Value Added Solutions

Custom Wooden Crates for Every Shipping Challenge

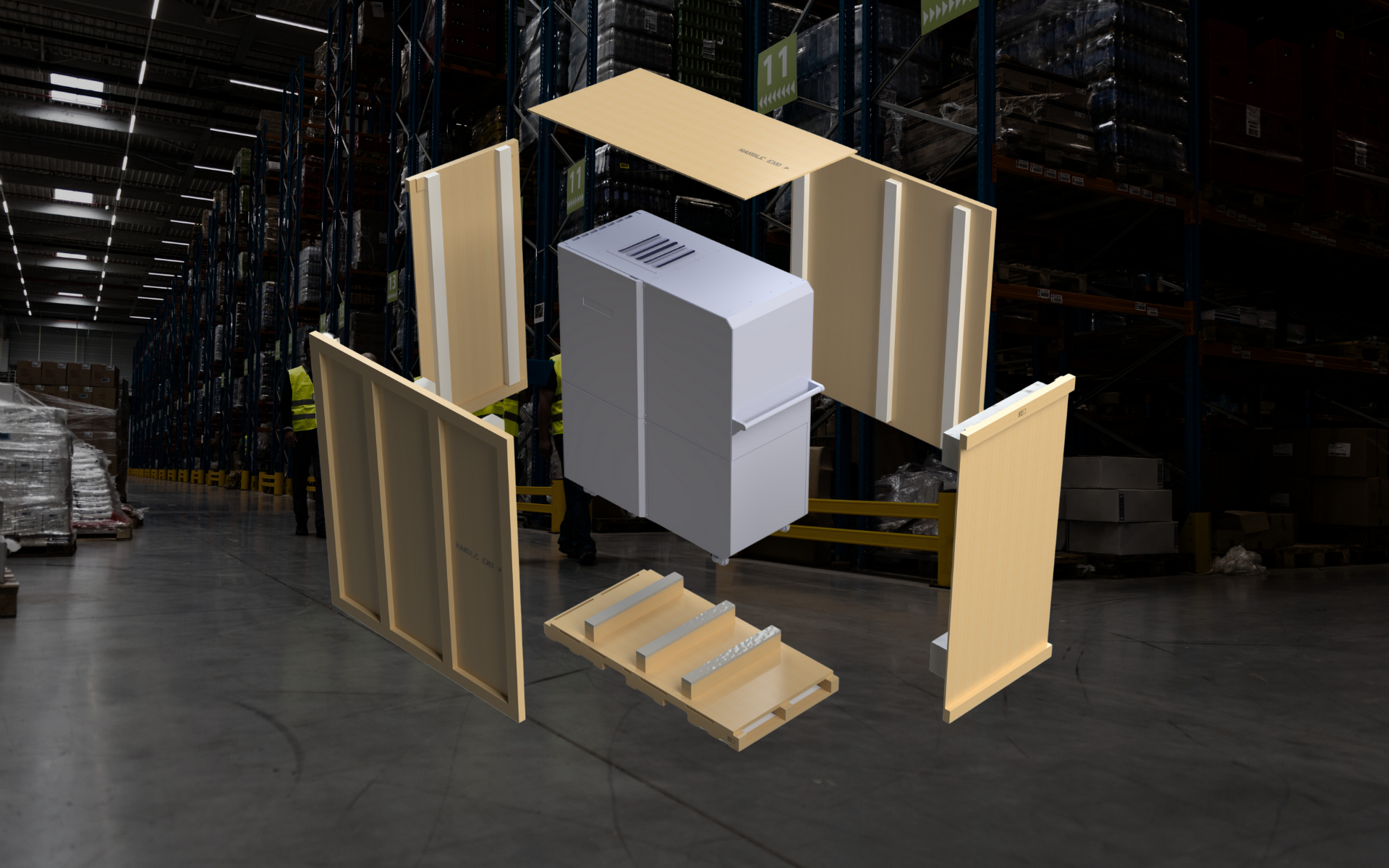

Lightweight custom wooden crates framed with lumber and corrugate panels, delivering cost-effective one-way or export crate solutions.

