Mixed Materials Crates

Back to Value Added Solutions

Know What You're Looking For?

Need Help Designing Your Create?

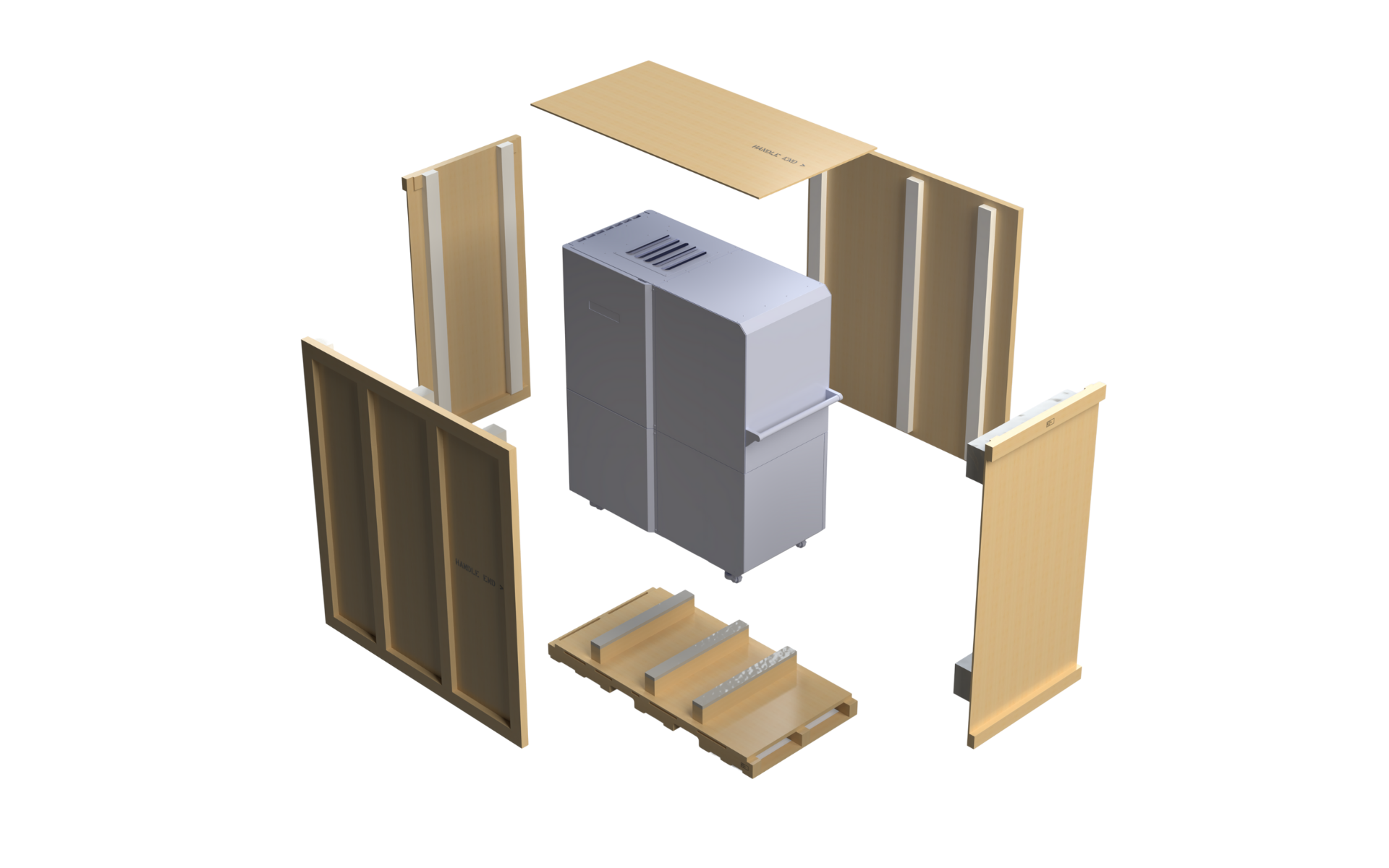

Custom Shipping Crates with Mixed Materials Protection

Our custom shipping crates go beyond traditional wood designs, integrating foam, corrugate and other materials for advanced cushioning and shock absorption. Built for sensitive, high-value equipment, each crate is engineered to minimize vibration and prevent costly damage in transit.

Engineered for Complex Loads

Every custom shipping crate is designed to your specifications. Mixed materials provide solutions for equipment with delicate surfaces, sensitive wheels or components that cannot shift or rest directly on the ground. From aerospace to medical devices, these crates safeguard precision equipment in demanding supply chains.

A Smarter Alternative to DIY Protection

Instead of strapping insulation or makeshift foam around your products, our crates feature integrated materials engineered to absorb impact. This reduces labor, speeds up packing and ensures consistent protection for every shipment.

Custom Requirements? No Problem

We know that no two applications are the same. That’s why we leverage our ISTA-certified Millwood Lab to engineer custom industrial crating solutions tailored to your exact load and handling requirements. Our approach avoids:

-

Over-engineering that drives up cost

-

Under-engineering that risks damage

-

Instead, we deliver just-right solutions backed by packaging science.

Why Choose Millwood As Your Crating Supplier?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of crating design and supply chain logistics.

-

Innovative Design & Testing: Our in house ISTA certified lab and custom design enable tailored, optimized crating solutions.

