Stringer Vault Industrial Storage Crates

Back to Wooden Crates

Know What You're Looking For?

Need Help Designing Your Create?

Stringer Vault Crates – Secure and Durable Storage

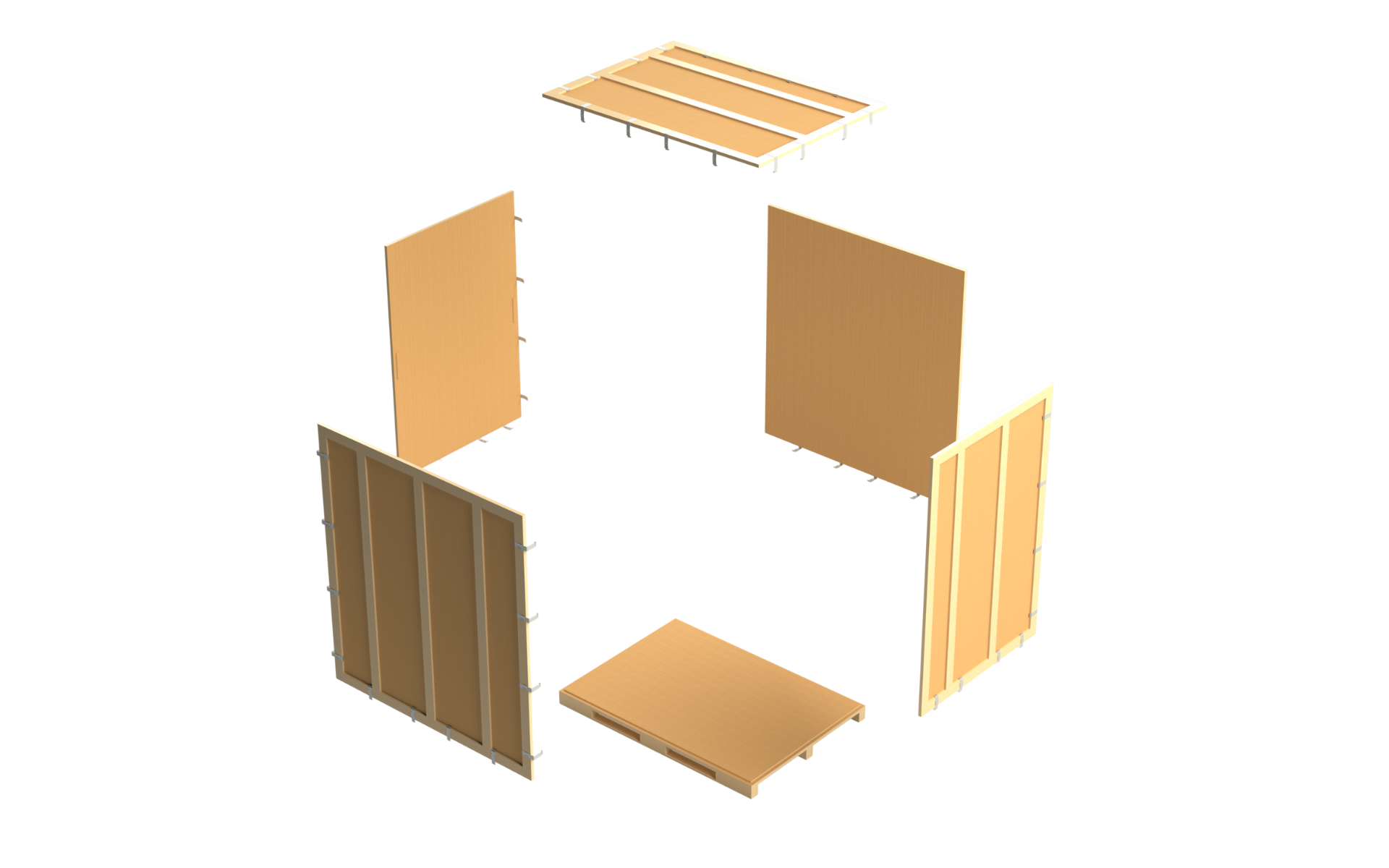

Stringer vault crates, often called clipped vaults, are heavy-duty, reusable storage solutions built for protecting and organizing valuable contents during restoration, relocation or extended storage. As industrial storage crates, they feature strong stringer construction and a proven design trusted by the disaster recovery industry to keep belongings safe until they’re ready to be returned.

Purpose Built for Disaster Recovery

Popular among restoration and remediation companies, stringer vault crates are ideal for securely storing furniture, personal belongings and equipment after events like fires, floods or major renovations. Their robust build keeps contents protected in a warehouse environment until restoration is complete. This durability makes them one of the most dependable industrial storage crates available for safeguarding valuables until they can be delivered back to customers.

Reusable, Durable and Versatile

While they’re best known as disaster recovery crates, stringer vault crates work in any industry that requires dependable, long-term storage. Their strong stringer pallet base provides stability for stacking and transport, while the enclosed walls keep contents shielded from dust and debris. Designed for reuse, these vaults deliver lasting value over multiple projects.

