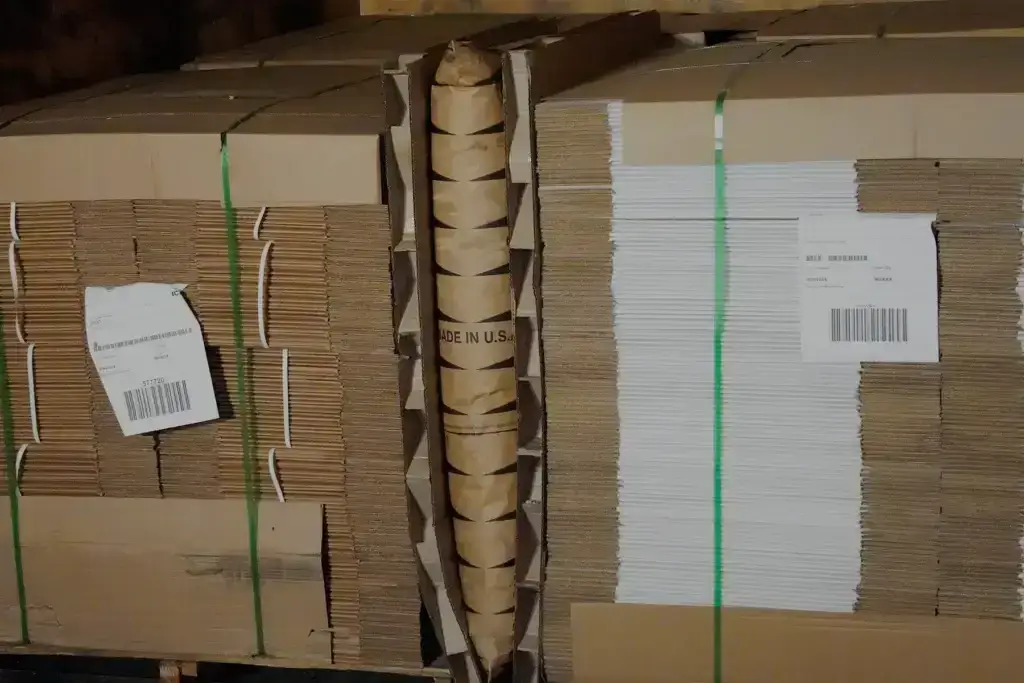

A-Frame Void Fill

Know What You're Looking For?

Need More Help With Your Load?

