Cargo Separators

Know What You're Looking For?

Need More Help With Your Load?

Reliable Cargo Separator Solutions for Every Load

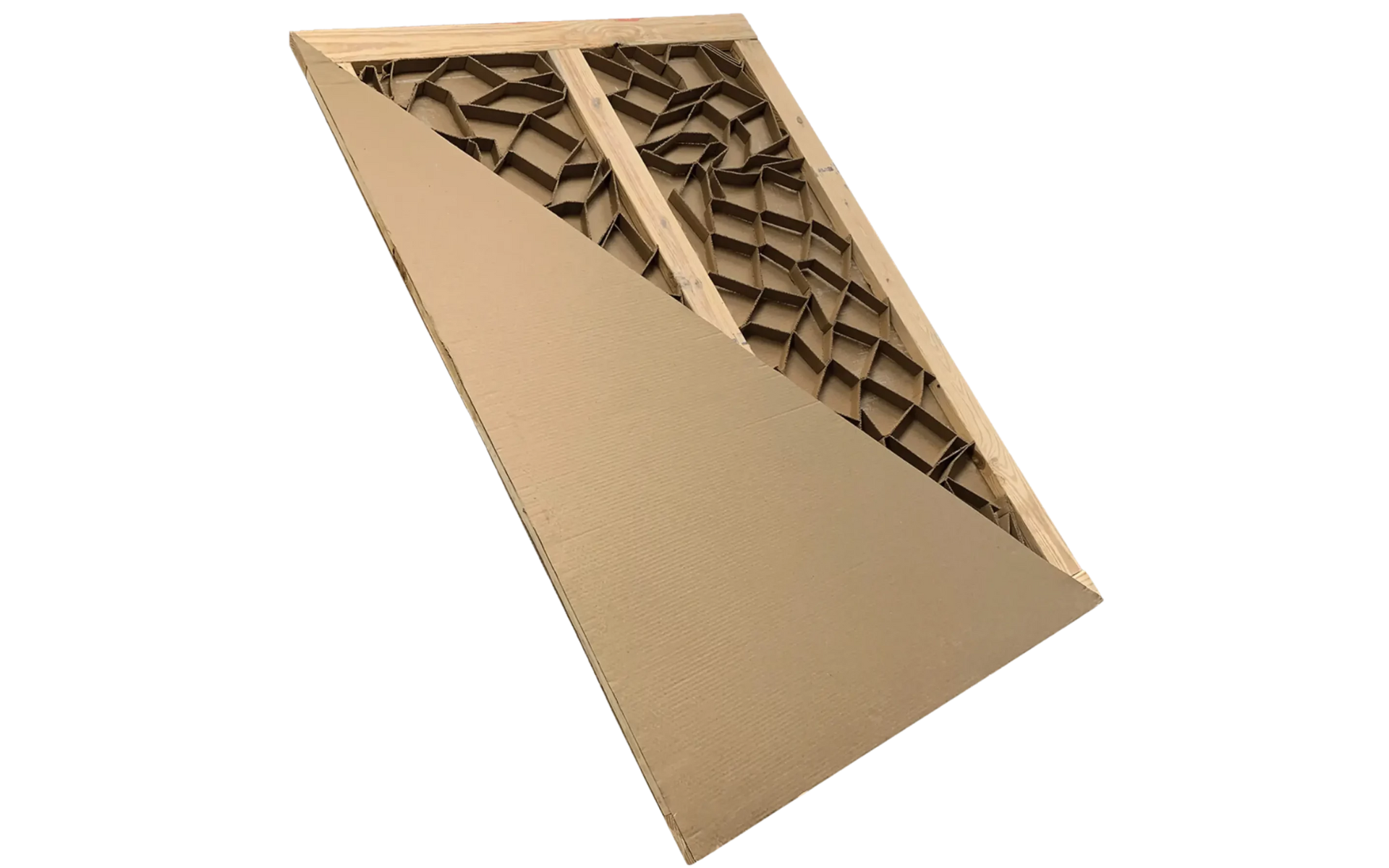

Cargo separators provide a safe, cost-effective way to stabilize shipments and prevent movement during transit. Whether used as cargo dividers, load separators or cargo separators, they ensure products stay secure in rail cars, trucks and shipping containers.

Protect Your Cargo in Transit

A cargo separator helps block forward, backward and side-to-side movement, reducing the risk of toppling and damage. From large industrial shipments to smaller packaged goods, load separators keep cargo organized and intact.