Convert standard pallets into reusable crates with hinged collars that collapse flat, reducing storage and return freight costs.

Our demo crates are engineered to deliver high-value equipment securely and repeatedly. From medical devices to industrial machinery, each crate provides the strength, precision and protection needed to ensure your product arrives ready for demonstration.

Protective custom wooden crates reinforced with foam, corrugate and standoffs, designed for sensitive or high-value industrial shipments.

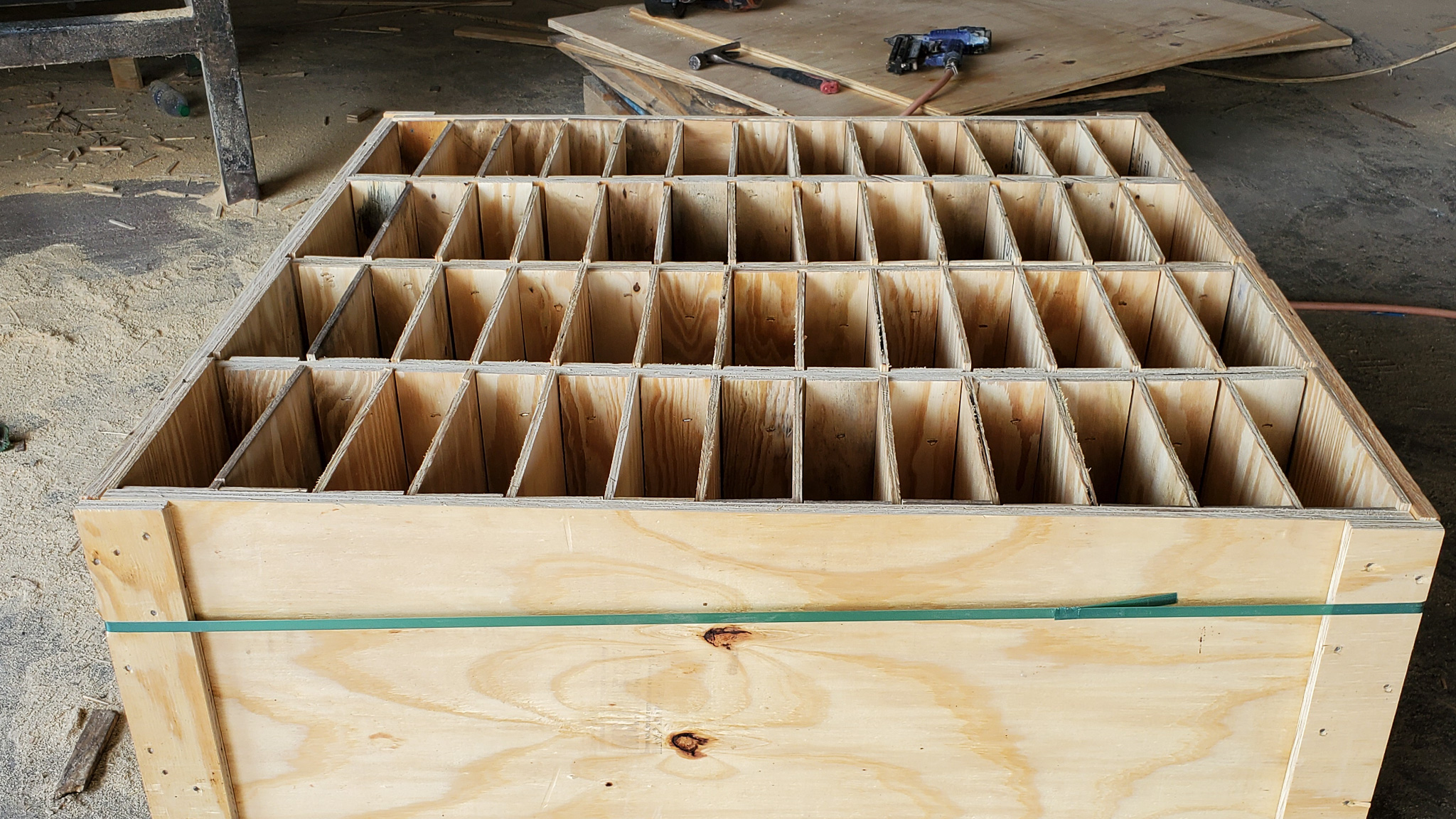

Durable wooden crate solutions with foam or rigid dividers, protecting sensitive components from part-to-part contact during shipment.

