Hardwood

Back to Lumber and Panels

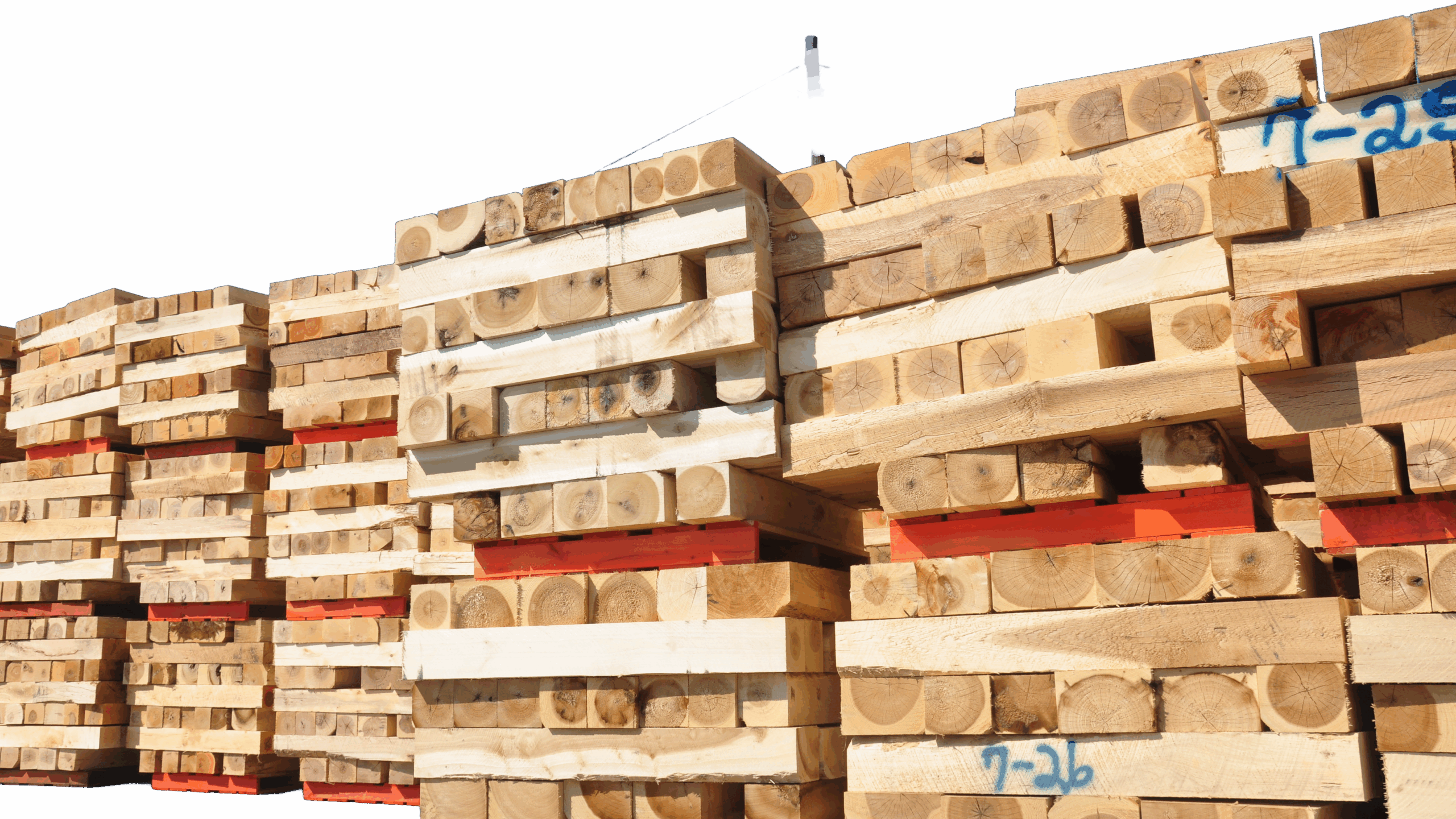

Hardwood Lumber Solutions for Industrial Applications

Our mixed hardwood lumber is manufactured and cut to size for specific customer applications, providing durable and reliable solutions for a wide range of industries. Whether you’re sourcing hardwood lumber online or working directly with us for bulk orders, we deliver consistency, performance and cost-efficiency.

Full and Mixed Truckload Delivery

We offer flexible delivery options to meet your needs, including both full and mixed truckloads. Customers can receive up to 7,800 board feet on an actual count or 10,500 on a nominal count before reaching maximum truckload weight.

Trusted Species and Quality Standards

Our most common industrial hardwoods include mixed density oaks and poplar, chosen for their strength and versatility. Each order of hardwood lumber is manufactured with precision to ensure dependable performance in tough environments.