-

Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Crating Options

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their crating and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify and optimize designs to reduce product damage, minimize waste and improve supply chain efficiency.

Custom Design

Millwood guarantees full 3D modeling and drawings for every RFQ within 24-48 hours. Our design team will review your specifications to ensure that your custom engineered crating solution meets your application requirements, with our operations team ready to rapidly scale production capacity as needed.

Providing Supply Chain solutions

We’ve hand-picked these products to create a comprehensive solution that complements your crating needs.

Certified pallet heat treatment that eliminates pests and ensures compliance with global ISPM-15 regulations. Export-ready, chemical-free and eco-friendly.

Steel, polyester and polypropylene strapping engineered for load containment. Works with tensioners and sealers to secure heavy or high-value goods.

Hand and machine stretch wrap options that contain loads, prevent shifting and protect against dust and moisture with cost-efficient application.

Frequently Asked Questions

What are mixed materials custom shipping crates?

Mixed materials custom shipping crates combine wood with foam, corrugate or other protective elements to secure sensitive products. This hybrid approach provides cushioning, vibration resistance and stability beyond what standard wood crates can deliver.

A mixed materials custom shipping crate is designed to solve complex packaging challenges where wood alone is not enough. Foam lining absorbs vibration and impact during transit, corrugate panels reduce weight while maintaining strength, and integrated standoffs prevent wheeled units from rolling or sagging. These engineered crates are common in medical, aerospace, electronics and industrial applications where high-value items demand superior protection. By combining traditional durability with advanced materials, custom wood shipping crates become safer, faster to pack and more reliable for global supply chains.

Why choose a custom shipping crate with foam protection?

Foam-lined crates reduce the risk of shock, vibration and surface damage, making them ideal for transporting precision equipment. Integrated foam saves labor compared to manually wrapping products with insulation or padding.

When high-value equipment needs to travel, vibration and impact can cause expensive failures. A custom shipping crate with foam protection provides a built-in cushioning system that keeps products from shifting and protects delicate surfaces. Unlike DIY methods where foam sheets or insulation are taped or wrapped around a unit, these crates feature engineered foam placement along panels, standoffs, or floors. This creates a consistent, repeatable packing process that reduces labor time, increases efficiency and ensures every shipment arrives intact. For sensitive medical devices, lab instruments and heavy industrial units, foam integration in protective shipping crates is essential.

What industries use mixed material custom wood shipping crates?

Industries that ship high-value, sensitive or precision-built equipment often rely on mixed material custom wood shipping crates. Aerospace, healthcare, manufacturing and electronics all benefit from advanced cushioning and secure load stabilization.

Mixed materials provide tailored protection for industries where failure in transit is not an option. Aerospace companies use custom crates with foam to safeguard delicate avionics and instrumentation. Healthcare manufacturers ship imaging machines, surgical equipment and lab devices in engineered crates with vibration resistance. Industrial manufacturers rely on standoffs and reinforced panels to stabilize machinery during long hauls. Electronics producers use custom foam packaging crates to prevent movement and protect delicate circuitry. In each case, hybrid designs outperform standard crating, giving companies a smarter, safer way to deliver products to global customers without costly damage claims.

How are mixed materials crates different from standard custom crates?

Mixed materials crates differ by integrating foam, corrugate or engineered supports directly into the design, rather than relying solely on wood. This makes them more versatile and protective for complex shipping needs.

A standard custom crate is usually built entirely of wood. While durable, wood alone cannot always prevent vibration or surface damage for sensitive equipment. Mixed material custom shipping crates combine wood with specialized components to solve these challenges. Foam strips, corrugate reinforcements or standoffs provide enhanced protection against shock, movement or abrasion. This integrated approach removes the need for extra packing labor, reduces weight in some designs and ensures repeatable performance shipment after shipment. For companies seeking industrial crating solutions that balance strength with advanced protection, hybrid construction is the preferred choice over traditional wood-only crates.

What makes protective shipping crates more reliable for sensitive products?

Protective shipping crates are engineered with built-in cushioning, stabilizers or reinforcements that minimize transit damage. They go beyond standard crating by focusing on vibration control, impact absorption and secure load stabilization.

Unlike basic wood crates, protective shipping crates are specifically designed to safeguard delicate, high-value items against the harsh realities of transportation. They may include foam linings to absorb shock, corrugate layers to reduce weight or engineered standoffs to keep equipment elevated. This approach is ideal for industries where product integrity is critical, such as aerospace, medical and advanced manufacturing. By addressing both structural strength and protective performance, these crates reduce costly damage claims, extend product life and streamline packaging workflows. Businesses benefit from fewer failures in transit and greater confidence in their supply chain.

How do custom foam packaging crates improve shipping efficiency?

Custom foam packaging crates simplify the packing process while protecting sensitive surfaces. Foam is integrated into the crate’s design, reducing the need for manual wrapping and speeding up load-out times.

Traditionally, companies wrap products with insulation foam or padding before loading them into wood crates. This adds labor, time and inconsistency to the shipping process. Custom foam packaging crates eliminate that step by building foam directly into crate walls, standoffs or platforms. This ensures precision placement, vibration absorption and repeatable performance on every shipment. For products with delicate finishes, wheels or handles, integrated foam keeps surfaces from contacting wood panels or shifting in transit. Beyond protection, these engineered crates reduce packing labor, eliminate excess materials and improve throughput on busy shipping lines — all while maintaining the durability of custom wood shipping crates.