Hybrid Wood Corrugated Crates

Back to Value Added Solutions

Know What You're Looking For?

Need Help Designing Your Create?

Corrugated Crates & Hybrid Designs for Cost-Effective Shipping

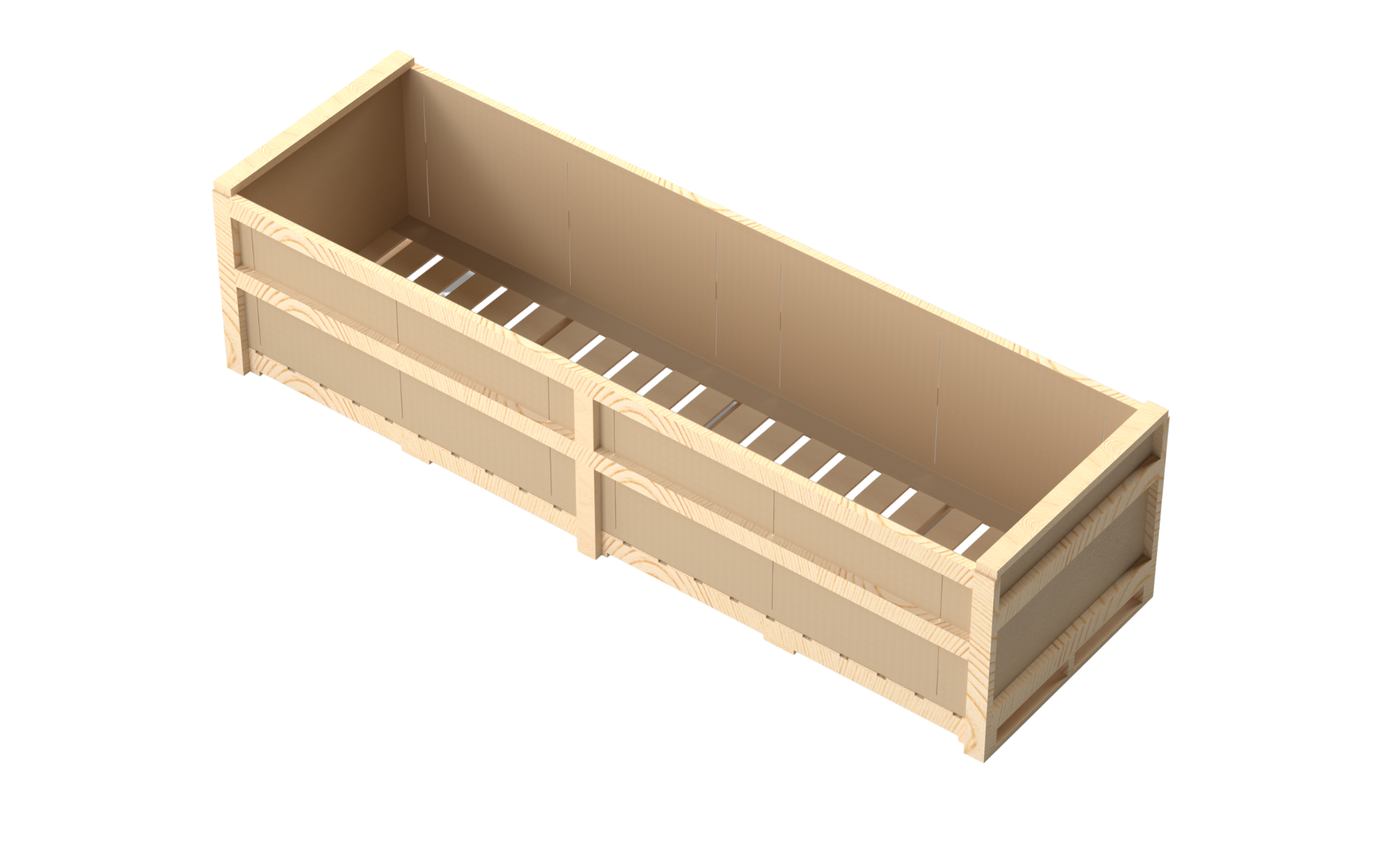

Millwood’s corrugated crates with wood framing deliver the best of both worlds: the strength of a lumber framework and the efficiency of corrugated walls. This hybrid design creates a low cost crate solution that is durable, lightweight and ideal for one way crate applications where budget and freight savings are essential.

