Strapping

Back to Load Securement and Protection

Know What You're Looking For?

Need More Help With Your Load?

Strapping Solutions for Heavy-Duty & Sensitive Loads

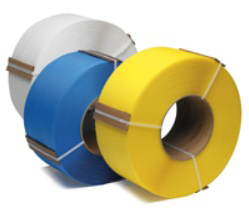

Our load securement strapping options—available in steel strapping and poly strapping—deliver reliable, industrial-grade protection for securing products during storage and transport. Whether you need maximum strength for heavy-duty pallets or gentle support for boxed goods, our industrial strapping solutions provide the right fit for your load requirements.

Choose the Right Strapping for Your Load

One of the most common questions we hear is: “What kind of strapping do I need?” The answer depends on your application. Steel strapping is designed for extremely heavy or rigid loads that require superior break strength. Poly strapping is better for lighter or more sensitive products, such as cartons or packages that could be crushed under the pressure of steel.

Built for Performance and Compliance

Our strapping can be applied with manual hand tools or fully automated machines, making it ideal for operations of any scale. For intermodal shipments, including rail transport, we also offer AAR-approved industrial strapping to ensure compliance with the Association of American Railroads’ standards. Options include multiple widths, thicknesses, colors and finishes (embossed or smooth) to match your exact needs.

Complex Packaging Needs? No Problem.

- Corner Defender – Reinforces 90° corners and prevents strapping abrasion.

- Edge Defender – Protects edges and strengthens unitization for better stability.

- Notch Defender – Provides durable corner and edge protection for heavy or high-impact loads.

Custom-made to order and 100% recyclable, the Defender Series delivers the protection, strength, and peace of mind your supply chain demands—because at Millwood, we’ve got every corner covered.

Why Choose Millwood As Your Single Source Provider?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Strapping

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify, and optimize designs to reduce product damage, minimize waste, and improve supply chain efficiency.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your damage prevention needs.

Frequently Asked Questions

What is strapping used for?

Strapping is used to secure products within their pallet, crate or other load securement vessel for safe storage, handling and shipping, reducing the risk of shifting or product damage during transport.

Millwood’s strapping options deliver reliable protection by stabilizing heavy-duty and sensitive loads. Steel strapping provides unmatched break strength for rigid or sharp-edged products, while poly strapping delivers secure yet flexible support for cartons, boxed goods or delicate items. Both types keep your loads secure throughout warehousing and logistics processes, ensuring shipments arrive without costly damage or product loss. Whether applied with hand tools or automated machines, strapping is a critical element of load securement that supports efficient supply chain operations and reduces the risk of packaging failure.

When should I choose steel strapping over poly strapping?

Steel strapping is best for heavy, rigid loads, while poly strapping works better for lighter or more delicate cartons that could be crushed under higher tension.

Steel strapping offers maximum break strength, making it ideal for industries handling industrial machinery, building materials or dense pallets requiring superior stability. Polypropylene and polyester strapping, by contrast, are safer for packaging lighter loads, offering flexibility without risking carton damage. Millwood provides a range of widths, thicknesses and finishes to match unique product demands. Choosing the right option ensures you balance safety, performance and cost efficiency, preventing both under-engineering that risks load failure and over-engineering that adds unnecessary expense to packaging operations.

Is strapping approved for rail or intermodal shipping?

Yes—Millwood offers AAR-approved strapping that meets Association of American Railroads standards for intermodal and rail transport compliance.

AAR-approved strapping is engineered to withstand the vibrations, impacts and stresses associated with long-distance freight shipments. This makes it the trusted solution for intermodal loads moving by rail, truck and sea. Millwood provides both steel and poly options that meet compliance requirements while delivering consistent break strength and load security. By choosing certified strapping, shippers ensure safe handling across multiple modes of transportation, reduce liability risks and maintain compliance with industry standards. This helps businesses protect their cargo while optimizing logistics for complex, multi-stage shipping routes.

How does strapping improve load safety?

Our strapping enhances load safety by securing goods and preventing them from shifting, separating or collapsing during handling, transit or storage.

Properly applied strapping distributes pressure evenly, keeping cartons, crates or irregular loads locked securely in place. Steel strapping delivers unmatched strength for dense or sharp-edged goods, while poly strapping offers gentler containment for fragile or crushable products. Millwood’s strapping solutions integrate seamlessly with manual tools and automated machines, providing flexibility for operations of all sizes. By reducing load movement and damage risk, strapping not only protects products but also helps companies lower costs related to claims, rework and product loss. It is an essential safeguard for supply chain stability.

Why choose Millwood strapping solutions?

Millwood strapping solutions combine strength, compliance and customization, backed by decades of packaging expertise and ISTA-certified testing.

Millwood provides both steel and poly strapping in multiple widths, thicknesses, colors and finishes—ensuring customers get the right match for their load type and shipping conditions. AAR-approved options make compliance straightforward for intermodal shippers. Each strapping solution is designed to provide consistent protection while integrating into existing packaging workflows. With industry-leading testing, customer-focused support and a commitment to sustainability, Millwood delivers strapping that balances performance and cost efficiency. Choosing Millwood means gaining a trusted partner in packaging securement, protecting products across every stage of the supply chain.