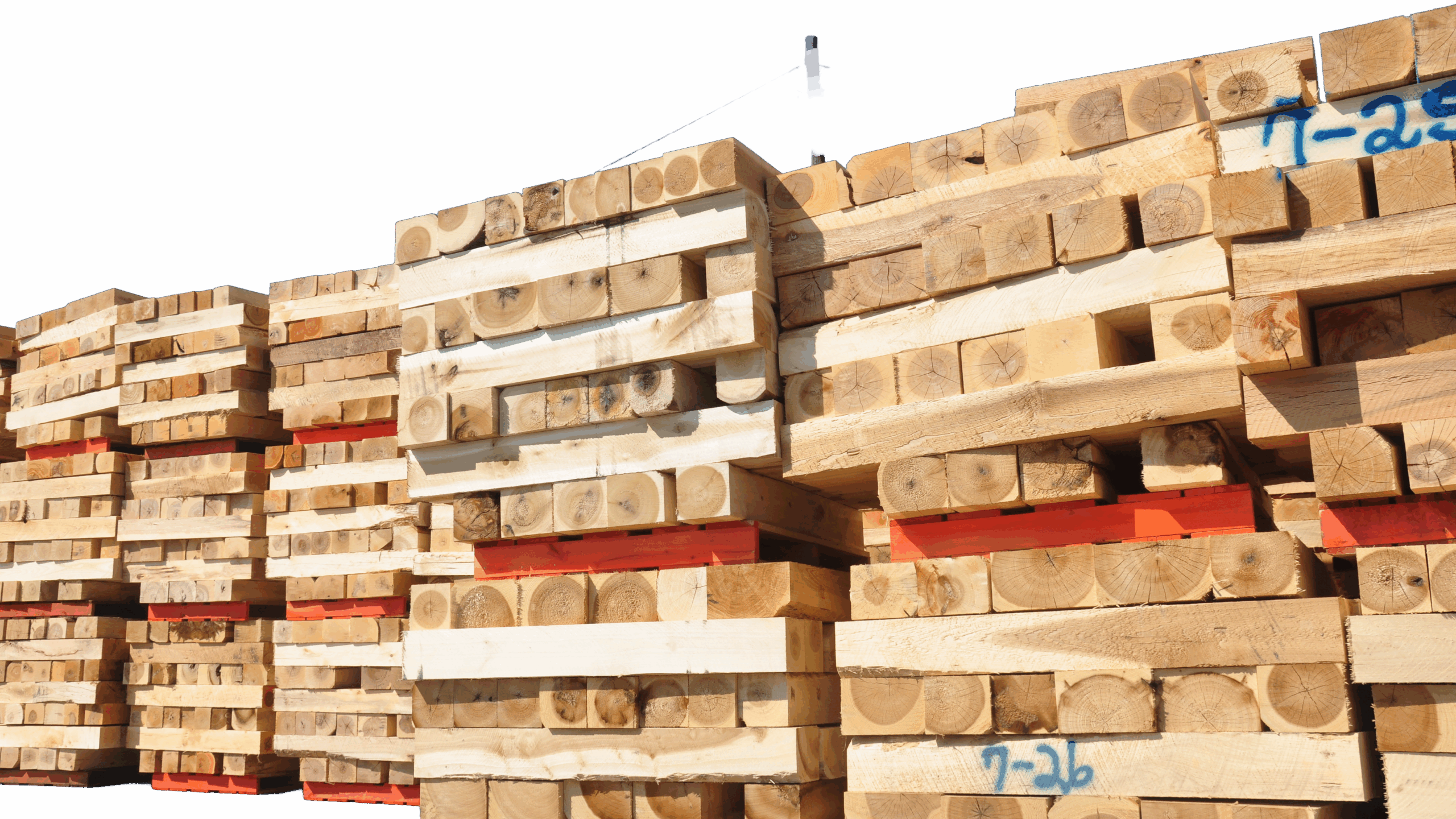

Pre Cut Pallet Lumber

Back to Lumber and Panels

Reliable Pre Cut Pallet Lumber for Efficient Manufacturing

Our pre cut pallet lumber is manufactured to exact specifications using hardwood, softwood logs, cants and kiln-dried lumber. By choosing pre cut pallet components, pallet manufacturers reduce waste, lower equipment costs and focus labor on building and shipping pallets rather than milling. This streamlined approach ensures higher yields, improved margins and a dependable pallet lumber supply.

Why Choose Pre cut Pallet Stock?

Cutting pallet parts in-house often requires expensive high-speed saws, dust collection systems and significant space for raw inventory. With pre cut pallet stock, manufacturers save on equipment maintenance, reduce disposal costs and eliminate inefficiencies. Each component arrives ready for assembly, ensuring consistency, productivity and cost savings.

