Ergonomic Lifting Equipment

Custom Engineered Ergonomic Equipment to Improve Safety and Efficiency

Advanced hydraulic lift table that raises and lowers loads smoothly. Reduces operator strain, improves safety and adapts to warehouse, manufacturing and distribution environments.

Portable pallet lifter combining ergonomic lift table design with mobile flexibility. Ideal for safe, efficient handling in tight spaces across industries.

Spring pallet positioner that automatically adjusts pallet height and rotates for near-side access. Reduces bending and lifting with no installation or power required.

Heavy-duty pallet inverter machine that rotates loads up to 180°. Enables quick pallet changes, product swaps and slip sheet transfers without manual restacking.

What Makes Millwood Ergonomic Equipment Different?

Millwood understands that material handling safety is essential for both people and productivity. That’s why our ergonomic lifting solutions are designed to prevent injuries and streamline operations through thoughtful engineering and reliable performance. Each Liberty system is tested for balance, stability and durability, ensuring years of dependable use in demanding environments.

We integrate ergonomic design principles into every piece of lifting equipment we produce. From hydraulic lifters to spring positioners, each product undergoes lab validation for load capacity, mechanical efficiency and worker safety. Our solutions empower teams to move materials faster and safer — with less fatigue and more consistency.

Key Advantages of Millwood Ergonomic Lifting Equipment:

-

Validated Safety: Tested to reduce strain, fatigue and injury risk across operations