Material Quality Concerns? No Problem.

- Material failures that weaken pallets, crates or unit loads

- Inconsistent quality that slows production or increases rework

Instead, we deliver a just-right material solution—balanced for durability, cost and steady supply—so your packaging performs the way it should from the first board to the final shipment.

Why Choose Millwood as Your Solution Provider?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your lumber needs.

Steel, polyester and polypropylene strapping engineered for load containment. Works with tensioners and sealers to secure heavy or high-value goods.

Certified blocking and bracing solutions that keep shipments secure during transport.

Certified pallet heat treatment that eliminates pests and ensures compliance with global ISPM-15 regulations. Export-ready, chemical-free and eco-friendly.

Frequently Asked Questions

Where can I buy hardwood lumber online in bulk quantities?

You can buy hardwood lumber online in bulk through companies like Millwood, Inc. which offers fast quotes, custom sizes and reliable delivery for industrial use. Ordering online streamlines procurement and standardizes specs across locations.

Buying hardwood lumber online through companies like Millwood helps centralize purchasing, reduce admin load and improve lead-time predictability. You can request quotes by species, grade, thickness and dimensions—then select cut-to-size or surfaced options to fit downstream needs. Whether you’re building pallets, crates, skids or heavy-duty packaging, online ordering supports consistent quality across facilities and simplifies reorders. With bulk programs, you’ll also gain volume-based pricing and consolidated freight, which lowers total landed cost. If your teams operate multiple plants, online workflows ensure the same lumber hardwood spec is delivered network-wide.

What hardwood lumber grades and species are typically available?

Most suppliers offer common industrial hardwood species—such as oak, maple, poplar and ash—across utility to higher grades for packaging and production.

For packaging and industrial applications, hardwood lumber selection often centers on strength, availability and cost efficiency. Oak provides high load-bearing capacity for heavy pallets and skids. Maple offers consistent density and durability for precision components. Poplar balances strength and weight, making it a popular option for crates and protective dunnage. Ash provides shock resistance for demanding transport. Grades range from industrial/commons to higher appearance grades, depending on your needs. When you buy hardwood lumber online, you can specify species, grade, thickness, surfacing (S2S/S4S) and tolerances to match your process and performance targets.

How is hardwood lumber priced for industrial buyers?

Pricing depends on species, grade, thickness, surfacing and volume. Bulk purchases typically earn better per-unit costs and more efficient shipping.

Hardwood lumber is commonly priced by board foot, with cost drivers including species scarcity, grade quality, moisture content and machining requirements (e.g., planing, ripping, cut-to-length). Buyers seeking pallet- and crate-grade materials can optimize budget by standardizing specs and consolidating orders across facilities. When you purchase hardwood lumber online, you can compare options quickly and secure quotes that reflect volume tiers and recurring orders. Aligning forecasting with suppliers improves availability and locks in consistent pricing over time. Ask about minimums, mixed-unit shipments, and bundled freight to lower your total landed cost.

What sizes and machining options are available for hardwood lumber?

Expect common thicknesses (e.g., 4/4–12/4), custom widths and lengths and machining such as S2S/S4S, ripping and cut-to-size for production-ready use.

Industrial users value hardwood lumber that arrives close to ready for assembly—especially for pallets, skids, crates and protective packaging. Standard thicknesses cover most applications, while custom widths and lengths reduce shop time and waste. Surfacing and ripping services tighten tolerances and improve throughput on production lines. When you order hardwood lumber online, specify your preferred moisture content, surfacing level and exact dimensions. The more you standardize across plants, the easier it becomes to control quality, increase yield and streamline inventory management for lumber hardwood programs.

Which industries benefit most from hardwood lumber?

Industries that rely on blocking and dunnage, pipeline skids, pallet components, crane mats, tunnel lagging and shoring depend heavily on hardwood lumber for strength, stability and durability. These applications require dense, load-bearing wood that can withstand stress.

Hardwood lumber is widely used across industries that need rugged, reliable materials for high-stakes operations. In manufacturing and logistics, hardwood is cut into blocking and dunnage to secure loads in transit. The energy and utilities sector relies on pipeline skids to stabilize heavy pipelines during installation and maintenance. Packaging companies use hardwood for pallet components to ensure consistent load performance. Construction firms depend on crane mats for equipment stability on challenging terrain, while tunneling projects use lagging and shoring for underground reinforcement. Hardwood also serves as blocks and wedges in industrial applications requiring precision and strength. When sourced strategically, lumber hardwood delivers durability and consistency across all of these industries.