What Makes Millwood Different

Why Businesses Trust Millwood for Crating

-

On-Site Crating Capabilities – When products are too large or delicate to move, our teams can design and build crates at your facility.

-

Engineering Expertise – Every solution is backed by ISTA-certified testing and packaging science to reduce risk and optimize cost.

-

Responsive Design Team – 3D models and drawings delivered within 24–48 hours to keep projects moving.

-

Vertically Integrated Operations – From lumber sourcing to final assembly, Millwood controls every step for consistency and reliability.

-

Sustainability Commitment – Reusable designs, mold prevention and smart material use support efficiency without compromise.

Be SURE With Millwood

Study —

We begin by listening and learning your goals, challenges and pain points across facilities and vendors.

Understand / Engineer —

Our team designs and engineers solutions validated by packaging science and industry expertise.

Review / Verify —

Every solution is tested, certified and proven through lab validation and real-world trials before implementation.

Do You Have Questions?

Our Team Would Love to Connect and Listen.

Know What You’re Looking For?

Request A Quote.

Leveraging Our Experience to Serve You.

We understand that customers seeking industrial crating solutions need more than a box around their product — they need a trusted partner who can design, deliver and support crates built for real-world demands. Since 1985, Millwood has been a leader in wood pallets, and we bring that same expertise, reliability and vertical integration to our custom wooden crates. From oversized machinery to sensitive electronics, we engineer reusable crates, one-way options and hybrid designs to fit each application. Backed by our Packaging Science Lab, on-site crating capabilities, and decades of supply chain experience, Millwood supports every customer with proven solutions that protect products and streamline operations.