-

Custom Engineering: Configured for specific load capacities and floor conditions

-

Durable Construction: Built from industrial-grade steel for reliable performance

-

Power-Free Options: Spring and air-powered systems that need no installation

-

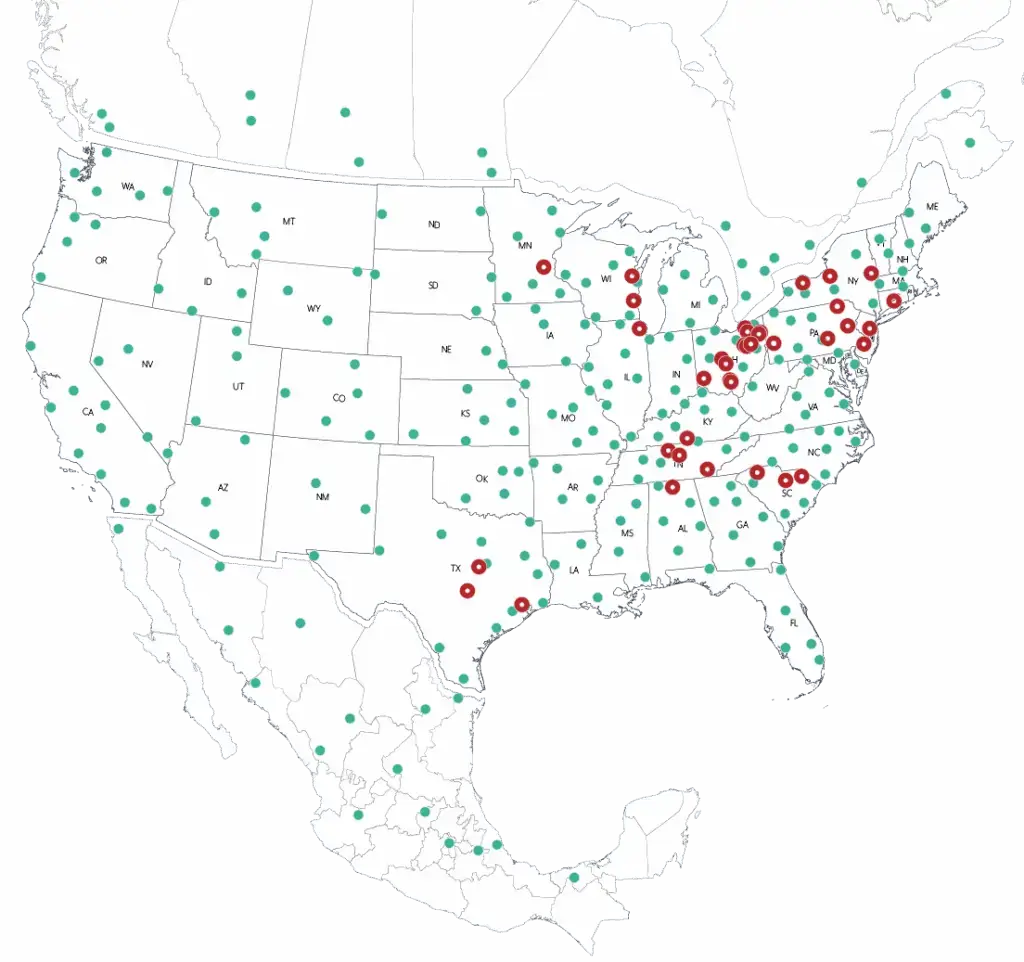

Nationwide Reliability: Supported by 37 facilities and 250+ partners for fast delivery

When you partner with Millwood, you gain more than equipment — you gain a trusted team committed to keeping your workforce safe and productive.

3 WAYS MILLWOOD MAKES BUYING ERGONOMIC EQUIPMENT EASY

We Listen & Understand

We evaluate your workflows, lifting challenges and facility constraints to recommend the right ergonomic material handling solutions.

We Test First & Build Right

Our equipment is engineered and validated to perform reliably under your unique applications, ensuring safety and long-term value.

We Deliver Consistently

With 40+ facilities and 250+ partners, Millwood provides reliable equipment, installation and service across North America.

Leveraging Our Experience to Serve You

Customers choosing ergonomic lifting equipment expect more than just machines—they want a trusted partner for safety, productivity and cost savings. Millwood delivers with three guiding principles:

Source and Supply

With 37 strategically located manufacturing and repair facilities, 250+ strategic partners across North America and 1.5 million square feet of manufacturing and distribution space, Millwood controls its supply chain from the forest to the finished product. We handle more than 200,000,000 pallets and process over 100,000,000 board feet of lumber per year. Our vertically integrated operations ensure quality and reliable supply for our customers.

Exceptional Service

Serving others is our highest aim. Our dedicated customer support team delivers personal attention, not automated replies, with the care, integrity and expertise you deserve. We prioritize people by listening to your questions and concerns to provide the best support. When you connect with Millwood, you can expect an experience marked by professional care and genuine responsiveness. Trust us for consistent, customer-focused service that truly exceeds your expectations.

Sustainable

Operating under a culture of Perfect Stewardship, Millwood is committed to efficiency without compromise to our environment. From the way that our trees are harvested to our innovative line of sustainable packaging products and numerous recycling programs, we will work with you to reduce waste and meet your sustainability goals. Partner with us for sustainable solutions that support your business while protecting our planet.

Providing Comprehensive Ergonomic Solutions That Scale as Your Business Grows

LET’S BUILD TOGETHER

Building strategically with Millwood means having a partner who can grow with you—no matter your size or goals. Whether you’re operating two locations or two hundred, choosing Millwood is a smart move because we are built for scale. We serve some of the nation’s largest brands and know how to support growth at every stage, from startups expanding rapidly to industry leaders adding facilities nationwide. That scalability ensures your packaging and pallet supply stays reliable and efficient as your business evolves.

We make scaling simple because we understand multi-location needs and service them with one integrated solution. Our nationwide reach and proven processes mean you don’t have to manage different suppliers for each region—we take care of it all. When time is critical and your business is growing fast, our ability to deliver consistently, at scale, across multiple facilities makes us a strategic partner you can count on.

