Packaging Equipment Parts

Request a Quote

Thank you for reaching out about a quote from our team. Please complete the form below and one of our team members will be in touch with you. If you are currently or planning to use this product for multiple applications, please complete the form with the information from your largest load by total dimension. (LxWxH)

High-Quality Packaging Equipment Parts for Every System

Millwood, Inc. provides reliable packaging equipment parts, material handling parts and conveyor system parts designed to keep your operations running smoothly. From stretch wrappers to ergonomic lifting devices, our parts ensure optimal performance and longevity of your machinery.

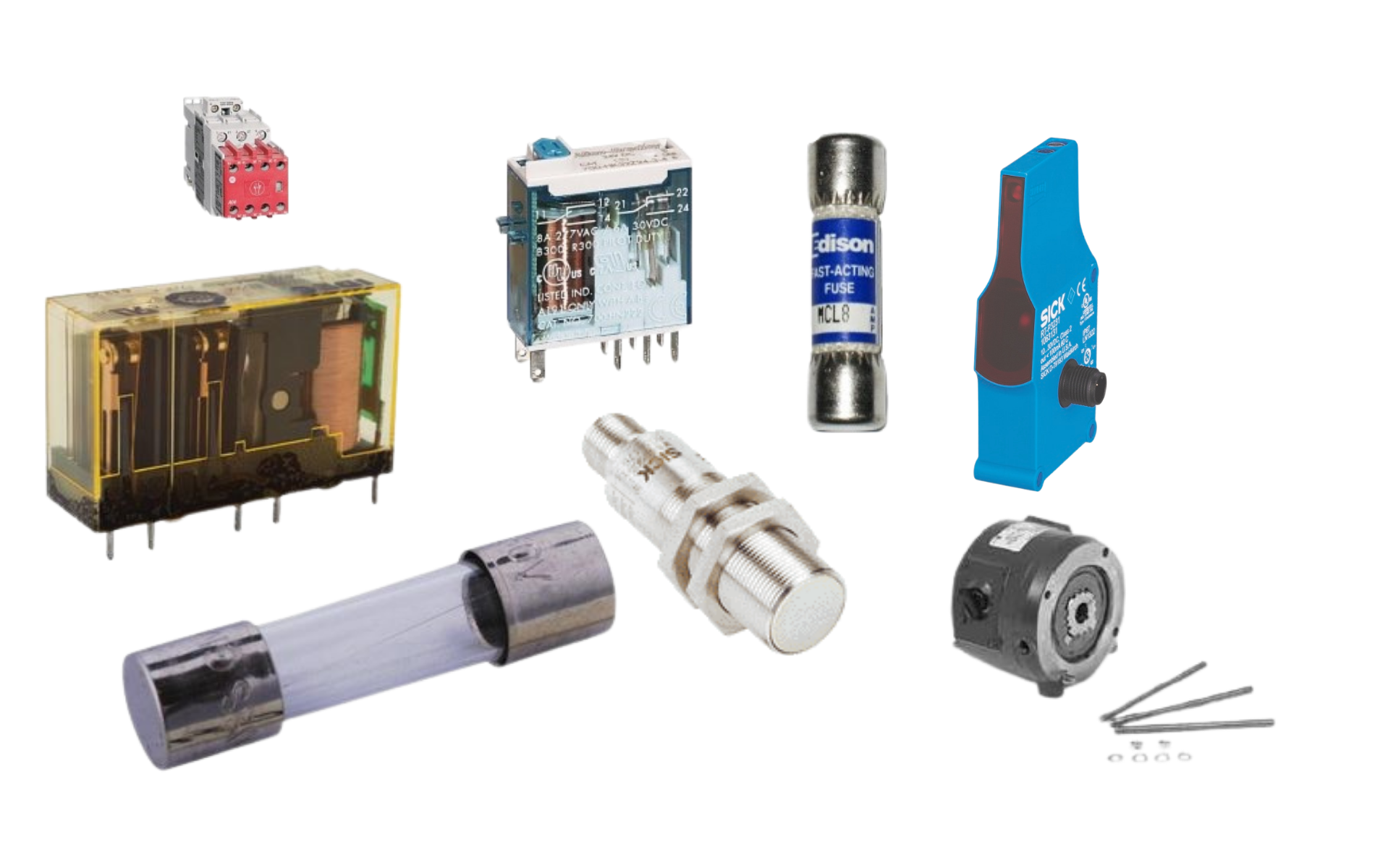

Extensive Selection of Replacement Parts

Our inventory includes packaging equipment parts, conveyor system parts and material handling parts for stretch wrappers, shrink systems, palletizers, strapping machines, robotic palletizing, taping systems and more. If a part isn’t in stock, our team will source it quickly to minimize downtime.