Maximize Storage and Stacking Efficiency

Cargo dividers are ideal for optimizing warehouse space. By keeping tall or heavy units separated from smaller loads, cargo separators allow for safe stacking, easier handling and improved operational efficiency.

Complex Packaging Needs? No Problem.

- Corner Defender – Reinforces 90° corners and prevents strapping abrasion.

- Edge Defender – Protects edges and strengthens unitization for better stability.

- Notch Defender – Provides durable corner and edge protection for heavy or high-impact loads.

Custom-made to order and 100% recyclable, the Defender Series delivers the protection, strength, and peace of mind your supply chain demands—because at Millwood, we’ve got every corner covered.

Why Choose Millwood As Your Single Source Provider?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Cargo Separators

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify, and optimize designs to reduce product damage, minimize waste, and improve supply chain efficiency.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your damage prevention needs.

Frequently Asked Questions

What is a cargo separator and why is it important?

A cargo separator is a lightweight divider used to stabilize freight, preventing side-to-side or forward movement during transit and protecting products from damage.

Cargo separators play a critical role in shipping by blocking palletized goods from shifting inside trailers, rail cars or containers. By keeping loads locked in place, they reduce the risk of tipping, breakage or product loss, helping businesses save money on damaged goods and claims. In warehouses, they improve safety by supporting double- or triple-stacking and preventing collapses. Millwood cargo separators are lightweight, splinter-free and easy to handle, making them a cost-effective alternative to heavy wood or OSB panels while still delivering dependable performance across supply chains.

How do cargo separators differ from plywood or OSB dividers?

Cargo separators are lighter, splinter-free, more consistent in performance and more economical than plywood or OSB dividers.

Unlike traditional dividers that can splinter, vary in quality or fluctuate in price, Millwood cargo separators are manufactured for durability and easy handling. They reduce the risk of injuries caused by rough edges, save on labor time due to their lighter weight and provide predictable protection for shipments. Additionally, they are often recyclable, making them a more sustainable choice for businesses with eco-focused supply chains. With customizable options to fit specific cargo types, separators outperform plywood in both safety and efficiency, making them a smarter long-term investment for freight operations.

What are the common use cases for cargo dividers and load separators?

Cargo dividers are used in truck trailers, rail cars and containers to block cargo movement and are also valuable in warehouses for stacking and load stability.

Shippers use cargo separators to stabilize pallets, drums, chemicals and packaged goods during transport. They reduce forward and backward shifting, especially during braking or sudden stops. In warehouses, separators allow for safe double- and triple-stacking of heavy or tall units without risking collapse. Industries such as retail, manufacturing and logistics rely on these load separators to maintain product integrity throughout the supply chain. Their versatility makes them an essential tool for companies aiming to cut shipping damage, improve safety and maximize space utilization.

Can cargo separators be customized for specific applications?

Yes—cargo separators can be designed with custom dimensions, reinforcement options and materials to match different shipping and storage needs.

Millwood works with customers to create separators that meet unique cargo requirements, whether that involves thicker cores for heavier loads, specific lengths for containerized shipping or reinforced panels for sensitive products. Customization ensures that separators balance strength, weight and efficiency while providing reliable protection. This tailored approach helps avoid under-engineering, which can lead to load failure and over-engineering, which adds unnecessary costs. By offering flexibility in design, Millwood ensures each cargo separator integrates seamlessly with customers’ logistics and warehouse systems.

Are cargo separators environmentally friendly?

Yes—cargo separators are made from recyclable materials and offer a more eco-friendly alternative to plywood or OSB dividers.

Millwood’s cargo separators support sustainability initiatives by reducing wood waste and enabling recyclability at the end of their lifecycle. Their lightweight construction also reduces fuel consumption in transport, lowering carbon footprint compared to heavier alternatives. Reusable and consistent in quality, separators help companies minimize waste, reduce environmental impact and meet corporate sustainability goals. By choosing eco-friendly load separators, businesses gain reliable freight protection while contributing to a greener supply chain, balancing product safety with responsible resource management.

Stronger Together

Millwood and Litco are affiliated companies, united in mission, purpose and culture. Together, we are strategically aligned to provide a more comprehensive range of pallets, load securement, packaging and supply chain solutions to a broader customer base, delivering greater value to our customers.