Specialty & Pre-Cut Products

Back to Lumber and Panels

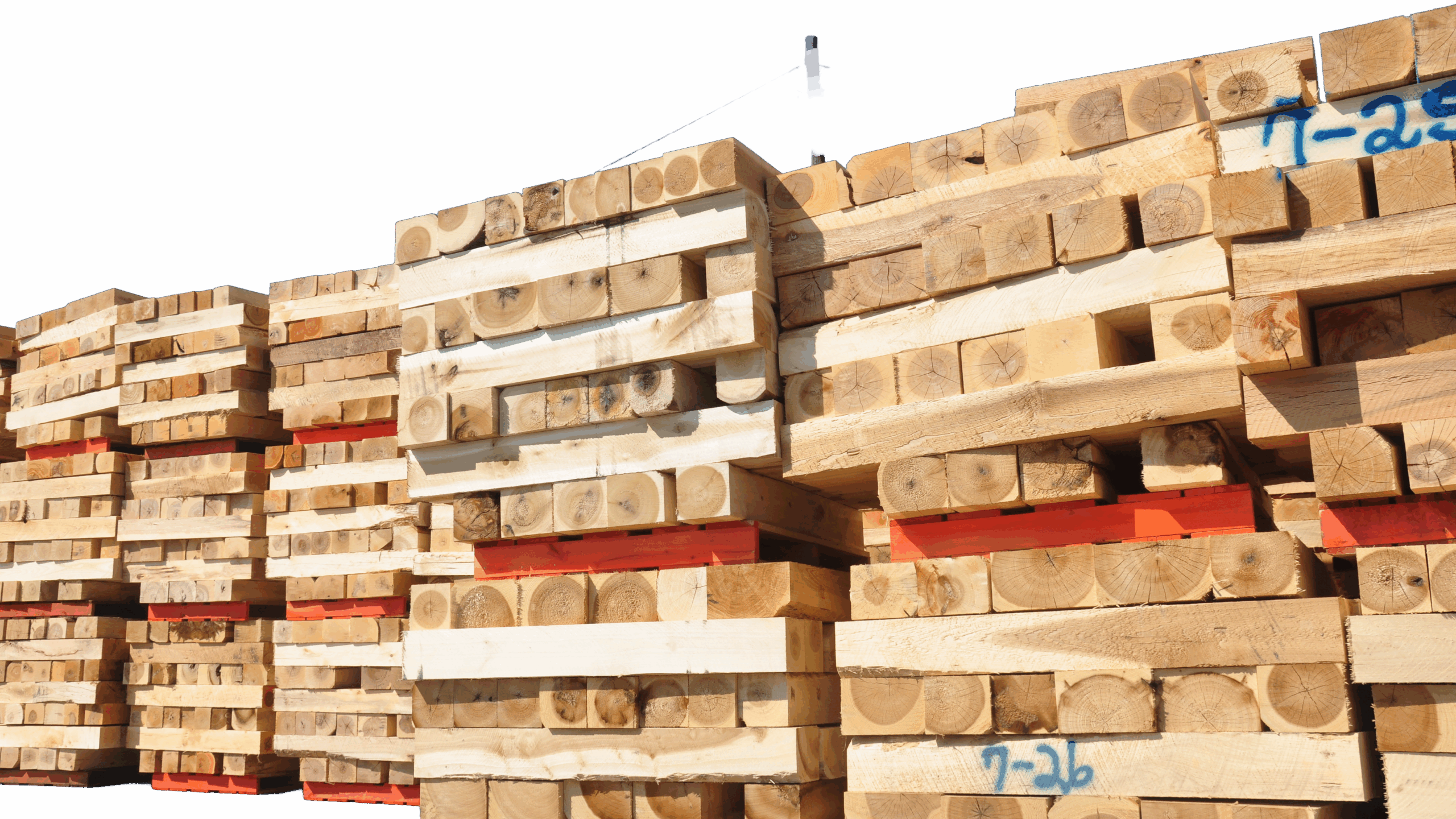

Specialty Wood Products & Pre-Cut Lumber Solutions

Millwood provides high-quality specialty wood products and precisely milled custom cut lumber designed to save time, reduce waste and deliver unique value for builders, manufacturers and craftsmen. From exotic hardwoods and reclaimed slabs to pre-cut framing studs and S4S boards, our specialty lumber products are built to meet both aesthetic and performance needs.

What Makes Specialty Lumber Different?

Specialty lumber is defined by its exceptional qualities—rare species, clear domestic hardwoods, reclaimed wood or unique cuts like quarter-sawn boards. These materials are sought after for cabinetry, furniture and architectural features where strength and beauty are equally important.