Seamless Integration with Ergonomic Equipment

Complement your packaging systems parts with ergonomic equipment designed for safety and efficiency. Lift, maneuver and package loads with ease while maintaining productivity across your material handling process.

Custom Requirements? No Problem.

- Under-engineering that can result in pallet failure and product damage

- Over-engineering that drives up unnecessary costs and excess freight weight

- Instead, we deliver a just-right solution—balanced for strength, cost, and performance

Why Choose Millwood as Your Solution Provider?

- Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

- Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

- Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Packaging Systems

We will work to understand the problems you are having and as a team to provide solutions.

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify, and optimize designs to reduce product damage, minimize waste, and improve supply chain efficiency.

System Maintenance

Millwood offers complete pallet recycling programs to retrieve, inspect, recover, and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your packaging needs.

High-strength tape for sealing cartons and reinforcing packages. Designed to withstand handling stress and secure shipments effectively.

New, recycled, pressed wood, corrugated, plastic, and alternative pallets for every industry. Discover the best solution for you.

Protect pallet edges from strapping abrasion, crushing and collapse. Available in Corner, Edge, Flex and Notch Defender options.

Frequently Asked Questions

What types of packaging equipment parts are available?

Packaging equipment parts include replacement belts, rollers, motors, sensors and other machine components. These parts ensure packaging systems continue to run reliably.

A wide range of replacement packaging machine parts are available, covering everything from conveyor belts and stretch wrapping rollers to electrical sensors and sealing units. Choosing the right components extends machine life, reduces costly downtime and helps operators avoid full equipment replacements. Industrial packaging machine parts can be sourced as OEM or aftermarket options, depending on whether you require exact manufacturer replacements or more cost-effective alternatives. Ensuring access to a trusted supplier for all parts helps keep your production schedules on track.

Why are OEM and aftermarket packaging parts important?

OEM packaging parts guarantee original fit, while aftermarket options offer cost savings without sacrificing quality or performance.

OEM (Original Equipment Manufacturer) packaging equipment parts are designed to match your exact machine specifications, ensuring seamless fit and reliable operation. However, aftermarket packaging parts provide a competitive alternative, often available faster and at lower cost. Businesses often mix both OEM and aftermarket options, depending on performance needs, availability and budget. Having a supplier who can source both ensures flexibility, resilience and cost-efficiency in your maintenance strategy, particularly when unexpected breakdowns occur in end-of-line packaging operations.

How do replacement parts reduce downtime in packaging operations?

Timely replacement packaging parts prevent breakdowns, keep machines efficient and avoid costly production stoppages.

Downtime in packaging lines can be one of the most expensive problems manufacturers face. Even a short stoppage due to a failed roller, broken belt or faulty sensor can result in missed deadlines and lost revenue. Replacement packaging machine parts ensure equipment continues to run smoothly and consistently. By keeping critical spares on hand and establishing a relationship with a reliable supplier, businesses can quickly replace worn or damaged components, minimizing disruptions. Preventative replacement also extends machine lifespan and helps avoid emergency repair costs.

What industries rely on packaging equipment replacement parts?

Packaging equipment parts are essential across food, beverage, industrial, pharmaceutical and e-commerce supply chains.

Every industry that depends on automated packaging machinery requires access to dependable replacement parts. Food and beverage manufacturers often rely on stretch wrapping and sealing machine parts, while industrial suppliers need palletizing and conveyor components. Pharmaceutical and chemical companies demand parts that meet strict compliance standards. E-commerce and retail distribution centers depend on high-speed equipment that can’t afford breakdowns. Packaging equipment parts suppliers must therefore support a wide range of industries, offering flexibility and custom-engineered solutions to match diverse operational demands.