Millwood is more than a pallet supplier—we’re a one-stop packaging solutions partner. From pallets to load securement, recycling solutions, and strategic sourcing, we help optimize your supply chain and support your sustainability goals. Whether you buy 500 pallets a month or 5 million, we have the infrastructure, expertise, and flexibility to scale with you. Partnering with Millwood means you gain a reliable ally who helps you focus on your growth while we handle your packaging needs. We would look forward to talking with you to see how we can help serve you.

As part of our Load Securement & Protection product line, Millwood’s Corner Protectors are designed to protect products from dents, strapping abrasions and shipping and handling damage.

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify and optimize designs to reduce product damage, minimize waste and improve supply chain efficiency.

PalletView

Track the quantity and condition of various managed assets such as pallets, tier sheets, plastic dunnage and airbags with PalletView, our proprietary web-based application.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability.

See How We've Helped Others

A global building materials manufacturer struggled with 14 pallet specs across multiple vendors, creating waste, product damage and inefficiency. They needed a partner who could simplify sourcing and scale reliably as they grew.

By consolidating with us and standardizing one optimized pallet spec through lab testing and vendor management, the company achieved unmatched consistency, quality and delivery performance — turning complexity into a long-term advantage.

- Standardized one optimized pallet spec from 14 originals

- Deliver over 3 million pallets annually with 99.9% on-time performance

- Maintained 100% quality satisfaction since the 1980s through innovation and partnership

Reliable. Available. Local.

We understand it is important to know that your pallets will be delivered on time, every time. That's why we are where you are.

Frequently Asked Questions

Ergonomic lifting equipment includes devices like pallet inverters, lifters and positioners that reduce strain during material handling.

These systems support safer, more efficient movement of heavy goods by keeping loads at optimal working heights and minimizing bending, lifting and twisting. Millwood’s Liberty line offers both powered and spring-assisted options designed for warehouse, manufacturing and distribution environments. They help reduce injuries, improve efficiency and support compliance with workplace safety standards.

It reduces strain and repetitive motion injuries while increasing handling speed and accuracy.

By keeping loads at waist height and eliminating manual lifting, ergonomic equipment limits fatigue and prevents musculoskeletal injuries. Workers move materials faster, maintain better posture and handle more cycles per shift. The result is improved throughput, lower injury rates and a more motivated workforce — a measurable win for safety and productivity.

Ergonomic equipment benefits any facility handling palletized or heavy goods daily.

Manufacturing, distribution, food and beverage and logistics operations all use ergonomic systems to reduce worker fatigue and injury. Whether improving workstation efficiency or simplifying pallet transfers, Millwood’s solutions protect employees and strengthen productivity across every shift.

Yes. Millwood engineers each system to fit your load requirements, workspace and workflow.

We consider capacity, footprint, mobility and safety factors to design the ideal configuration. Customization ensures that each system performs reliably and integrates smoothly into your processes. With in-house testing and nationwide support, Millwood delivers equipment that works exactly where and how you need it.

A pallet inverter automates load transfer safely and efficiently, removing the strain, time and risk of manual restacking.

Manual restacking often requires workers to lift, shift and realign heavy products by hand — a process that slows operations and increases the risk of injury or product damage. A pallet inverter performs the same task in seconds, rotating entire loads 180° for fast pallet replacement or exchange. This eliminates repetitive motion, protects product integrity and improves workflow efficiency. Millwood’s Liberty Inverter is built for durability and ease of use, giving facilities a dependable, ergonomic solution that saves labor while maintaining safety and productivity standards across every shift.

Yes. Millwood provides nationwide equipment delivery, installation and technical service through a trusted, responsive network.

With 37 manufacturing facilities and more than 250 partners across North America, Millwood ensures fast delivery and reliable support for all ergonomic lifting and load securement systems. Our logistics network allows for consistent quality and short lead times, regardless of your location. Customers benefit from hands-on installation, operator training and ongoing maintenance programs designed to maximize uptime and performance. Every project is backed by Millwood’s commitment to service excellence, ensuring your equipment runs safely, efficiently and in full alignment with your facility’s operational needs.