Shrink Film

Back to Load Securement and Protection

Know What You're Looking For?

Need More Help With Your Load?

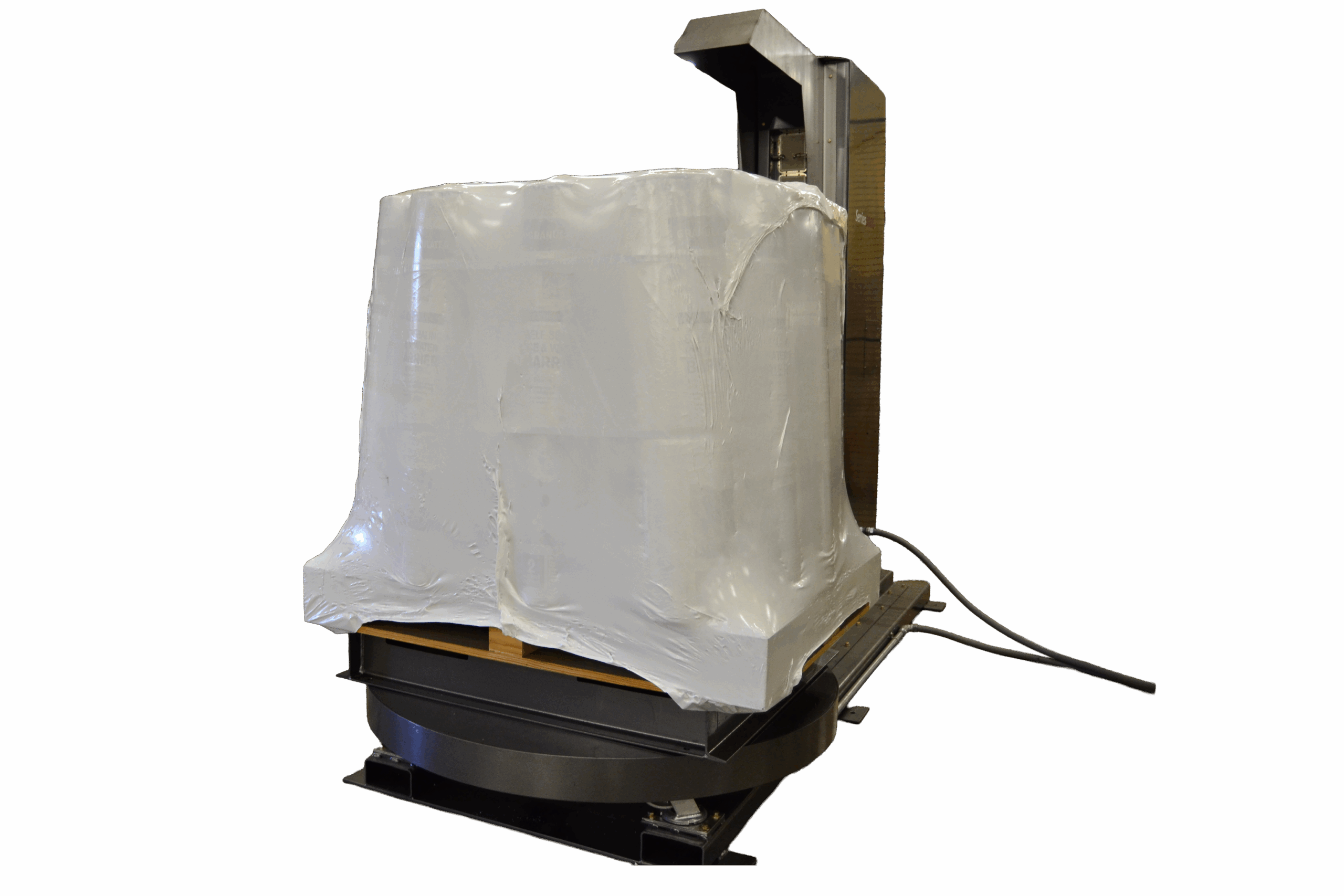

Shrink Film for Maximum Pallet Protection

Millwood’s shrink film delivers durable five-sided coverage for pallets, offering superior protection against dust, dirt and moisture. Ideal for heavy or outdoor-stored loads like shingles and rolled roofing, pallet shrink wrap ensures your products stay secure, uniform and tamper evident.

Strong, Reliable Pallet Shrink Wrap

Compared to stretch film, pallet shrink wrap requires heat application and may cost more upfront, but its efficiency and space-saving advantages make it an economical long-term choice. Shrink wrap film is perfect for applications where neatness, protection and floor space optimization matter.