Custom Requirements? No Problem

We know that no two applications are the same. That’s why we leverage our ISTA-certified Millwood Lab to engineer custom industrial crating solutions tailored to your exact load and handling requirements. Our approach avoids:

-

Over-engineering that drives up cost

-

Under-engineering that risks damage

-

Instead, we deliver just-right solutions backed by packaging science.

Why Choose Millwood As Your Crating Supplier?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of crating design and supply chain logistics.

-

Innovative Design & Testing: Our in house ISTA certified lab and custom design enable tailored, optimized crating solutions.

-

Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Crating Options

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their crating and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify and optimize designs to reduce product damage, minimize waste and improve supply chain efficiency.

Custom Design

Millwood guarantees full 3D modeling and drawings for every RFQ within 24-48 hours. Our design team will review your specifications to ensure that your custom engineered crating solution meets your application requirements, with our operations team ready to rapidly scale production capacity as needed.

Providing Supply Chain solutions

We’ve hand-picked these products to create a comprehensive solution that complements your crating needs.

Certified pallet heat treatment that eliminates pests and ensures compliance with global ISPM-15 regulations. Export-ready, chemical-free and eco-friendly.

Steel, polyester and polypropylene strapping engineered for load containment. Works with tensioners and sealers to secure heavy or high-value goods.

Hand and machine stretch wrap options that contain loads, prevent shifting and protect against dust and moisture with cost-efficient application.

Frequently Asked Questions

What are industrial storage crates used for?

Industrial storage crates protect large, high-value items during shipping and long-term storage. They are engineered for strength, stability and compliance, reducing the risk of costly damage in demanding supply chains.

Industrial storage crates are designed for companies handling heavy or fragile products that must remain secure throughout transportation or warehouse storage. Built from reinforced wood, they provide durability against impacts, stacking stress and environmental conditions. Manufacturers in aerospace, defense and heavy equipment industries rely on vault crate and industrial storage crate solutions to protect engines, compressors and sensitive tooling. Millwood engineers each crate to product specifications, ensuring optimal load stability, moisture resistance and export compliance to safeguard assets and reduce operational risk.

How is a vault crate different from a standard industrial storage crate?

A vault crate is a reinforced industrial storage crate with heavier framing and added protection for oversized or sensitive equipment.

Unlike standard crates, a vault crate features thicker walls, stronger bracing and enhanced construction to manage extreme weights or complex product geometries. These reinforced wooden crates are ideal for long-term storage or international shipments where load integrity is non-negotiable. Aerospace and defense companies use vault crates to protect high-value assemblies, while industrial manufacturers rely on them to secure compressors, motors, or tools. Millwood designs vault crate solutions with packaging science expertise, ensuring that each crate meets handling, stacking and compliance requirements while delivering maximum durability and product safety.

Which industries benefit most from industrial storage crates?

Industries like aerospace, defense, heavy machinery and automotive rely heavily on industrial storage crates to protect valuable shipments.

Industrial storage crates provide reliable protection for products too heavy, fragile or costly to risk damage. Aerospace and defense manufacturers ship avionics, assemblies, and sensitive components in vault crate solutions. Heavy machinery and equipment companies use industrial storage crates for pumps, motors and oversized assemblies. Automotive suppliers rely on reinforced wooden crates to move tooling and precision-engineered parts securely. Each application benefits from Millwood’s engineering expertise, which tailors every crate to product size, weight and environmental demands. By combining durability with compliance, Millwood ensures products arrive safely while optimizing cost efficiency across supply chains.

Can industrial storage crates be customized?

Yes — industrial storage crates can be engineered with reinforcements, foam, blocking and bracing to fit unique product needs.

Every shipment carries different requirements, and customization is central to effective crate design. Millwood engineers vault crate and industrial storage crate solutions using specifications such as weight, fragility and export regulations. Options include reinforced wooden crate construction, moisture barriers, shock-absorbing foam and ISPM-15 heat treatment for global compliance. Knock-down clip crates allow easier handling and storage flexibility. By validating designs in Millwood’s Packaging Science Lab, customers gain confidence that their crates meet load demands and shipping conditions. Customized industrial storage crates not only reduce the risk of damage but also streamline costs and protect brand reputation.

Are industrial storage crates suitable for export shipping?

Yes — industrial storage crates are built to meet ISPM-15 export compliance and withstand international transit conditions.

When products ship overseas, compliance and durability are critical. Millwood designs vault crates and industrial storage crate solutions to meet ISPM-15 standards through heat treatment, eliminating pests that delay or block shipments at customs. These reinforced wooden crates also withstand the rough handling and varied climates encountered in global transit. Heavy machinery, aerospace components and defense equipment often require this level of packaging reliability. Millwood’s nationwide network and Packaging Science Lab ensure each crate is tested, compliant and optimized for safe delivery worldwide, giving businesses peace of mind when shipping high-value products internationally.