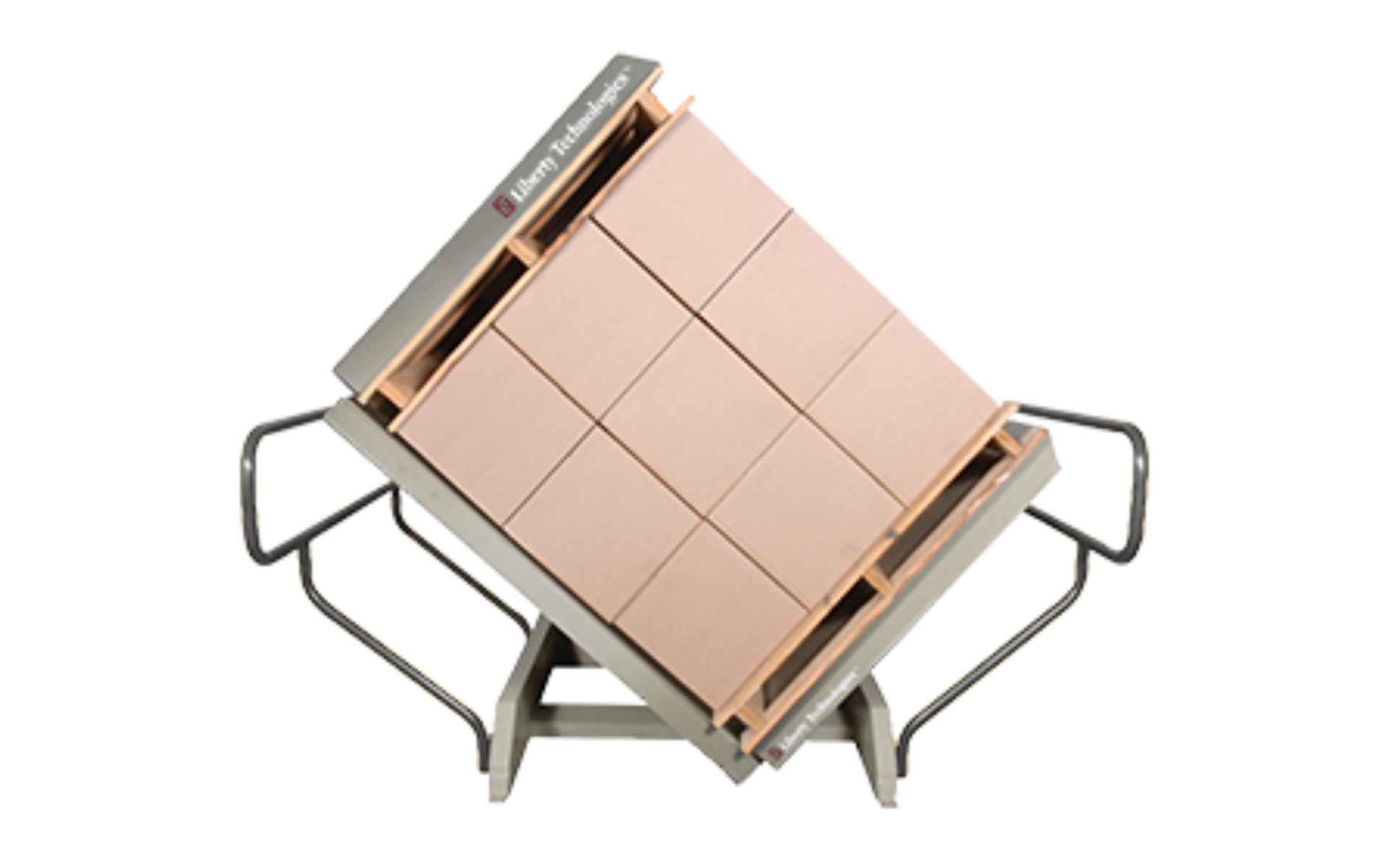

Liberty Inverter

Request a Quote

Thank you for reaching out about a quote from our team. Please complete the form below and one of our team members will be in touch with you. If you are currently or planning to use this product for multiple applications, please complete the form with the information from your largest load by total dimension. (LxWxH)

Industrial Lift Tables for Smarter Load Handling

The Liberty Inverter is a powerful pallet inverter machine built using industrial lift tables to improve safety and efficiency in any warehouse or production environment. This versatile load handling system rotates pallet loads up to 180 degrees, making it simple to replace damaged products, exchange pallets or transfer loads to slip sheets—all without the need for manual restacking.

