sustainable

Operating under a culture of Perfect Stewardship, Millwood is committed to efficiency without compromise to our environment. From the way that our trees are harvested to our innovative line of sustainable packaging products and numerous recycling programs, we will work with you to reduce waste and meet your sustainability goals. Partner with us for sustainable solutions that support your business while protecting our planet.

Providing Comprehensive Load Securement Solutions That Scale as Your Business Grows

LET’S BUILD TOGETHER

Building strategically with Millwood means having a partner who can grow with you—no matter your size or goals. Whether you’re operating two locations or two hundred, choosing Millwood is a smart move because we are built for scale. We serve some of the nation’s largest brands and know how to support growth at every stage, from startups expanding rapidly to industry leaders adding facilities nationwide. That scalability ensures your packaging and pallet supply stays reliable and efficient as your business evolves.

We make scaling simple because we understand multi-location needs and service them with one integrated solution. Our nationwide reach and proven processes mean you don’t have to manage different suppliers for each region—we take care of it all. When time is critical and your business is growing fast, our ability to deliver consistently, at scale, across multiple facilities makes us a strategic partner you can count on.

Millwood is more than a pallet supplier—we’re a one-stop packaging solutions partner. From pallets to load securement, recycling solutions, and strategic sourcing, we help optimize your supply chain and support your sustainability goals. Whether you buy 500 pallets a month or 5 million, we have the infrastructure, expertise, and flexibility to scale with you. Partnering with Millwood means you gain a reliable ally who helps you focus on your growth while we handle your packaging needs. We would look forward to talking with you to see how we can help serve you.

As part of our Load Securement & Protection product line, Millwood’s Corner Protectors are designed to protect products from dents, strapping abrasions and shipping and handling damage.

Millwood Lab

ISTA-certified testing ensures every void fill panel performs under real shipping and handling conditions. We verify stability, reduce damage and help you avoid over- or under-engineering.

PalletView

Track the quantity and condition of various managed assets such as pallets, tier sheets, plastic dunnage and airbags with PalletView, our proprietary web-based application.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

See How We've Helped Others

When a national packaging provider faced rising freight costs, safety risks and product damage from inconsistent crate construction, they needed a scalable solution. Working together, we and our partner engineered an integrated packaging system that combined corner protection with custom crate design to strengthen performance and eliminate inefficiencies.

Through collaboration, testing and process control, we delivered consistent quality, improved safety and reduced total cost per unit — proving that partnership drives stronger results than competition ever could.

- Reduced total cost per unit by 10% through optimized crate design and stacking efficiency

- Shipped 3.4 million linear feet of product annually with zero safety incidents since launch

- Delivered consistent, high-quality protection through a unified engineering and supply approach

Reliable. Available. Local.

We understand it is important to know that your pallets will be delivered on time, every time. That's why we are where you are.

Frequently Asked Questions

Void fill panels are engineered fiberboard or corrugated sheets designed to fill empty spaces between loads and prevent shifting.

They improve load stability inside trailers, containers and railcars by creating secure bracing between pallets or irregular cargo. Millwood’s panels are lightweight, recyclable and reusable, offering dependable protection with easy installation. Tested in our ISTA-certified lab, they deliver consistent containment, reduce freight claims and help improve handling efficiency throughout your supply chain.

They install faster, require no inflation tools and are fully recyclable for sustainable load protection.

Airbags require air systems, while foam is bulky and difficult to reuse. Millwood’s void fill panels expand load stability instantly, collapsing flat after use for compact storage. Their design eliminates disposal challenges while maintaining strength under compression. This reusable approach reduces labor, improves efficiency and supports sustainability by removing single-use materials from your packaging workflow.

Yes. Each panel is engineered to your specific trailer, pallet and freight needs.

Millwood’s engineering team adjusts dimensions, strength and material type based on your load configuration. Our ISTA-certified lab tests every prototype for compression, vibration and impact performance. This custom validation ensures every panel meets your operational and safety goals while maintaining efficiency and compliance across your logistics network.

Any industry shipping palletized, mixed or sensitive loads benefits from void fill panels.

Manufacturers, distributors and logistics providers rely on them to improve stability, prevent freight damage and meet compliance standards. Whether used in over-the-road or intermodal transport, Millwood’s solutions reduce product loss, enhance handling safety and support sustainable shipping practices across diverse product categories and load types.

Yes. Millwood’s void fill panels are designed for multiple uses and are fully recyclable at end-of-life.

Manufactured from durable corrugated or fiberboard materials, each panel withstands repeated handling and compression. After use, they fold or stack flat for efficient storage and redeployment. When retired, panels can be recycled through standard recovery programs, lowering waste and costs. This reusability makes them ideal for companies prioritizing long-term sustainability and improved packaging ROI.

Yes. Millwood manufactures and distributes void fill panels through 37 facilities and 250+ partner sites across North America.

This reach ensures consistent quality, faster lead times and reliable delivery. Our vertically integrated supply chain supports customers from single-location shippers to national operations, offering the same dependable packaging solutions wherever your business operates.

Stronger Together

Millwood and Litco are affiliated companies, united in mission, purpose and culture. Together, we are strategically aligned to provide a more comprehensive range of pallets, load securement, packaging and supply chain solutions to a broader customer base, delivering greater value to our customers.