Industrial Strength, Flexible Application

Made from durable polymer plastic film, shrink wrap film adapts to any pallet size or shape. Once heated, it conforms tightly to the load, ensuring secure unitization and simplified storage.

Complex Packaging Needs? No Problem.

- Corner Defender – Reinforces 90° corners and prevents strapping abrasion.

- Edge Defender – Protects edges and strengthens unitization for better stability.

- Notch Defender – Provides durable corner and edge protection for heavy or high-impact loads.

Custom-made to order and 100% recyclable, the Defender Series delivers the protection, strength, and peace of mind your supply chain demands—because at Millwood, we’ve got every corner covered.

Why Choose Millwood As Your Single Source Provider?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Shrink Film

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify, and optimize designs to reduce product damage, minimize waste, and improve supply chain efficiency.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your damage prevention needs.

Frequently Asked Questions

What is shrink film and why is it used for pallet protection?

Shrink film is a polymer-based wrap that provides five-sided coverage, protecting pallets from dust, dirt, moisture and tampering. It’s ideal for heavy, outdoor-stored or uniform loads that need secure unitization and long-term stability.

Shrink film works by being applied over a pallet load and heated, causing it to conform tightly to the shape of the products. This creates a durable, tamper-evident seal that maintains product integrity during storage and shipping. Unlike stretch film, pallet shrink wrap requires heat application, but it offers added strength, space savings and uniform load security. It’s widely used in industries like construction, roofing, and manufacturing.

How does pallet shrink wrap compare to stretch film?

Pallet shrink wrap provides stronger load unitization and better environmental protection than stretch film, but requires heat application and may cost more upfront. Its advantages include tamper evidence, durability and long-term efficiency for industrial applications.

While stretch film is quicker and less expensive to apply, pallet shrink wrap offers superior coverage, protecting loads from dirt, dust and weather exposure. Shrink wrap film is particularly beneficial for heavy or outdoor-stored pallets, such as shingles, roofing rolls or bagged products. The heat-sealed material ensures that the load remains neat, stable and space efficient. This makes shrink film the more economical choice when protection and durability outweigh short-term cost.

What industries benefit most from shrink wrap film?

Industries with heavy, bulky or outdoor-stored goods benefit most from shrink wrap film. Construction, roofing, manufacturing and distribution companies often use it to ensure load security and protection against environmental elements.

Because shrink wrap film creates a tamper-evident, uniform seal, it’s widely chosen by businesses that require consistent packaging and load unitization. Roofing materials like shingles, rolled roofing and bagged building supplies are excellent use cases. Manufacturers also rely on pallet shrink wrap for items needing long-term storage or transport protection. Millwood provides industrial-grade shrink film solutions tailored to these industries, ensuring pallets are secure, protected and easier to handle across different storage environments.

Is shrink film tamper-evident and secure for shipping?

Yes. Shrink film provides a tamper-evident seal that clearly shows if packaging has been opened or altered. This added security makes it a reliable choice for sensitive or high-value shipments across multiple industries.

Once heat is applied, pallet shrink wrap tightly conforms to the shape of the load. This seal cannot be removed without leaving obvious signs of tampering. Shrink wrap film also provides durability and stability during shipping, protecting goods from shifting or being contaminated by dirt and dust. For industries that prioritize safety and product integrity, such as food, pharmaceuticals and industrial goods, shrink film is a trusted packaging solution that supports compliance and customer confidence.

Does shrink wrap film help save storage and floor space?

Shrink wrap film helps optimize warehouse space by tightly conforming to palletized loads, reducing excess bulk and maximizing storage efficiency. This makes it especially valuable for facilities with limited floor space.

Because shrink film provides five-sided coverage, it eliminates the need for additional packaging materials while keeping loads neat and stackable. Pallets wrapped with shrink film can be stored closer together without risk of shifting or contamination, which is a major benefit in warehouses, distribution centers or outdoor storage yards. Millwood’s shrink film solutions not only protect goods but also help businesses manage storage costs more effectively by improving stacking and space utilization.

How does Millwood’s shrink film improve long-term cost savings?

Millwood’s shrink film provides cost savings through durability, space optimization and reduced product damage. While the upfront cost is higher than stretch film, it minimizes risks of loss, contamination and tampering over time.

Shrink wrap film’s ability to conform tightly to palletized goods ensures fewer damaged loads, less repackaging and improved product security during shipping and storage. By optimizing floor space and offering tamper-evident coverage, it also helps businesses cut indirect costs tied to warehouse inefficiency and product liability. Millwood’s industrial-grade shrink film solutions are designed for companies that prioritize long-term protection, stability and reliable performance across challenging storage and transport conditions.