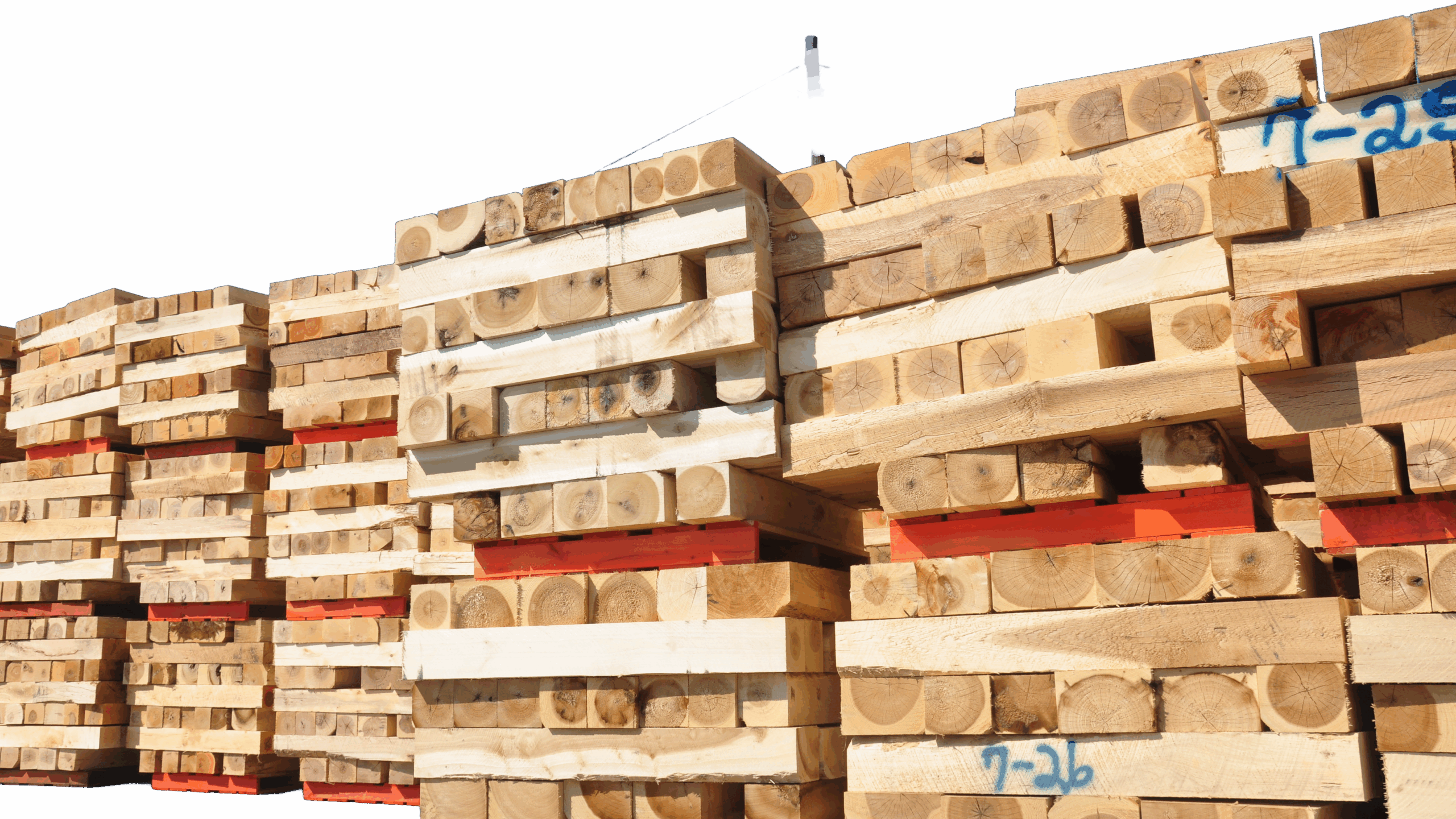

Cribbing Wood

Back to Lumber and Panels

Cribbing Wood for Stabilization and Heavy-Duty Support

Millwood provides cribbing wood designed to stabilize, elevate and support heavy equipment or structures during repair, construction or rescue operations. Our cribbing lumber is manufactured for strength, reliability and consistent performance in the most demanding environments.

Why Choose Wood Cribbing?

