Packaging Lumber

Back to Lumber and Panels

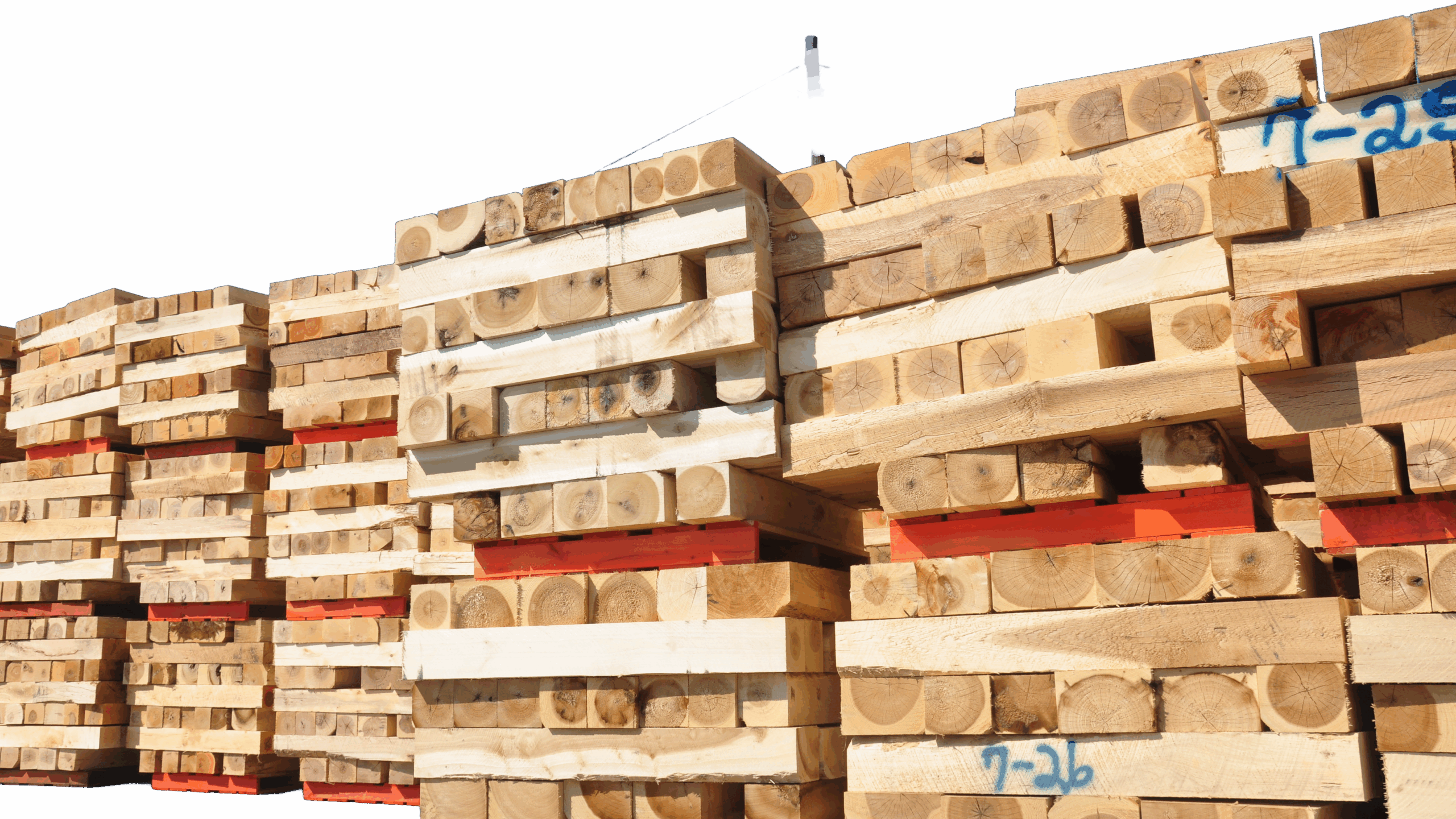

Packaging Lumber for Industrial & Shipping Applications

When shipping or storing valuable products, the right packaging lumber makes all the difference. Businesses across industries rely on durable, custom-cut lumber to protect goods, stabilize shipments and ensure supply chain efficiency. Whether you need blocking, bracing or crating, packaging lumber provides strength, reliability and peace of mind.

Why Choose Packaging Lumber for Shipping and Industrial Use?