HYBRID STRENGTH FOR EFFICIENT SHIPPING

Each corrugated crate starts with a traditional pallet base and a custom-fit lumber skeleton. Corrugated panels are then secured to the frame, forming a protective wall system that is significantly lighter than plywood or full-lumber builds. The result is a strong, versatile hybrid crate that balances durability with material and freight savings.

BEST USES FOR CORRUGATED CRATES

Corrugated crates are best suited for large, durable products such as rotomolded plastics or equipment that doesn’t require maximum wall strength. They are most often used as a one way crate for exports, disaster recovery storage, or short-term round trips where cost efficiency and weight reduction matter most.

Custom Requirements? No Problem

We know that no two applications are the same. That’s why we leverage our ISTA-certified Millwood Lab to engineer custom industrial crating solutions tailored to your exact load and handling requirements. Our approach avoids:

-

Over-engineering that drives up cost

-

Under-engineering that risks damage

-

Instead, we deliver just-right solutions backed by packaging science.

Why Choose Millwood As Your Crating Supplier?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of crating design and supply chain logistics.

-

Innovative Design & Testing: Our in house ISTA certified lab and custom design enable tailored, optimized crating solutions.

-

Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Crating Options

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their crating and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify and optimize designs to reduce product damage, minimize waste and improve supply chain efficiency.

Custom Design

Millwood guarantees full 3D modeling and drawings for every RFQ within 24-48 hours. Our design team will review your specifications to ensure that your custom engineered crating solution meets your application requirements, with our operations team ready to rapidly scale production capacity as needed.

Providing Supply Chain solutions

We’ve hand-picked these products to create a comprehensive solution that complements your crating needs.

Certified pallet heat treatment that eliminates pests and ensures compliance with global ISPM-15 regulations. Export-ready, chemical-free and eco-friendly.

Steel, polyester and polypropylene strapping engineered for load containment. Works with tensioners and sealers to secure heavy or high-value goods.

Hand and machine stretch wrap options that contain loads, prevent shifting and protect against dust and moisture with cost-efficient application.

Frequently Asked Questions

What makes hybrid corrugated crates different from standard wood crates?

Hybrid corrugated crates combine a lumber frame with corrugated walls, creating a lighter and more cost-effective alternative to all-wood builds. They balance strength and efficiency, making them a smart low cost crate solution.

These crates start with a pallet base and a wood skeleton, then add corrugated panels as protective sides. The hybrid design reduces material weight without compromising durability. Customers save on both lumber usage and freight costs, while still gaining the structural benefits of wood framing. This makes them ideal for cost-sensitive applications where efficiency and protection are both priorities.

When should I choose a hybrid corrugated crate over plywood or full-lumber designs?

Hybrid corrugated crates are best for large, durable items where freight savings matter more than maximum wall strength. They’re especially effective as a one way crate for exports or short-term shipping programs.

Plywood and lumber crates are still preferred for fragile, high-value products that require reinforced walls. But for items like molded plastics, equipment or disaster recovery storage, corrugated crates provide excellent protection with significantly lower weight and cost. Choosing them strategically helps optimize budgets without sacrificing safety in transit.

Are corrugated crates strong enough for one way shipments?

Yes, properly engineered hybrid corrugated crates are durable enough for one way shipments. Their wood framework provides structural strength, while corrugated panels cut weight and costs.

Millwood engineers each crate to meet the exact product and handling requirements. With ISTA-certified testing, designs are validated against real shipping conditions to ensure protection. While not intended for repeated long-term use, these crates reliably handle single-trip or short-cycle logistics, particularly for products that don’t demand heavy reinforced walls.

How much can businesses save by using a low cost crate design?

Switching to hybrid corrugated crates reduces material and freight costs by lowering lumber usage and overall shipping weight. Savings typically scale with shipment volume and freight distance.

Because corrugated panels are lighter than plywood, customers often see substantial reductions in freight bills, especially for exports and air shipments. Material costs are also reduced since less lumber is required. Combined, these savings allow businesses to reallocate budgets toward other supply chain priorities, all while maintaining reliable shipping protection.

Can hybrid corrugated crates be customized for different products?

Yes, each corrugated crate is engineered to match product size, weight and handling needs. Options include wall thickness, reinforced frames, and custom pallet bases.

Millwood’s design team provides 3D models within 24–48 hours of RFQ submission, ensuring specifications are validated early. Customers can choose between single-wall or triple-wall corrugate, reinforced frameworks for heavier loads, and tailored footprints for unique equipment. This ensures every hybrid crate is optimized for protection, cost efficiency and ease of handling across varied industries.