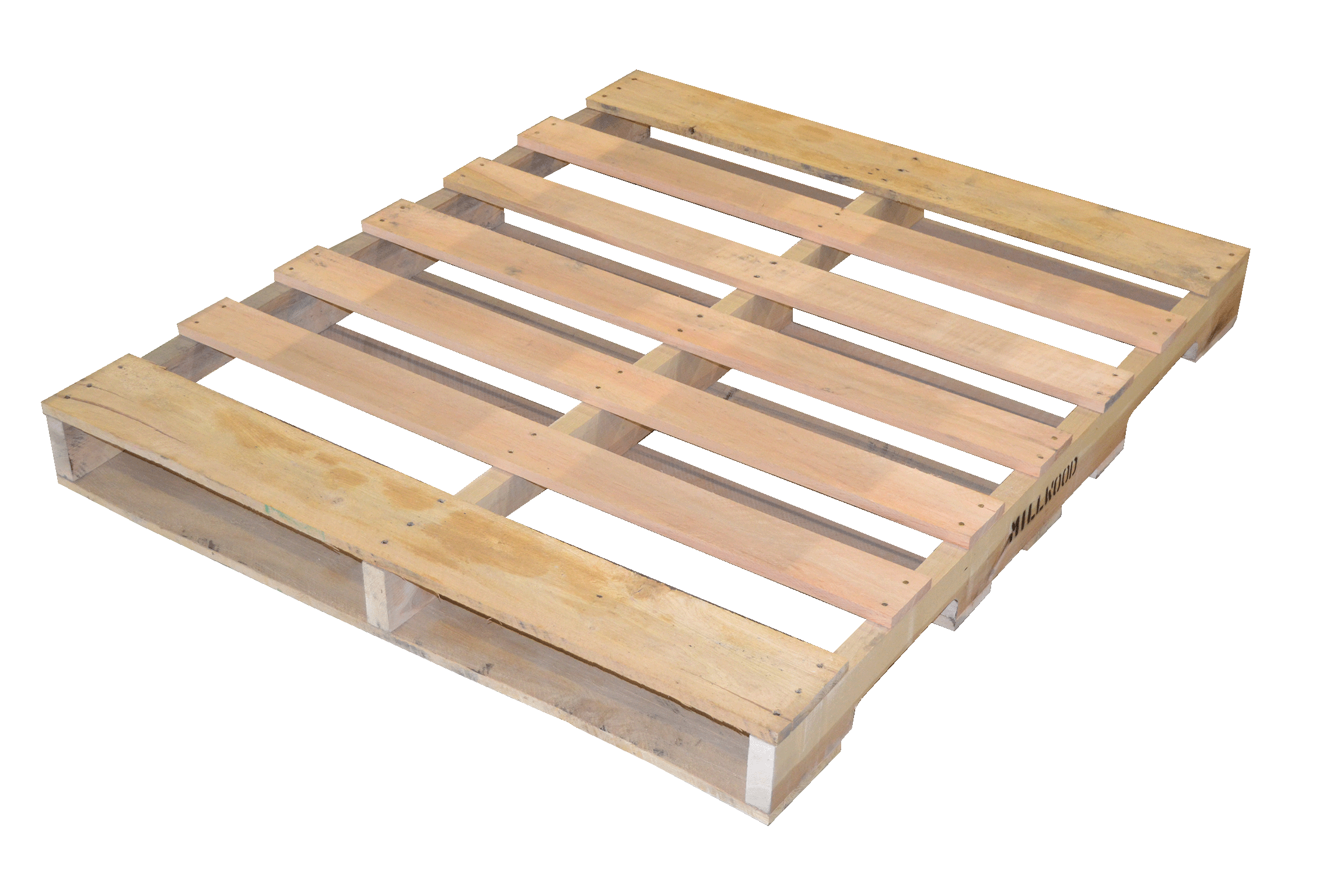

Combo Pallets

Know What You're Looking For?

Need Help With Your Pallet?

Combo Pallets | Cost-Effective Remanufactured Pallet Solutions

Millwood offers reliable combo pallets—remanufactured using a blend of recycled and new materials—to provide a cost effective, sustainable alternative to new pallets. Each combo pallet is carefully inspected, repaired and rebuilt to meet your specific load, handling and shipping requirements.

Balanced Performance and Savings

Combo pallets are engineered to deliver consistent strength at a lower price point than new builds. By combining recycled components with new lumber, Millwood can create pallets that reduce costs, extend product life cycles and support corporate sustainability goals.