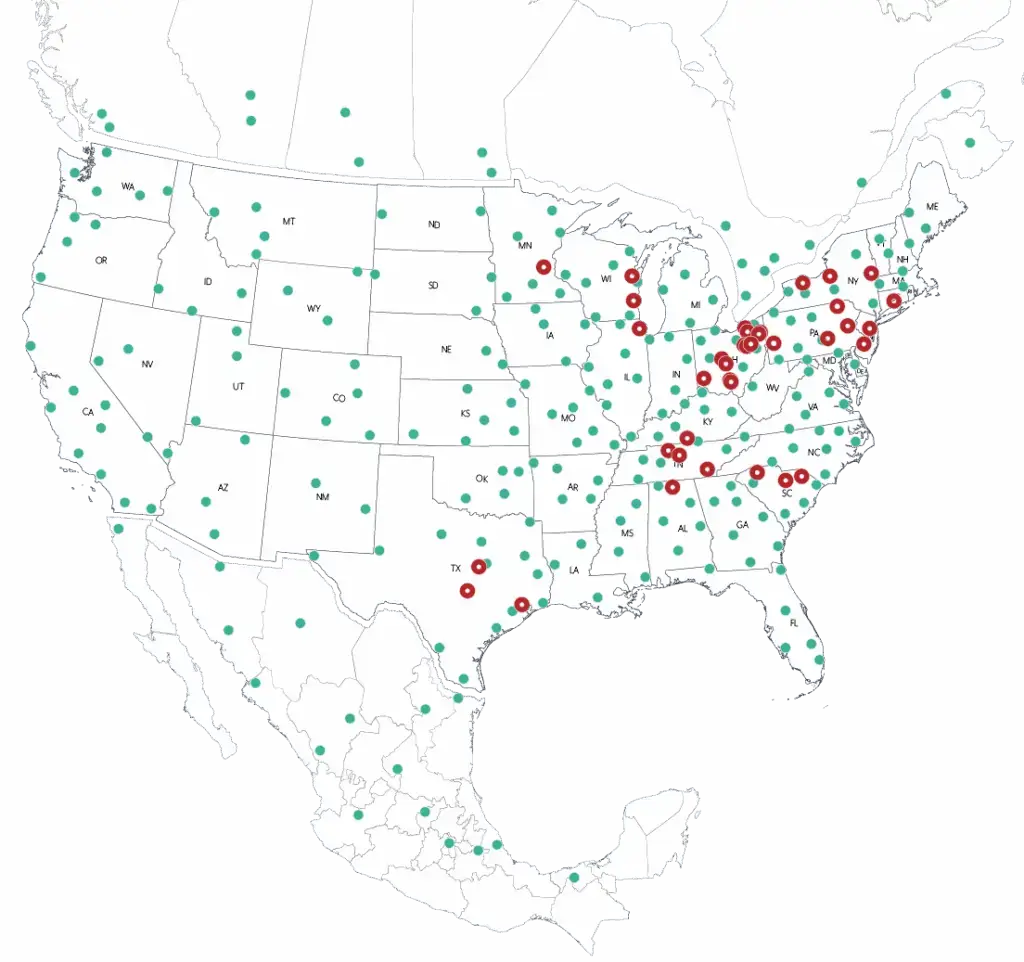

Source and Supply

With 37 strategically located manufacturing and repair facilities, 250+ strategic partners across North America and 1.5 million square feet of manufacturing and distribution space, Millwood controls its supply chain from the forest to the finished product. We handle more than 200,000,000 pallets and process over 100,000,000 board feet of lumber per year. Our vertically integrated operations ensure quality and reliable supply for our customers.

Exceptional Service

Serving others is our highest aim. Our dedicated customer support team delivers personal attention, not automated replies, with the care, integrity and expertise you deserve. We prioritize people by listening to your questions and concerns to provide the best support. When you connect with Millwood, you can expect an experience marked by professional care and genuine responsiveness. Trust us for consistent, customer-focused service that truly exceeds your expectations.

Sustainable

Operating under a culture of Perfect Stewardship, Millwood is committed to efficiency without compromise to our environment. From the way that our trees are harvested to our innovative line of sustainable packaging products and numerous recycling programs, we will work with you to reduce waste and meet your sustainability goals. Partner with us for sustainable solutions that support your business while protecting our planet.

Providing Comprehensive Solutions that Scale as Your Business Grows.

LET'S BUILD TOGETHER

Building strategically with Millwood means having a partner who can grow with you—no matter your size or goals. Whether you’re operating two locations or two hundred, choosing Millwood is a smart move because we are built for scale. We serve some of the nation’s largest brands and know how to support growth at every stage, from startups expanding rapidly to industry leaders adding facilities nationwide. That scalability ensures your packaging and pallet supply stays reliable and efficient as your business evolves.

We make scaling simple because we understand multi-location needs and service them with one integrated solution. Our nationwide reach and proven processes mean you don’t have to manage different suppliers for each region—we take care of it all. When time is critical and your business is growing fast, our ability to deliver consistently, at scale, across multiple facilities makes us a strategic partner you can count on.

Millwood is more than a pallet supplier—we’re a one-stop packaging solutions partner. From pallets to load securement, recycling solutions and strategic sourcing, we help optimize your supply chain and support your sustainability goals. Whether you buy 500 pallets a month or 5 million, we have the infrastructure, expertise and flexibility to scale with you. Partnering with Millwood means you gain a reliable ally who helps you focus on your growth while we handle your packaging needs.We would look forward to talking with you to see how we can help serve you.

As part of our Load Securement & Protection product line, Millwood’s Corner Protectors are designed to protect products from dents, strapping abrasions and shipping and handling damage.

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify and optimize designs to reduce product damage, minimize waste and improve supply chain efficiency.

PalletView

Track the quantity and condition of various managed assets such as pallets, tier sheets, plastic dunnage and airbags with PalletView, our proprietary web-based application.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

See How We've Helped Others

An industrial equipment manufacturer struggled with crate-related injuries, transit damage and poor visibility on job sites. Their off-the-shelf crates caused pinching hazards, lacked durability and made it difficult to track mission-critical components during installation.

By collaborating directly with plant managers, we designed a custom crate that solved all three problems. Thicker panels improved strength, a new latch system enhanced safety and stenciled branding increased visibility — transforming inefficiency into confidence.

