Stretch Wrappers

Custom Engineered Stretch Wrapping Systems to Optimize Your Supply Chain

Semi-automatic and automatic turntable systems that spin pallets during wrapping. Efficient, uniform load containment for low- to high-volume operations.

Rotary arm and rotary ring systems for fragile or heavy loads. Available in semi-automatic or fully automatic options. Keep loads stationary while applying film for speed, safety and consistency.

Portable, semi-automatic machines that travel around pallets of any size, shape or weight. Advanced pre-stretch controls, film cut and Industry 4.0 connectivity for real-time monitoring.

What Makes Millwood Stretch Wrapping Machines Different?

Millwood’s stretch wrapping machines combine robust engineering with proven reliability to create efficient, automated solutions for every packaging environment. We understand that speed, uptime and consistency are critical to your operation. That’s why our equipment is built to perform under continuous demand while optimizing film usage and ensuring load integrity.

From design to installation, every system is tested and configured to meet your production goals. Our technical team validates each wrapper for safety, throughput and containment performance. Backed by Millwood’s national network and Perfect Stewardship commitment, you gain equipment that supports your sustainability and productivity objectives.

Key Advantages of Millwood Stretch Wrapping Machines:

-

Validated Results: Engineered and tested to meet containment standards while reducing film use

-

Custom Integration: Configured to your conveyor layout, product size and throughput goals

-

Reliable Performance: Designed for durability, low maintenance and continuous uptime

-

Sustainable Solutions: Optimize stretch ratios and film efficiency to reduce waste

-

Nationwide Support: Backed by Millwood’s service network and trained technicians

When you partner with Millwood, you gain a trusted packaging partner dedicated to protecting your products and improving your bottom line.

3 WAYS MILLWOOD MAKES BUYING STRETCH WRAPPING MACHINES EASY

We Listen & Understand

Every warehouse and production line is different. We learn your throughput, load stability needs and space constraints before recommending the right machine.

We Test First & Build Right

Our ISTA-certified lab simulates real-world shipping and handling conditions to confirm performance. We ensure your stretch wrapper matches your load requirements and film type, reducing risk and wasted spend

We Deliver Consistently

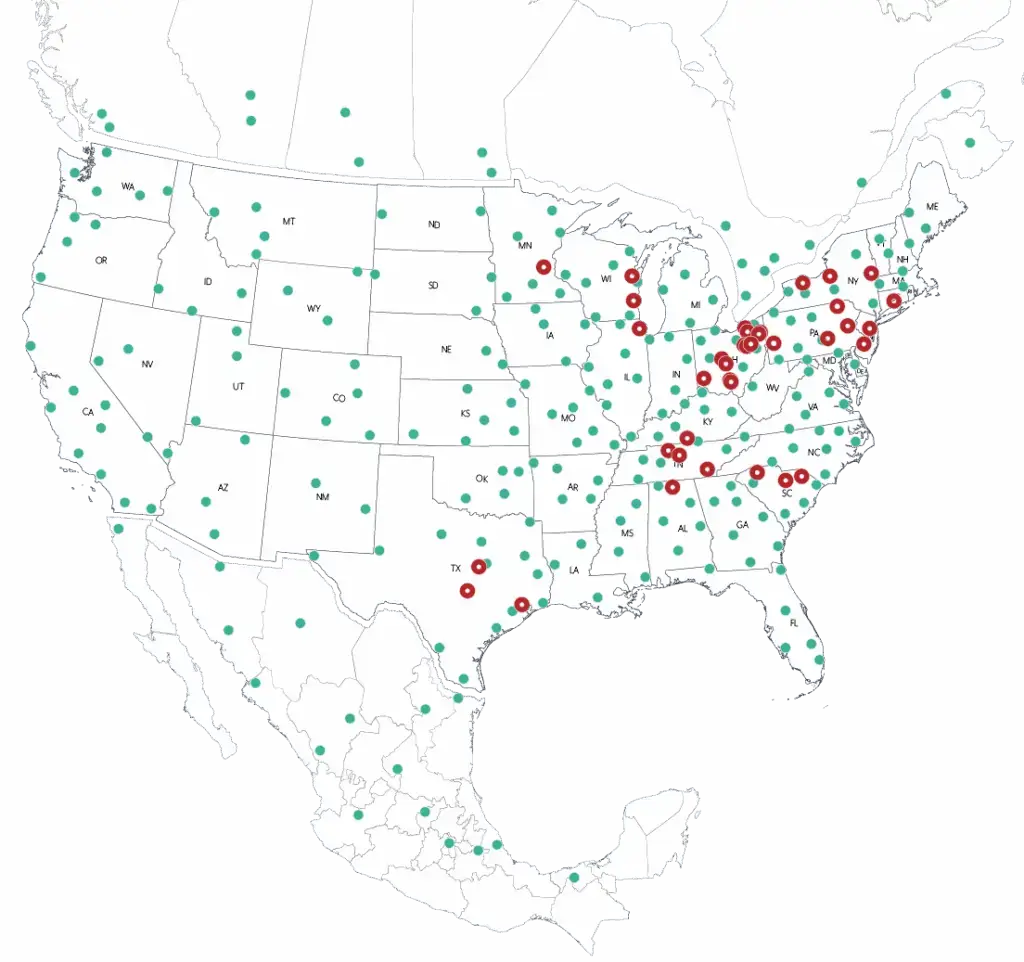

With 40+ facilities and 250+ partners, Millwood provides reliable supply, service, and support—so your operations run without costly interruptions.