Boost Productivity with Safer Pallet Handling

By eliminating the time-consuming process of unloading and reloading by hand, the Liberty Inverter increases productivity while protecting workers from repetitive strain injuries. This pallet inverter machine ensures that damaged goods can be swapped out quickly and that shipping or in-house pallets can be exchanged with ease.

Durable, Flexible, and Easy to Relocate

Built for heavy-duty use, the Liberty Inverter includes integrated fork pockets for simple relocation by forklift and comes with a two-year parts and labor warranty. It’s a proven, cost-effective load handling system that keeps operations running smoothly.

Custom Requirements? No Problem.

- Under-engineering that can result in pallet failure and product damage

- Over-engineering that drives up unnecessary costs and excess freight weight

- Instead, we deliver a just-right solution—balanced for strength, cost, and performance

Why Choose Millwood as Your Solution Provider?

- Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

- Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

- Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Packaging Systems

We will work to understand the problems you are having and as a team to provide solutions.

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify, and optimize designs to reduce product damage, minimize waste, and improve supply chain efficiency.

System Maintenance

Millwood offers complete pallet recycling programs to retrieve, inspect, recover, and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your packaging needs.

Advanced hydraulic lift table that raises and lowers loads smoothly. Reduces operator strain, improves safety and adapts to warehouse, manufacturing and distribution environments.

Portable pallet lifter combining ergonomic lift table design with mobile flexibility. Ideal for safe, efficient handling in tight spaces across industries.

Spring pallet positioner that automatically adjusts pallet height and rotates for near-side access. Reduces bending and lifting with no installation or power required.

Frequently Asked Questions

What is a pallet inverter machine?

A pallet inverter machine rotates entire pallet loads to replace, switch or transfer products quickly and safely.

Pallet inverters are designed to handle full pallet loads by rotating them up to 180 degrees. This makes it easy to replace damaged pallets, switch between export and in-house pallets, or re-stack unstable loads. By eliminating manual re-stacking, businesses reduce worker strain, improve handling safety and streamline operations. Pallet inverters are especially valuable in high-volume warehouses where speed, safety and efficiency matter most.

Why should warehouses use a heavy-duty pallet inverter?

Heavy-duty pallet inverters improve efficiency by reducing manual labor, protecting products and saving time during load transfers.

Instead of requiring workers to manually unload and reload products, heavy-duty pallet inverters rotate entire loads in seconds. This reduces injury risk, product damage and costly downtime. Warehouses that regularly switch pallets — such as when moving between wood and plastic pallets for export — save significant time and labor costs. The durability of heavy-duty pallet inverter equipment also ensures reliable performance even under high-volume demands, making it a long-term investment in operational efficiency.

Which industries use pallet inverter machines?

Pallet inverter machines are used across industries like food, pharmaceuticals, retail and logistics where pallet changes are frequent.

Many industries need to transfer goods between pallets for hygiene, regulatory or logistical reasons. Food and pharmaceutical companies often switch loads to meet export standards or replace soiled pallets. Retail distribution centers use pallet inverters to protect goods during transfers and maintain efficiency during high-volume shipping. Logistics and 3PL providers rely on pallet inverters to streamline handling and reduce labor costs across multiple facilities. Any operation that requires frequent pallet swaps benefits from reliable pallet inverter equipment.

How does a pallet load inverter improve efficiency?

A pallet load inverter improves efficiency by automating pallet changes, reducing downtime and minimizing worker fatigue.

Instead of dedicating hours to manually transferring goods, pallet inverter machines perform the process in a matter of minutes. This translates into faster turnaround, higher throughput and lower injury risks. By reducing repetitive manual handling, pallet inverter machines also extend workforce productivity while improving product safety. For companies handling fragile goods, this minimizes breakage and ensures better quality control. Ultimately, pallet load inverters allow businesses to do more with fewer resources, strengthening supply chain efficiency.

What should you consider when choosing a pallet inverter machine?

When choosing a pallet inverter, consider load capacity, space availability and your industry’s pallet-handling needs.

Different pallet inverter machines are designed for different applications. Businesses should evaluate the maximum weight and load sizes they handle daily. Space constraints matter, as some pallet inverters are freestanding while others are built-in. Industry-specific needs — such as handling fragile food products or pharmaceutical goods — may also dictate whether you need specific safety or sanitation features. By matching your pallet inverter equipment to your operational requirements, you ensure smoother workflows, safer handling and a better return on investment.