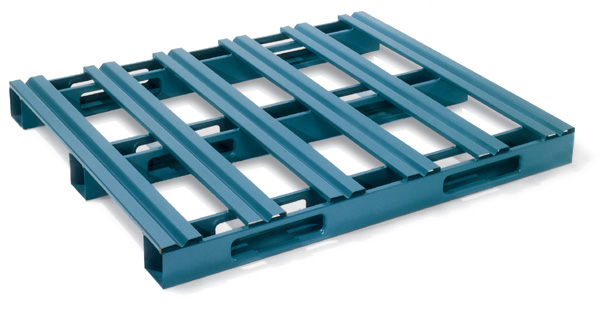

Metal Pallets

Know What You're Looking For?

Need More Help With Your Pallet?

Metal Pallets Engineered for Strength, Safety and Longevity

Metal pallets are among the most durable pallet alternatives available, designed to perform under the heaviest industrial demands. Whether you need a steel pallet for tool and die equipment that moves only a few times a year, or a returnable pallet solution for high-volume manufacturing, Millwood builds reliable, long-lasting designs that deliver strength, safety, and value across your supply chain.

Why Choose Metal Pallets Over Wood?

Traditional wood pallets can struggle with insects, fire risk, and shorter service life. A metal design eliminates those issues, offering consistent performance in harsh environments.

Steel pallets can support up to twenty times the weight of wood and last 10–15 years or longer — reducing replacement costs and supporting sustainability goals.

Use Cases for Steel and Aluminum Pallets

These durable pallet solutions excel in heavy manufacturing and closed-loop systems where reliability is critical.

Automotive suppliers use steel pallets and racks for glass and components, while manufacturers depend on aluminum designs for lighter, corrosion-resistant transport. Each material option offers long-term performance that supports high-value, high-demand operations.

Key Advantages:

Custom-Engineered for Every Requirement

No two operations are the same. That’s why our design engineers use data-driven modeling at the ISTA-certified Millwood Lab to tailor each pallet to your specific load and handling requirements.

Our approach ensures the right balance of performance and cost:

-

Avoiding under-engineering that can lead to pallet failure

-

Preventing over-engineering that adds unnecessary expense and freight weight

-

Delivering a just-right solution optimized for your product and process

Why Choose Millwood as Your Pallet Supplier?

- Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

- Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions

. - Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

- Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Stringer Pallets

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify and optimize designs to reduce product damage, minimize waste and improve supply chain efficiency.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

More than just a pallet supplier

We’ve hand-picked these products to create a comprehensive solution that complements your pallet needs.

Produced in our state of the art facility on Lordstown, Ohio our corner protectors are designed to protect your load from strapping abrasion and other damage.

Hand and machine stretch wrap options that contain loads, prevent shifting and protect against dust and moisture with cost-efficient application.

Turntable, overhead and robotic stretch wrapping machines engineered to reduce film use and provide consistent, reliable load stability.

Frequently Asked Questions

What are metal pallets and why are they better than wood pallets?

Metal pallets, including steel pallets and aluminum pallets, are built for extreme durability and long-term use, making them a stronger and more sustainable alternative to wood pallets.

Traditional wood pallets often face issues with pests, fire hazards and limited lifespans. A metal pallet solves these problems by resisting insects, moisture and flames while maintaining structural integrity under heavy loads. Steel pallets can hold up to twenty times the weight of a typical wood pallet and last 10–15 years, compared to wood’s 1–2 uses in some applications. Aluminum pallets are lighter, corrosion-resistant and ideal for industries with strict hygiene requirements like food, beverage and pharmaceuticals. For companies managing high-value products or closed-loop supply chains, metal pallets reduce long-term costs, improve safety and support sustainability initiatives.

How much weight can a steel pallet hold?

A steel pallet can hold loads up to twenty times heavier than a standard wood pallet, making it the preferred choice for industries handling oversized or high-value materials.

In manufacturing and industrial applications, steel pallets are engineered to move tool and die components, heavy equipment, automotive glass and other materials that cannot be safely carried on wood. Because of their design, steel pallets withstand repeated use in closed-loop systems where durability is essential. Unlike wood pallets, which can fail under extreme weight, a steel pallet protects both the product and workers handling it. This strength makes steel pallets a long-term investment for businesses seeking to minimize damage, streamline handling and extend pallet lifespans well beyond wood alternatives.

What industries use aluminum and steel pallets?

Metal pallets are widely used in industries that demand strength, hygiene and long-term reliability, including automotive, aerospace, food & beverage, pharmaceutical and military supply chains.

Aluminum pallets are ideal for hygienic or export applications because they are lightweight, non-porous and resistant to corrosion. This makes them a strong choice for pharmaceuticals, clean-room environments and international shipping where compliance matters. Steel pallets, on the other hand, are heavier and designed for industries such as automotive, aerospace, heavy equipment and tool & die manufacturing. These sectors often rely on closed-loop or returnable systems where steel pallets can be reused for years without failure. By tailoring the choice of aluminum or steel pallets to the application, businesses achieve a balance of safety, compliance and ROI.

How long do aluminum and steel pallets last?

Metal pallets typically last 10–15 years or more, compared to the short lifespan of wood pallets, which may need replacing after just a few uses.

The lifespan of a metal pallet depends on material, design and environment. Steel pallets are extremely rugged and often described as “outliving their users” in manufacturing environments. They can be used for decades in closed-loop or facility-only systems where durability is paramount. Aluminum pallets, while lighter, are also long-lasting and resistant to corrosion, making them a reliable solution for hygienic or export needs. Because they can be reused hundreds or even thousands of times, both aluminum and steel pallets deliver significant long-term cost savings and sustainability benefits by reducing waste and replacement frequency.

Are metal pallets cost-effective for my business?

Yes. While metal pallets have a higher upfront cost than wood, their durability and lifespan generate strong ROI through reduced replacements and supply chain efficiency.

A steel or aluminum pallet may cost several times more than wood at purchase, but it can last 10–15 years and handle loads wood cannot. This eliminates frequent replacement cycles and minimizes the risk of product damage or safety issues. For closed-loop systems, where pallets circulate repeatedly between facilities, the savings compound over time. In addition, using metal pallets supports sustainability initiatives by reducing waste and meeting compliance standards for industries with strict hygiene or safety requirements. Many businesses recover their initial investment within the first year of use, making metal pallets a cost-effective long-term solution.

Where can I buy custom metal pallets?

Millwood designs and supplies custom metal pallets, including steel and aluminum solutions, built to your exact specifications.

Our team works with customers across industries to engineer pallets that fit unique dimensions, load requirements, and handling environments. From automotive racks to returnable systems and export-ready aluminum pallets, Millwood has the expertise to deliver solutions tailored to your supply chain. With decades of experience in pallets, crating and packaging systems, we help customers improve efficiency, reduce costs and streamline their logistics. Whether you need a standard heavy-duty steel pallet or a lightweight aluminum pallet for clean-room use, Millwood can design a custom solution. [Request a Quote ➝]