The Advantages of Pre-Cut Pieces

Pre-cut lumber saves time and increases efficiency by arriving ready to use. From construction studs milled to precise wall heights to plywood panels, craft woods or full component kits, pre-cut pieces reduce job-site labor and material waste.

Material Quality Concerns? No Problem.

- Material failures that weaken pallets, crates or unit loads

- Inconsistent quality that slows production or increases rework

Instead, we deliver a just-right material solution—balanced for durability, cost and steady supply—so your packaging performs the way it should from the first board to the final shipment.

Why Choose Millwood as Your Solution Provider?

-

Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

-

Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

-

Sustainability Commitment: We are committed to efficiency without compromising our environment.

PROVIDING SUPPLY CHAIN SOLUTIONS

We’ve hand-picked these products to create a comprehensive solution that complements your lumber needs.

Steel, polyester and polypropylene strapping engineered for load containment. Works with tensioners and sealers to secure heavy or high-value goods.

Certified blocking and bracing solutions that keep shipments secure during transport.

Certified pallet heat treatment that eliminates pests and ensures compliance with global ISPM-15 regulations. Export-ready, chemical-free and eco-friendly.

Frequently Asked Questions

What are specialty wood products and how are they used?

Specialty wood products are precision-cut wood materials designed for specific industrial uses, offering efficiency, safety and consistency.

Specialty wood products provide tailored solutions for companies which need wood components to meet exact specifications. Unlike rough lumber, specialty products are carefully cut and processed to ensure uniformity, reduce waste and improve handling safety. These products are essential in manufacturing, construction, packaging and logistics where precision and durability are non-negotiable. Whether for pallets, crates, blocking, or dunnage specialty wood products provide the right fit for demanding supply chains. By investing in specialty wood products, businesses gain cost savings, improved workflow and reliable performance across all locations.

How do specialty lumber products differ from standard construction lumber?

Specialty lumber products are cut, graded and processed for unique applications, while standard construction lumber serves general building needs.

The main difference between specialty lumber and standard construction lumber lies in precision and purpose. Standard construction lumber is mass-produced for framing, flooring, or structural work, with uniform dimensions and grading focused on general building requirements. Specialty wood products, by contrast, are tailored for specific applications such as pallet components, dunnage, tunnel lagging or crane mats. This often involves custom cutting, unique dimensions or higher-grade specifications that standard construction lumber cannot meet. Specialty lumber also supports industries like logistics, heavy construction and energy by addressing safety, load-bearing and durability concerns where precision and reliability are non-negotiable.

What are the advantages of custom cut lumber?

Custom cut lumber reduces waste, saves time and ensures every piece fits perfectly in its application.

Custom cut lumber eliminates the inefficiencies of cutting wood in-house. By ordering lumber pre-cut to your specifications, you save time on labor, reduce on-site errors and achieve better consistency across production runs. This process minimizes scrap wood, improves safety by reducing handling and ensures your wood components meet performance expectations every time. Industries that depend on strict specifications, such as packaging, shipping and heavy manufacturing, benefit the most from custom cut lumber. Tailored sizes mean faster assembly, stronger end products and streamlined supply chain operations.

Which industries benefit most from specialty wood products?

Industries that need durable, consistent wood materials — like manufacturing, logistics and energy — benefit most.

Specialty wood products play an essential role in industries where performance and precision matter. Packaging companies rely on specialty lumber for pallets and crates that meet exact load requirements. Logistics and transportation benefit from dunnage that keeps shipments stable during transit. Heavy industries such as construction and energy use custom cut lumber for blocking, skids and other structural supports. Even aerospace and defense industries depend on specialty wood products for safe, consistent handling of sensitive equipment. Wherever consistency, strength and custom sizes are required, specialty wood products provide the right solution.

How do specialty wood products support sustainability goals?

Specialty wood products reduce waste by providing precisely cut materials that maximize efficiency and resource use.

Sustainability is a growing priority in every industry and specialty wood products can play an important role. By ordering custom cut lumber that meets exact specifications, businesses reduce off-cuts, scrap, and inefficient use of raw materials. This lowers waste sent to landfills and optimizes the lifecycle of harvested wood. Suppliers like Millwood also source responsibly, ensuring lumber aligns with industry sustainability standards. Choosing specialty lumber means less need for excess inventory, reduced transport inefficiencies and a measurable improvement in your company’s environmental footprint. It’s a practical way for companies to meet both operational and ESG goals while saving money.