Leveraging Our Experience to Serve You

We understand customers choosing stretch wrapping machines need more than hardware—they need a partner who can deliver consistent quality, on-time service and competitive pricing.

Source and Supply

With 37 strategically located manufacturing and repair facilities, 250+ strategic partners across North America and 1.5 million square feet of manufacturing and distribution space, Millwood controls its supply chain from the forest to the finished product. We handle more than 200,000,000 pallets and process over 100,000,000 board feet of lumber per year. Our vertically integrated operations ensure quality and reliable supply for our customers.

Exceptional Service

Serving others is our highest aim. Our dedicated customer support team delivers personal attention, not automated replies, with the care, integrity and expertise you deserve. We prioritize people by listening to your questions and concerns to provide the best support. When you connect with Millwood, you can expect an experience marked by professional care and genuine responsiveness. Trust us for consistent, customer-focused service that truly exceeds your expectations.

Sustainable

Operating under a culture of Perfect Stewardship, Millwood is committed to efficiency without compromise to our environment. From the way that our trees are harvested to our innovative line of sustainable packaging products and numerous recycling programs, we will work with you to reduce waste and meet your sustainability goals. Partner with us for sustainable solutions that support your business while protecting our planet.

Providing Comprehensive Stretch Wrapping Solutions That Scale as Your Business Grows

LET’S BUILD TOGETHER

Building strategically with Millwood means having a partner who can grow with you—no matter your size or goals. Whether you’re operating two locations or two hundred, choosing Millwood is a smart move because we are built for scale. We serve some of the nation’s largest brands and know how to support growth at every stage, from startups expanding rapidly to industry leaders adding facilities nationwide. That scalability ensures your packaging and pallet supply stays reliable and efficient as your business evolves.

We make scaling simple because we understand multi-location needs and service them with one integrated solution. Our nationwide reach and proven processes mean you don’t have to manage different suppliers for each region—we take care of it all. When time is critical and your business is growing fast, our ability to deliver consistently, at scale, across multiple facilities makes us a strategic partner you can count on.

Millwood is more than a pallet supplier—we’re a one-stop packaging solutions partner. From pallets to load securement, recycling solutions, and strategic sourcing, we help optimize your supply chain and support your sustainability goals. Whether you buy 500 pallets a month or 5 million, we have the infrastructure, expertise, and flexibility to scale with you. Partnering with Millwood means you gain a reliable ally who helps you focus on your growth while we handle your packaging needs. We would look forward to talking with you to see how we can help serve you.

As part of our Load Securement & Protection product line, Millwood’s Corner Protectors are designed to protect products from dents, strapping abrasions and shipping and handling damage.

Millwood Lab

Our ISTA-certified test lab validates stretch wrapper performance under real shipping conditions—ensuring consistency, stability and cost savings.

PalletView

Track the quantity and condition of various managed assets such as pallets, tier sheets, plastic dunnage and airbags with PalletView, our proprietary web-based application.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

See How We've Helped Others

A global building materials manufacturer struggled with 14 pallet specs across multiple vendors, creating waste, product damage and inefficiency. They needed a partner who could simplify sourcing and scale reliably as they grew.

By consolidating with us and standardizing one optimized pallet spec through lab testing and vendor management, the company achieved unmatched consistency, quality and delivery performance — turning complexity into a long-term advantage.

- Standardized one optimized pallet spec from 14 originals

- Deliver over 3 million pallets annually with 99.9% on-time performance

- Maintained 100% quality satisfaction since the 1980s through innovation and partnership

Reliable. Available. Local.

We understand it is important to know that your pallets will be delivered on time, every time. That's why we are where you are.

Frequently Asked Questions

A stretch wrapping machine automates the process of applying stretch film around pallet loads to improve stability and prevent shifting.

By standardizing film application, these machines reduce waste, improve load containment and increase efficiency compared to manual wrapping. Options include turntable, overhead and robotic systems, each suited to different load types and volumes.

Millwood offers three main types: overhead (rotary arm/ring), robotic and turntable. Each provides unique benefits.

Overhead models keep pallets stationary, ideal for fragile or unstable loads. Robotic systems offer portable flexibility across pallets of any size. Turntables provide cost-efficient automation for low- to high-volume lines. Millwood helps match the right solution to your operation.

Automatic wrappers increase throughput by reducing manual labor and standardizing wrap patterns.

Features such as film pre-stretch, auto film cut and programmable wrap cycles optimize film use, reduce waste and improve load consistency. Facilities wrapping 40+ loads per hour benefit most from automated systems.

They’re used by manufacturing, distribution, food, beverage and logistics companies across the U.S.

Millwood’s machines handle diverse load types, from fragile goods to industrial products. We help customers standardize packaging operations, reduce labor costs and ensure load stability throughout transit. Our systems are trusted in facilities where reliability and consistency are non-negotiable.

Yes. Each system is configured to your line layout, product mix and load requirements.

Millwood engineers every machine for compatibility with your existing conveyors, pallet sizes and production speeds. Our technical team provides site assessments, load testing and full integration planning to ensure seamless installation. This customization delivers maximum uptime and reliable performance tailored to your facility.

Yes. Millwood offers complete installation, maintenance and technical support across North America.

Our network of 37 facilities and 250+ partners ensures prompt response and consistent service. From initial setup to long-term upkeep, our technicians keep your systems running at peak efficiency. Customers benefit from reliable nationwide coverage backed by a people-first service philosophy focused on uptime and satisfaction.