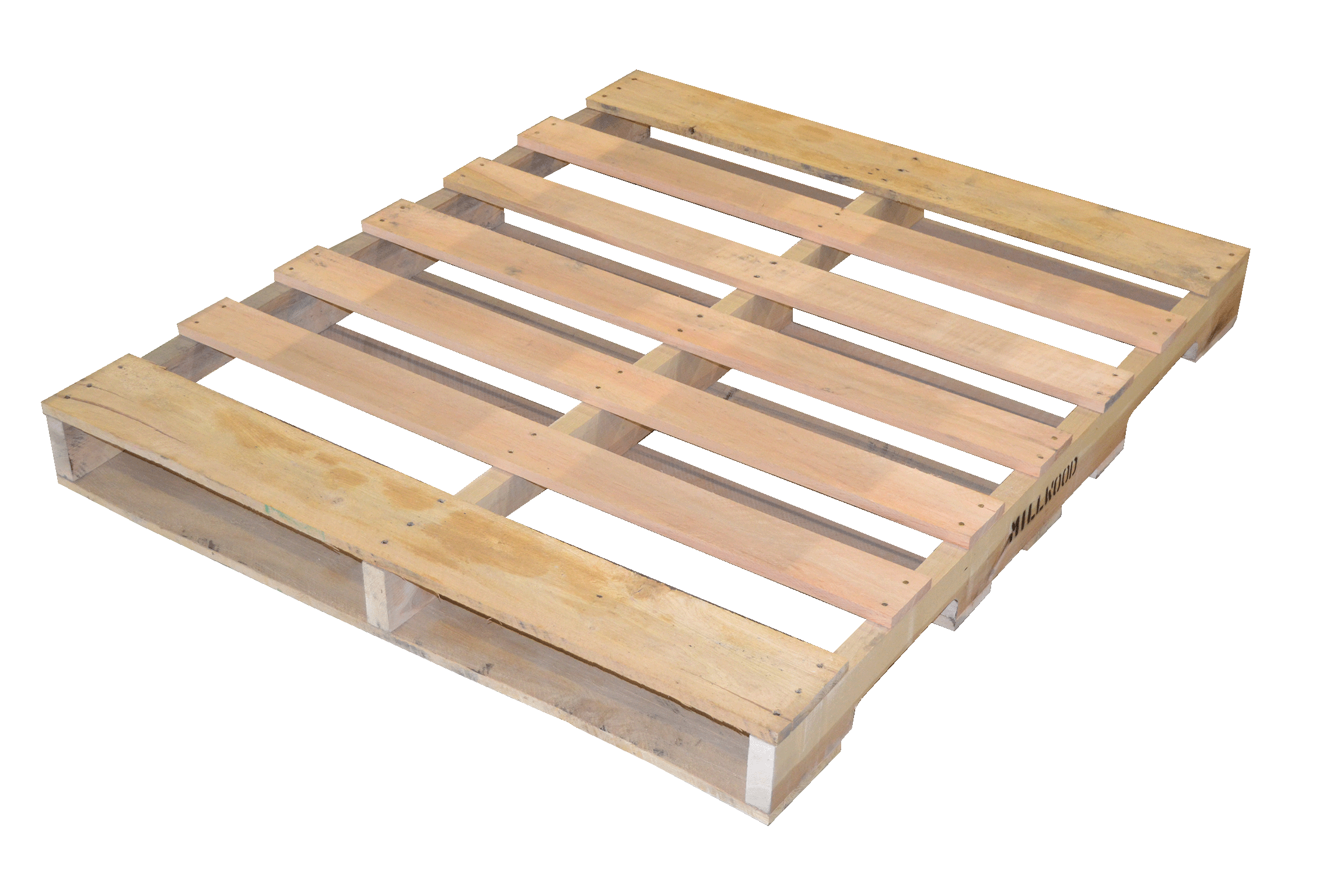

Stringer Pallets

Know What You're Looking For?

Need Help With Your Pallet?

Stringer Pallets for Shipping & Warehouse Storage

More than 80% of pallets used in the U.S. are stringer pallets—a trusted, cost-effective choice for a wide range of industries. Built with top and bottom deck boards supported by stringers (or runners), these wood stringer pallets offer reliable strength and proven performance for everyday shipping and warehouse needs.

Versatile Entry Options & Sizes

Available in both two-way entry and four-way entry styles, our 48×40 stringer pallets are the standard for most industries. With forklift access on all four sides and pallet jack access on two, these pallets deliver the handling flexibility your operation requires.

Built for Your Exact Application

Whether you need new, recycled or remanufactured stringer pallets, we will design and build the right stringer pallet for you and your application while delivering the cost efficiencies and performance that you are looking for. Read a Case Study —>

Millwood’s new stringer pallets are custom-built to your exact specifications and engineered for dependable performance. Whether hand-crafted or produced with automated machinery, they deliver durability and precision. Designed for multiple trips, they can later be repaired and reintroduced as recycled pallets to extend their value.