Cribbing blocks and lumber are essential for industries that require safe, temporary stabilization of large loads. Compared to alternative materials, wood cribbing delivers superior versatility and ease of handling, making it the preferred choice for heavy equipment service, mining and construction applications.

Use Cases for Cribbing Wood

Cribbing wood is widely used in equipment maintenance, construction projects, and urban search and rescue scenarios. It provides stable platforms for lifting, bracing and holding heavy objects securely. From elevating machinery to supporting structures in emergencies, cribbing blocks ensure dependable safety and functionality.

Material Quality Concerns? No Problem.

- Material failures that weaken pallets, crates or unit loads

- Inconsistent quality that slows production or increases rework

Instead, we deliver a just-right material solution—balanced for durability, cost and steady supply—so your packaging performs the way it should from the first board to the final shipment.

Why Choose Millwood as Your Solution Provider?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your lumber needs.

Steel, polyester and polypropylene strapping engineered for load containment. Works with tensioners and sealers to secure heavy or high-value goods.

Certified blocking and bracing solutions that keep shipments secure during transport.

Frequently Asked Questions

What is cribbing wood and how is it used?

Cribbing wood refers to stacked wooden supports, often arranged in an interlocking pattern, used to stabilize, elevate or secure heavy loads. It is commonly applied in construction, rescue operations and heavy equipment maintenance.

Cribbing wood, also called box cribs, is designed to provide safe, temporary structural support when machinery, vehicles or other large objects need to be lifted or stabilized. By using cribbing blocks and cribbing lumber in precise formations, industries like mining, construction and emergency response can create stable platforms under demanding conditions. Millwood manufactures durable wood cribbing designed to handle these applications with reliability and consistency, ensuring operators can safely perform repairs, maintenance or rescue activities.

What are the advantages of using cribbing blocks over alternative materials?

Cribbing blocks made from wood offer cost-effectiveness, easy handling and proven durability. They are lighter and more versatile than many synthetic alternatives, while still providing reliable support and stability for demanding applications.

Wood cribbing blocks interlock easily and can be stacked in multiple configurations, making them adaptable to a wide variety of uses. Unlike steel or plastic options, cribbing lumber is cost-efficient, readily available and field-tested across industries. Wood cribbing is also easier to transport and replace, reducing downtime. Millwood’s cribbing blocks are manufactured with quality standards that ensure long-term reliability, helping industries maintain safe working environments while keeping overall project costs manageable.

What industries rely most on cribbing wood?

Wood cribbing is widely used in construction, mining, heavy equipment service and emergency response. Its versatility allows it to provide temporary support and stabilization in a broad range of industrial and rescue applications.

Construction companies use cribbing lumber to stabilize structural components or heavy machinery. Mining operations employ cribbing wood to elevate or secure equipment underground. Heavy equipment service facilities rely on cribbing blocks for maintenance and repair. Urban search and rescue teams use wood cribbing in time-critical situations where stabilizing structures is essential to safety. Millwood supplies cribbing wood to meet these varied needs, ensuring high-quality solutions that adapt to multiple industries while maintaining safety and performance standards.

How strong and reliable is cribbing lumber for heavy loads?

Cribbing lumber is engineered to bear substantial weight when stacked properly. Its strength comes from high-quality wood and the stability of interlocking cribbing block configurations.

When arranged in a box crib pattern, wood cribbing can support massive loads while maintaining safety and stability. Proper stacking distributes weight evenly across the cribbing structure, preventing collapse under pressure. Millwood’s cribbing lumber is manufactured to meet industry demands, ensuring it delivers dependable performance in critical applications. Whether in construction, equipment repair or emergency scenarios, cribbing wood remains a trusted, proven solution for supporting and securing heavy objects efficiently.

What are common use cases for cribbing wood in field operations?

Cribbing wood is commonly used for heavy equipment repair, lifting machinery, stabilizing construction loads and providing support during rescue operations. Its versatility makes it essential across industrial and emergency service environments.

In practice, cribbing blocks are stacked beneath heavy vehicles or equipment to create safe elevation for inspection and repair. Construction crews rely on wood cribbing to brace beams or machinery temporarily. Mining operations use cribbing lumber underground where structural support is critical. Emergency responders, including fire and rescue teams, deploy cribbing wood to stabilize vehicles or collapsed structures. Millwood supplies cribbing solutions tailored to these scenarios, helping teams operate with efficiency, safety and confidence.