Use Cases for Pre Cut Pallet Lumber

Pre cut components are ideal for pallet manufacturers of all sizes. Whether producing high volumes for export or fulfilling regional supply needs, companies benefit from uniform deck boards, stringers, and blocks in common sizes. Exporters can also order HT-stamped pieces, ensuring compliance with IPPC standards for international shipping.

Complex Packaging Needs? No Problem.

We know that no two applications are the same. That’s why we use our ISTA-certified Millwood Lab to test each end-of-line-packaging application against your exact load and handling requirements. Our approach avoids:

-

Under-engineering that can result in load failure and product damage

-

Worker safety hazards that may result in high employee turnover

-

Instead, we deliver a just-right solution—balanced for strength, cost and ease of operation

Why Choose Millwood as Your Solution Provider?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your lumber needs.

Steel, polyester and polypropylene strapping engineered for load containment. Works with tensioners and sealers to secure heavy or high-value goods.

Certified blocking and bracing solutions that keep shipments secure during transport.

Certified pallet heat treatment that eliminates pests and ensures compliance with global ISPM-15 regulations. Export-ready, chemical-free and eco-friendly.

Frequently Asked Questions

What is pre cut pallet lumber and why is it important for pallet manufacturers?

Pre cut pallet lumber refers to pallet components like deck boards, stringers and blocks that are cut to exact specifications. It helps manufacturers save time, reduce waste and improve margins by eliminating in-house cutting inefficiencies.

Pre cut pallet lumber provides a cost-effective solution for manufacturers that lack advanced sawing equipment or want to avoid maintaining a large raw material inventory. By outsourcing cutting, companies reduce overhead from machinery, labor and waste disposal. Pre cut components also improve consistency across production runs, which is vital for meeting customer requirements and international standards. Millwood’s solutions ensure reliable supply and custom sizing to help manufacturers focus on their core business: assembling and delivering pallets on time.

What are the advantages of buying pre cut pallet stock over cutting lumber in-house?

Purchasing pre cut pallet stock eliminates the need for expensive saws, dust collection systems and extra labor, while providing predictable, consistent pallet parts that lower overall production costs.

In-house cutting often requires specialized equipment like multi-trims or resaws, plus space and cash flow to carry raw material inventory. These hidden costs can significantly impact profit margins. With pre cut pallet stock, manufacturers save on capital investment, reduce waste hauling costs, and improve operational efficiency. The labor that would be tied to cutting components can instead be redirected toward building pallets. This streamlined approach supports faster turnaround times, higher quality output and stronger profitability, especially for facilities handling large volumes.

What types of wood are used in Millwood’s pre cut pallet lumber supply?

Millwood provides pre cut pallet lumber in hardwoods and softwoods, including green pine, green hardwood, kiln-dried heat-treated Southern Yellow Pine (SYP) and kiln-dried heat-treated SPF.

Each material type offers unique benefits. Green hardwood is durable and cost-effective, while green pine is versatile for stringers and deck boards. KD-HT SYP and SPF meet strict phytosanitary requirements, making them suitable for export pallets. Millwood ensures all pre cut lumber supply is processed to precise specifications, delivering consistent quality across every shipment. With a broad range of options, pallet manufacturers can select the right wood species for durability, compliance and budget requirements. This flexibility allows facilities to match their customers’ needs while avoiding costly errors.

Do pre cut pallet components need HT stamps for export compliance?

Yes. Each piece of pre cut pallet lumber must be individually HT stamped if the finished pallet is intended for international export and certified under IPPC standards.

The International Plant Protection Convention (IPPC) requires all wooden packaging materials used for export to be heat-treated and stamped to prevent the spread of pests. Even if a pallet is fully assembled in a certified facility, each component must carry the proper HT marking. Millwood supplies heat-treated and IPPC-compliant pre cut pallet stock, ensuring manufacturers can produce export-ready pallets without additional processing. By purchasing certified components, businesses save time, avoid compliance issues and confidently meet international shipping regulations.

What sizes and thicknesses are available in Millwood’s pre cut pallet stock?

Millwood offers a wide variety of sizes and thicknesses for deck boards, stringers and blocks, ensuring flexibility for both domestic and export pallet production.

For kiln-dried lumber, common deck board thicknesses include 7/16”, 11/16”, and 1.5” x 3.5” stringers. For green pine and hardwood, sizes range from 3/8” to 1” deck boards and 1” to 1.75” stringers. Block dimensions include 3.5” x 3.5” and 3.5” x 5.5”. This range allows manufacturers to meet custom design requirements while maintaining standardization. By purchasing pre cut pallet stock in these specifications, companies ensure accuracy, consistency and reduced waste across their operations. Millwood’s expertise guarantees components are cut precisely to match your production needs.