-

Long Service Life

-

Precision & Consistency

-

Custom Sizes Available

-

Lifecycle Value

Used stringer pallets are a cost-effective and sustainable choice. Each pallet is inspected, graded and sorted for dependable use in its next service life. Millwood’s national network ensures consistent quality and reliable supply at a lower cost.

-

Lower Cost

-

Sustainable Choice

-

Inspected for Quality

Combo stringer pallets blend new and recycled materials for strength and savings. They provide more durability than used pallets and lower cost than all-new builds. This hybrid option offers dependable performance while supporting sustainability goals.

-

Balanced Value

-

Inspected for Quality

-

Sustainability Advantage

-

Flexible Supply

We want our customers to find the best product solutions for your process. Listed below are the common sizes for pallets. If you don’t see a size that would work for you, we would love to help you figure out a custom pallet, custom designed for you.

48×40 | 48×42 | 48×44 |

|---|---|---|

48×45 | 48×48 | 42×48 |

36×36 | 32×30 | 30×30 |

Custom Requirements? No Problem.

- Under-engineering that can result in pallet failure and product damage

- Over-engineering that drives up unnecessary costs and excess freight weight

- Instead, we deliver a just-right solution—balanced for strength, cost, and performance

Why Choose Millwood as Your Pallet Supplier?

- Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

- Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and design services enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

- Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Stringer Pallets

We will work to understand the problems you are having and as a team to provide solutions.

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify, and optimize designs to reduce product damage, minimize waste, and improve supply chain efficiency.

Pallet Recycling

Millwood offers complete pallet recycling programs to retrieve, inspect, recover, and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

More than just a pallet supplier

We’ve hand-picked these products to create a comprehensive solution that complements your pallet needs.

Frequently Asked Questions

What is a stringer pallet?

A stringer pallet uses runners (stringers) to support deck boards, making it the most common and cost-effective pallet design in the U.S.

Stringer pallets are built with two or three parallel stringers that support the top and bottom deck boards. This construction allows forklifts and pallet jacks to lift and move loads efficiently. More than 80% of pallets used in North America are stringer pallets, largely in the standard 48×40 size. Their wide adoption makes them highly compatible across industries, supply chains and shipping environments. Millwood engineers both new and recycled stringer pallets, ensuring every design meets the exact strength, handling and compliance requirements of your application.

Can stringer pallets be reused or recycled?

Yes. With inspection and repair, stringer pallets can be reused multiple times, and at end-of-life they can be fully recycled.

Many stringer pallets are built for reuse in closed-loop systems. Hardwood builds with reinforced fasteners extend service life, and Millwood provides repair and recovery programs to ensure safety before reuse. Once pallets reach the end of their lifecycle, they can be dismantled for parts or recycled into mulch, animal bedding and biofuel. Our pallet recycling program helps reduce landfill waste and supports corporate sustainability initiatives, making stringer pallets an environmentally responsible choice.

How do stringer pallets compare to block pallets?

Stringer pallets use runners for support, while block pallets use blocks for added strength and full four-way entry.

The primary difference between the two designs is in construction. Stringer pallets rely on stringers (runners) that allow two-way entry by pallet jack and four-way forklift entry with notched designs. Block pallets, by contrast, use blocks at each corner and along the edges, allowing forklifts to access from all four sides. While block pallets may support heavier or repeated loads, stringer pallets remain the most cost-effective, lightweight option for high-volume supply chains. Millwood helps customers decide between stringer and block pallets using PDS modeling and Millwood Lab testing.

What sizes do stringer pallets come in?

The standard size is 48×40, but stringer pallets can be custom-built in a variety of dimensions.

The 48×40 pallet is the industry standard in North America, but Millwood engineers stringer pallets in many other configurations, including 42×42, 48×45 and 40×48. The best size depends on your product’s footprint, stacking method and supply chain requirements. Using the Pallet Design System (PDS), Millwood customizes pallet builds to deliver the optimal balance of load capacity, handling efficiency and freight weight reduction. Our ISTA-certified Millwood Lab verifies every design to ensure pallets perform under real-world shipping conditions.

Which industries use stringer pallets?

Stringer pallets are used in food & beverage, automotive, pharmaceuticals, agriculture and building materials industries worldwide.

Because they are affordable, durable and widely compatible, stringer pallets serve nearly every sector of manufacturing and distribution. Food and beverage suppliers often need heat-treated, ISPM-15 compliant stringer pallets for exports. Automotive and aerospace manufacturers rely on reinforced hardwood pallets for heavy components. Agricultural producers use them to move bulk goods, while pharmaceuticals prefer precise, clean builds for compliance. Millwood designs pallets to fit each sector’s specific requirements, ensuring product safety and handling efficiency across supply chains.