- Increased panel thickness by 100% for greater durability and protection

- Eliminated worker injuries through a safer latch and ergonomic design

- Improved visibility and workflow with branded, easy-to-identify crates

Reliable. Available. Local.

We understand it is important to know that your pallets will be delivered on time, every time. That's why we are where you are.

Frequently Asked Questions

Millwood offers 13 different crate styles, from heavy-duty industrial shipping crates to lightweight one-way options. The best choice depends on your product’s size, weight, fragility and shipping environment.

Selecting the right crate is about more than dimensions — it’s about ensuring protection, efficiency and compliance. Heavy machinery may require reinforced oversized crates, while lightweight goods often ship in wire bound or hybrid corrugated options. Multi-component shipments benefit from divider crates, and fragile glass or stone moves best in A-frame designs. Millwood engineers each solution to your specifications and validates performance in our ISTA-certified lab. This consultative approach ensures you receive a “just-right” crate — never over-engineered or under-engineered — that balances cost savings with reliable protection across your supply chain.

Yes. Millwood offers nationwide on-site crating services when products are too large or sensitive to move to one of our facilities.

On-site crating is especially valuable for aerospace, defense, industrial machinery and construction equipment manufacturers. When items can’t leave the plant floor or installation site, our engineers bring the solution to you. Using SolidWorks design software and field-tested methods, Millwood teams build and secure crates tailored to your load in real time. This approach reduces unnecessary handling, minimizes risk of damage and accelerates delivery timelines. Combined with our vertically integrated lumber supply and packaging science expertise, on-site crating ensures even the most complex products are protected from the start of their journey to the final destination.

One-way crates are designed for single shipments, while reusable crates withstand multiple trips and handling cycles. Millwood engineers both, depending on your supply chain requirements.

One-way crates — like hybrid corrugated or wire bound designs — reduce material costs and freight weight, making them ideal for export or single-use shipments. Reusable crates — including knockdown, front hinged or stringer vaults — are engineered with stronger bases, fasteners and hardware to endure repeated use. Choosing between the two depends on product value, frequency of shipping and sustainability goals. Millwood helps customers evaluate total cost of ownership to determine whether a one-way or reusable solution delivers the best balance of protection, efficiency and environmental responsibility.

Millwood designs and manufactures crates that meet ISPM-15 compliance, ensuring smooth international shipping without delays or fines.

All wood packaging materials used in our crates are heat-treated and stamped to comply with global phytosanitary regulations. This is critical for companies shipping aerospace, defense and industrial equipment worldwide. Millwood’s vertical integration allows us to manage treatment, stamping and certification in-house, guaranteeing traceability and compliance. Combined with our ISTA-certified testing lab, we ensure that every crate is not only export-compliant but also durable enough to withstand the rigors of long-haul transit and varying climates. This gives customers peace of mind that their shipments will arrive safely and without costly regulatory issues.

Every crate design is validated in our ISTA-certified Packaging Science Lab, which simulates real-world shipping and handling conditions.

Our lab uses vibration, compression and impact testing to confirm that each crate protects its contents as designed. This scientific validation eliminates the risk of over-engineering, which inflates cost and under-engineering, which causes damage. By modeling and testing crates in a controlled environment, Millwood ensures that solutions deliver consistent performance across industries and applications. Customers benefit from greater reliability, fewer product losses and lower overall supply chain costs. With Millwood, you can trust that your crating program is engineered with precision and verified through data-driven results.

Yes. We integrate foam, corrugate and other protective elements into wooden crates for advanced cushioning and vibration resistance.

Mixed material crates are designed for sensitive, high-value shipments such as aerospace equipment, medical devices or electronics. Foam linings absorb shock, corrugate panels reduce weight, and engineered standoffs stabilize wheeled or delicate units. This hybrid approach provides superior protection compared to wood alone, while also streamlining packing workflows. Instead of manually wrapping products with insulation, Millwood builds protection into the crate itself — saving time, reducing labor and ensuring consistent performance. Our engineers tailor every hybrid solution to your product geometry, ensuring sensitive equipment arrives safely and efficiently.