Packaging lumber is designed to withstand the heavy demands of industrial use and global supply chains. Unlike general-purpose wood, it is cut and processed to handle stress, minimize product damage and support a wide range of shipping applications. By choosing custom packaging lumber, you reduce waste, save costs and improve protection for every load.

Common Applications of Packaging Lumber

Packaging lumber is versatile, serving as the backbone for crating, dunnage, blocking and bracing. It stabilizes cargo during transportation, supports pallets and strengthens shipping containers. Industries from logistics to construction depend on it for reliable protection. Packaging lumber also plays an important role in heavy equipment shipping, ensuring even the most fragile or oversized items reach their destination safely.

Material Quality Concerns? No Problem.

- Material failures that weaken pallets, crates or unit loads

- Inconsistent quality that slows production or increases rework

Instead, we deliver a just-right material solution—balanced for durability, cost and steady supply—so your packaging performs the way it should from the first board to the final shipment.

Why Choose Millwood as Your Solution Provider?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your lumber needs.

Steel, polyester and polypropylene strapping engineered for load containment. Works with tensioners and sealers to secure heavy or high-value goods.

Certified blocking and bracing solutions that keep shipments secure during transport.

Certified pallet heat treatment that eliminates pests and ensures compliance with global ISPM-15 regulations. Export-ready, chemical-free and eco-friendly.

Frequently Asked Questions

What is packaging lumber used for?

Packaging lumber is used to protect, block and secure goods during shipping and storage.

Packaging lumber provides structural strength and durability for transporting heavy or fragile items. It is commonly used in crating, blocking and bracing to stabilize shipments, protect sensitive equipment and ensure products arrive safely. Industries like manufacturing, construction and logistics rely on packaging lumber to keep supply chains efficient and prevent costly damages. By using packaging lumber, businesses minimize the risk of shifting loads, broken items and safety hazards, while maintaining compliance with shipping standards.

How does custom packaging lumber benefit supply chains?

Custom packaging lumber improves efficiency, reduces waste and optimizes product protection in transit.

Instead of relying on generic sizes, custom packaging lumber is cut to fit the exact requirements of each application. This ensures a stronger fit for crates, pallets and shipping containers while eliminating unnecessary material use. For businesses, that translates into cost savings, fewer damaged shipments and streamlined packaging processes. Custom packaging lumber also supports sustainability goals by reducing excess waste and maximizing the use of raw materials. With tailored solutions like this, companies enjoy greater consistency across their supply chains and increased customer satisfaction.

Which industries rely on packaging lumber?

Industries that rely on packaging lumber include manufacturing, logistics, energy and defense.

Packaging lumber plays an essential role in many sectors. Manufacturers use it for crating and protecting equipment, logistics companies depend on it for blocking and bracing cargo, and energy companies rely on it for pipeline skids and heavy machinery transport. Defense contractors also use packaging lumber for securing large and sensitive equipment in transit. From aerospace to construction, industries that need reliable, durable and cost-effective packaging solutions choose packaging lumber to safeguard their products across complex supply chains.

Can packaging lumber be customized for specific shipping needs?

Yes, our packaging lumber can be custom cut and designed to match specific shipping requirements for your products.

Every shipment has unique demands, whether you’re sending heavy machinery, fragile goods or bulk products. Our custom packaging lumber solutions allow you to optimize load protection, minimize damage and enhance shipping efficiency. This includes tailoring sizes, thicknesses and designs to provide secure bracing, blocking or pallet bases. For industries requiring specialized applications, our packaging lumber can also be integrated with dunnage, skids or crating systems designed for particular weights and dimensions. By aligning with your supply chain needs, custom lumber reduces waste, lowers costs and ensures goods arrive in top condition. This flexibility makes it an essential part of strategic shipping and logistics planning.

Do packaging wood materials meet international shipping requirements?

Yes, packaging wood materials can meet international shipping requirements when they are heat-treated and carry the ISPM 15 stamp.

International shipping requires compliance with phytosanitary regulations to prevent pests and diseases from spreading across borders. The most widely recognized standard is ISPM 15, which requires wood packaging such as pallets, crates and dunnage to be heat-treated or fumigated. Compliant products carry the ISPM 15 stamp, a mark recognized worldwide that ensures your shipments meet customs standards and avoid costly delays or rejections. Packaging lumber that is ISPM 15 certified gives peace of mind, particularly for exporters shipping to markets in Europe, Asia and beyond. By choosing certified packaging wood, companies protect both their goods and their international trade relationships.