Recyclable Void Fill for Safer, More Sustainable Transport

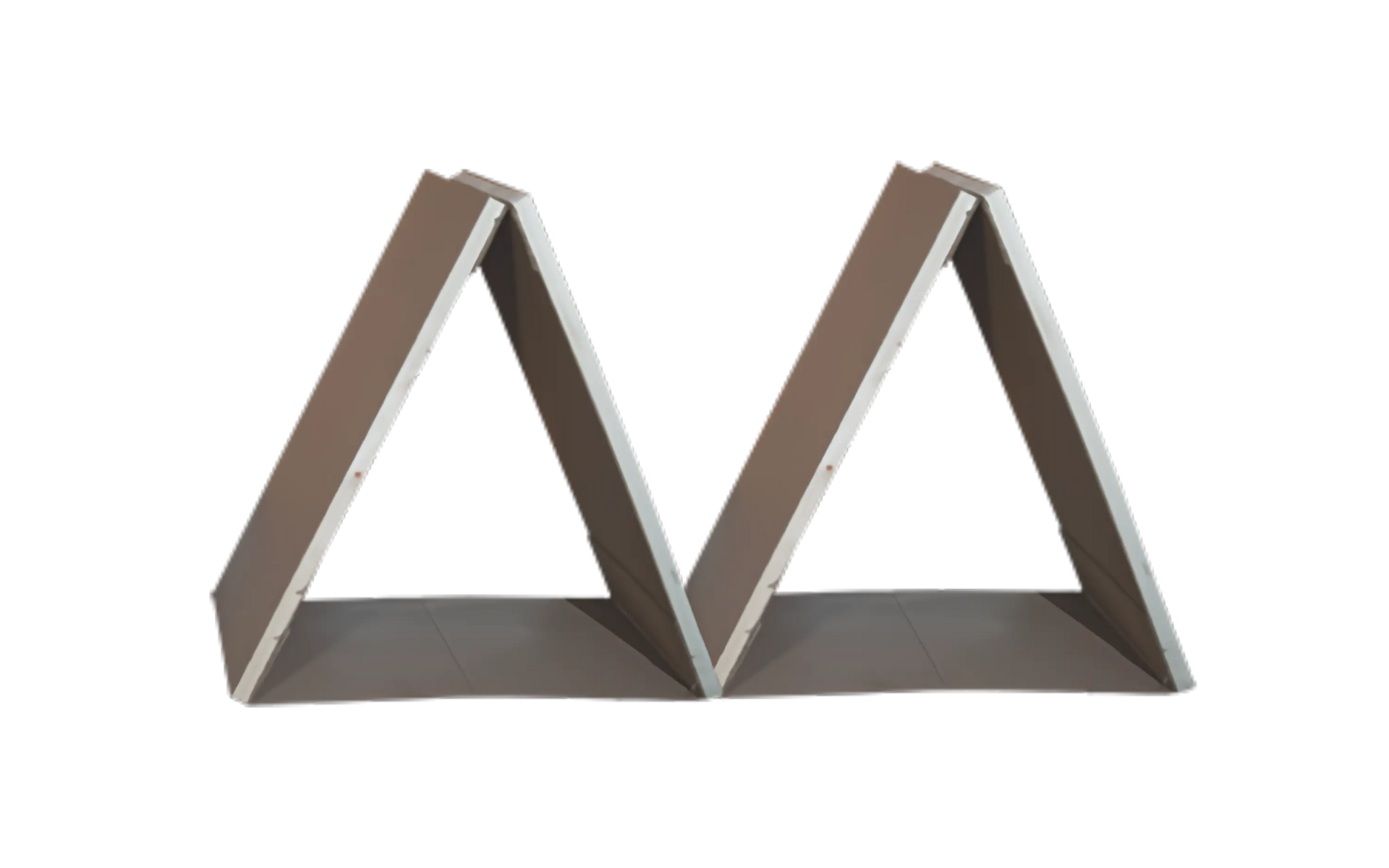

The A-Frame Void Filler is a recyclable void fill solution designed to stabilize cargo loads by filling the large nose space in over-the-road trailers. Built with a durable wooden frame, corrugated sheet overlay and reinforced crossbeam, it prevents freight from shifting forward while maintaining balanced weight distribution.

Strength and Stability in Every Shipment

This A-Frame Void Filler is engineered to stop cargo from moving lengthwise during transit. Instead of wasting pallets or scrap materials to fill gaps, this recyclable void fill option delivers a consistent, economical and eco-friendly alternative that supports safe delivery from start to finish.

Practical Applications Across Industries

Ideal for 53’ OTR trailers, the A-Frame Void Filler is custom-made to your specifications. It is widely used in food, beverage, paper and consumer goods shipping—anywhere stable, secure loads are critical. Fully recyclable and made in the USA, it reduces waste while keeping your freight protected.

Complex Packaging Needs? No Problem.

- Corner Defender – Reinforces 90° corners and prevents strapping abrasion.

- Edge Defender – Protects edges and strengthens unitization for better stability.

- Notch Defender – Provides durable corner and edge protection for heavy or high-impact loads.

Custom-made to order and 100% recyclable, the Defender Series delivers the protection, strength, and peace of mind your supply chain demands—because at Millwood, we’ve got every corner covered.

Why Choose Millwood As Your Single Source Provider?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our A-Frame Void Fill

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify, and optimize designs to reduce product damage, minimize waste, and improve supply chain efficiency.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your damage prevention needs.

Frequently Asked Questions

What is an A-Frame Void Filler and how does it work?

An A-Frame Void Filler is a recyclable dunnage system designed to fill trailer nose voids, preventing forward cargo shift and ensuring safe, stable shipments in over-the-road transport.

Built with a wooden frame, corrugated overlay and reinforced crossbeam, the A-Frame Void Filler locks cargo in place by stabilizing loads against forward movement. Unlike loose pallets or scrap materials, this engineered solution provides consistent strength and balanced weight distribution. Millwood custom-builds each void filler to fit 53’ OTR trailers, ensuring securement for food, beverage, paper and consumer goods. By preventing load collapse and reducing product damage, A-Frame Void Fillers deliver cost savings, efficiency and reliable freight protection across the supply chain.

Why choose a recyclable void fill instead of using pallets or scrap material?

Recyclable void fillers are safer, cleaner and more sustainable than using spare pallets or scrap materials to block cargo inside trailers.

Traditional blocking methods like pallets often waste space, add unnecessary weight or splinter during transport. A-Frame Void Fillers eliminate these risks by providing a purpose-built, lightweight and recyclable alternative. They reduce labor time, improve installation consistency and support corporate sustainability goals by cutting down on wood waste. Because they are custom-engineered, they offer predictable performance that scrap materials cannot match. Choosing recyclable void fillers helps companies improve load securement efficiency while reducing operational costs and environmental impact.

What trailers are A-Frame Void Fillers designed for?

A-Frame Void Fillers are engineered for 53’ over-the-road trailers, filling large nose gaps where freight would otherwise shift forward during transit.

The front void of a trailer is one of the most common weak points in freight stabilization. Without proper blocking, loads can slide forward during braking or uneven road conditions. Millwood’s A-Frame Void Filler is custom-sized to fit this space, stabilizing cargo ranging from beverages and food products to industrial and paper goods. By delivering strength and balance, these void fillers ensure safer transportation, protect cargo integrity and help shippers meet compliance standards across logistics operations.

Which industries benefit most from using A-Frame Void Fillers?

Industries that ship beverages, paper, food and consumer goods benefit most from A-Frame Void Fillers, as they require reliable load securement in 53’ trailers.

A-Frame Void Fillers are widely used in sectors where forward cargo shift is a frequent cause of product damage. Beverage distributors use them to stabilize bottled or canned products; paper mills use them to protect rolls during transit; and food or consumer goods companies rely on them to keep cartons intact. By ensuring freight remains secure in the trailer nose, A-Frame Void Fillers reduce damage claims, improve shipping safety and streamline logistics. Their recyclable design also supports sustainability initiatives in industries with high-volume shipping.

Are A-Frame Void Fillers cost-effective?

Yes—A-Frame Void Fillers reduce freight damage, minimize wasted materials and replace scrap pallets, making them a cost-effective load securement solution.

By preventing cargo shift and load collapse, companies save money on product claims, rework and transportation inefficiencies. Unlike disposable scrap or makeshift fillers, A-Frame Void Fillers are engineered for consistent performance and can be recycled after use, lowering both immediate and long-term costs. Their lightweight construction reduces trailer weight, contributing to fuel efficiency, while their easy installation lowers labor time. Millwood’s custom-engineered A-Frame Void Fillers provide a balanced solution that combines safety, sustainability and cost savings for shippers across industries.

Stronger Together

Millwood and Litco are affiliated companies, united in mission, purpose and culture. Together, we are strategically aligned to provide a more comprehensive range of pallets, load securement, packaging and supply chain solutions to a broader customer base, delivering greater value to our customers.