Built to Your Application

Our team uses the Pallet Design System (PDS) and our ISTA-certified Packaging Lab to evaluate and engineer combo pallet designs that match your exact requirements. Whether you need a GMA 48×40 or custom size, Millwood ensures compliance, durability and safety.

Stringer pallets are the most widely used pallet design in North America, offering dependable strength and versatility. They can be built as two way or partial four way entry, making them a cost effective choice for many industries.

-

Standard sizes including 48x40 GMA

-

Cost effective and widely available

-

Reliable for most warehouse and shipping needs

-

Options for recycled, combo or new builds

Wood block pallets are a durable, high performance load unitization solution designed for today’s supply chains. Built with nine solid wood blocks, they provide a true four way entry, allowing forklifts and pallet jacks to access from any side.

-

Four-way entry for easier handling

-

Strong and durable construction

-

Ideal for automation and export programs

Custom pallets are designed to meet your unique load, size and handling requirements. Whether block or stringer style, Millwood engineers pallets that deliver protection, efficiency and value for specialized applications.

-

Tailored to exact product specs

-

Ideal for automation and export programs

-

Engineered with Millwood’s Packaging Science Lab support

-

Options for heavy duty or specialty applications

We want our customers to find the best product solutions for your process. Listed below are the common sizes for pallets. If you don’t see a size that would work for you, we would love to help you figure out a custom pallet, custom designed for you.

48×40 | 48×42 | 48×44 |

|---|---|---|

48×45 | 48×48 | 42×48 |

36×36 | 32×30 | 30×30 |

Custom Requirements? No Problem.

- Under-engineering that can result in pallet failure and product damage

- Over-engineering that drives up unnecessary costs and excess freight weight

- Instead, we deliver a just-right solution—balanced for strength, cost, and performance

Why Choose Millwood as Your Pallet Supplier?

- Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

- Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and design services enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

- Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Stringer Pallets

We will work to understand the problems you are having and as a team to provide solutions.

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify, and optimize designs to reduce product damage, minimize waste, and improve supply chain efficiency.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover, and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

More than just a pallet supplier

We’ve hand-picked these products to create a comprehensive solution that complements your pallet needs.

Frequently Asked Questions

What is a combo pallet?

A combo pallet is a remanufactured pallet built from both recycled and new lumber components. This design balances cost savings with reliable performance.

Combo pallets are ideal when operations require the durability of new pallets but want to reduce costs and environmental impact. Millwood inspects and rebuilds each pallet, replacing compromised deck boards or stringers with new lumber. This hybrid approach ensures structural integrity and consistency for handling, shipping and storage, making combo pallets a trusted option for companies prioritizing sustainability and budget efficiency.

How do combo pallets compare to used pallets?

Combo pallets differ from standard used pallets by including new lumber in their build, which improves consistency and strength.

While used pallets are repaired and recirculated, combo pallets undergo a deeper rebuild process. Weak or missing components are replaced with new wood, extending performance life. This makes them more uniform and reliable than general recycled pallets. Combo pallets are especially valuable for businesses needing a sustainable yet stronger solution without paying full new pallet pricing, striking a balance between quality and affordability.

Are combo pallets suitable for export?

Yes, combo pallets can be heat treated for ISPM-15 compliance, making them suitable for international shipping.

Millwood provides heat treatment services to ensure your combo pallets meet global phytosanitary regulations. Our vertically integrated operations allow us to control lumber sourcing, drying and treatment, ensuring that combo pallets maintain both regulatory compliance and structural durability. This makes them a practical option for businesses seeking cost savings while maintaining safe and compliant export practices across multiple shipping lanes.

What industries benefit most from combo pallets?

Combo pallets are widely used in industries balancing cost control with performance needs, such as manufacturing, distribution, building materials and consumer goods.

Companies with high pallet turnover appreciate the savings of remanufactured designs while retaining dependable strength. From warehouses to retail supply chains, combo pallets help reduce waste and extend usable pallet life. Millwood’s ability to engineer pallets for specific loads and applications ensures each industry—from automotive to food and beverage—receives a safe, sustainable and cost efficient solution tailored to operational demands.

Why choose Millwood for combo pallets?

Millwood combines decades of pallet expertise with service across North America, ensuring quality, compliance and supply chain reliability.

Our team goes beyond simple repair by leveraging the Pallet Design System (PDS) and ISTA-certified lab to optimize performance. Millwood’s recycling and remanufacturing programs reduce landfill impact, align with corporate sustainability initiatives and deliver consistent, just right pallet solutions. With vertically integrated operations and extensive distribution, we are equipped to supply combo pallets at scale—backed by the service and stewardship that set Millwood apart.