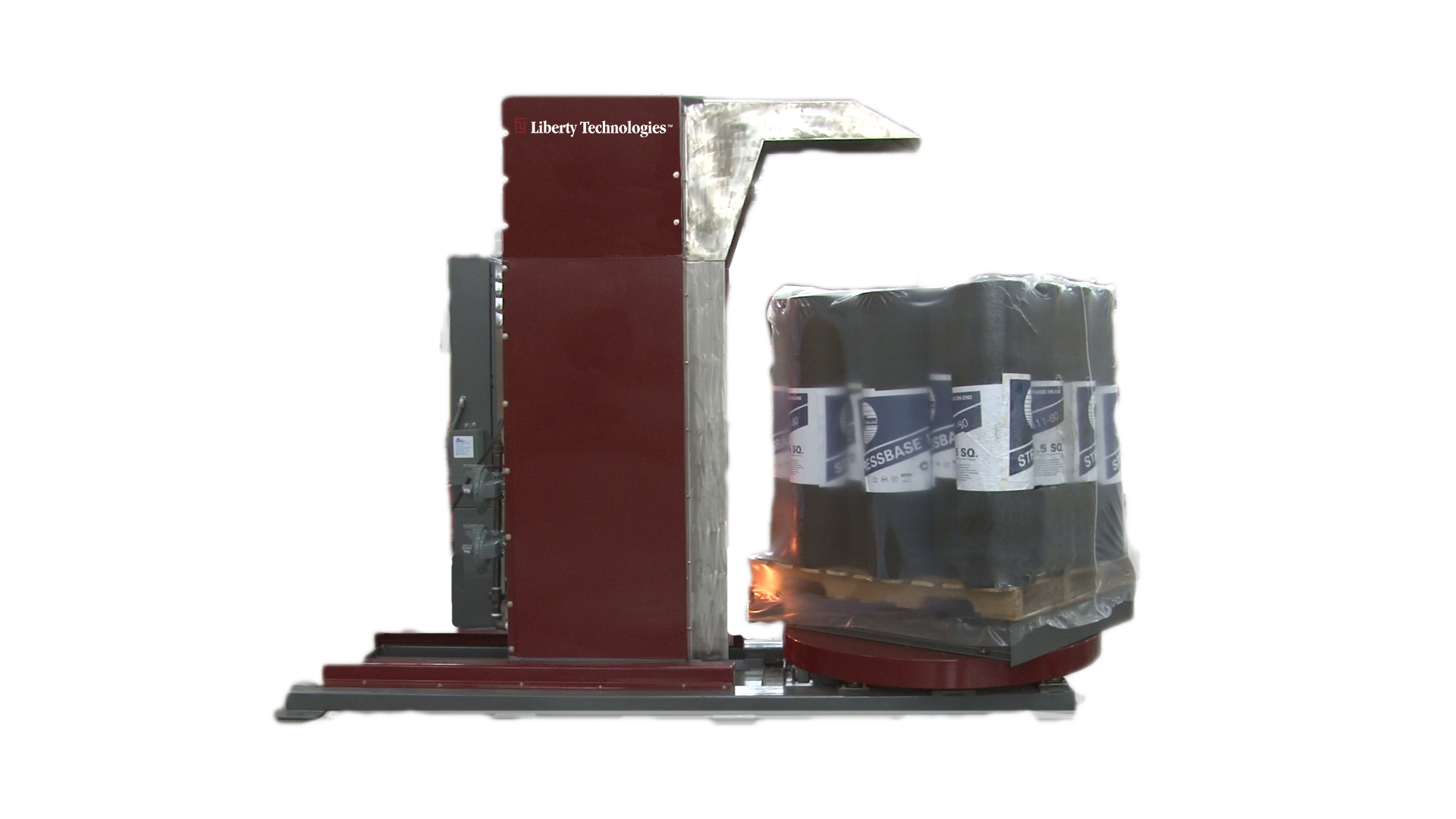

Shrink Wrapping Machines

Request a Quote

Thank you for reaching out about a quote from our team. Please complete the form below and one of our team members will be in touch with you. If you are currently or planning to use this product for multiple applications, please complete the form with the information from your largest load by total dimension. (LxWxH)

Shrink Wrapping Machines for Superior Load Protection

Protect your products and pallets with reliable shrink wrapping machines. Our shrink wrap system provides a tight, waterproof seal around loads of all shapes and sizes, ensuring safety during shipment or outdoor storage.

Versatile Shrink Wrap Equipment

Our shrink wrap equipment adapts to both light and heavy loads, offering five-sided coverage, UV protection and a tamper-evident seal. Shrink wrap material can be clear, opaque, colored or branded to promote your company’s image.

Types of Shrink Wrap Systems

Choose from single turntable, dual turntable or dual column shrink wrap systems for different process rates and load sizes. Automated and manual systems maximize efficiency, providing consistent protection with minimal labor.

Custom Requirements? No Problem.

- Under-engineering that can result in pallet failure and product damage

- Over-engineering that drives up unnecessary costs and excess freight weight

- Instead, we deliver a just-right solution—balanced for strength, cost, and performance

Why Choose Millwood as Your Solution Provider?

- Customer Centric Approach: We collaborate closely with customers, providing personal service and responsive support to meet your unique needs.

- Industry Expertise Since 1985: With over four decades of experience, Millwood understands the complexities of pallet design and supply chain logistics.

- Innovative Design & Testing: Our in house ISTA certified lab and Pallet Design System (PDS) enable tailored, optimized pallet solutions.

- Manufacturing Experts: From sawmilling, resawing, assembly, heat treating and mold prevention, we have the experience and knowledge to serve you.

- Sustainability Commitment: We are committed to efficiency without compromising our environment.

Proven Solutions that Complement our Packaging Systems

We will work to understand the problems you are having and as a team to provide solutions.

Millwood Lab

Our ISTA-certified test lab gives customers confidence that their wood pallets and packaging solutions will perform in real-world conditions. By simulating shipping and handling environments, we test, verify, and optimize designs to reduce product damage, minimize waste, and improve supply chain efficiency.

System Maintenance

Millwood offers complete pallet recycling programs to retrieve, inspect, recover, and remanufacture or repair pallets. Our recycled pallet and recovery programs include green recycling processes that complement corporate sustainability initiatives.

PROVIDING SUPPLY CHAIN SOLUTIONS

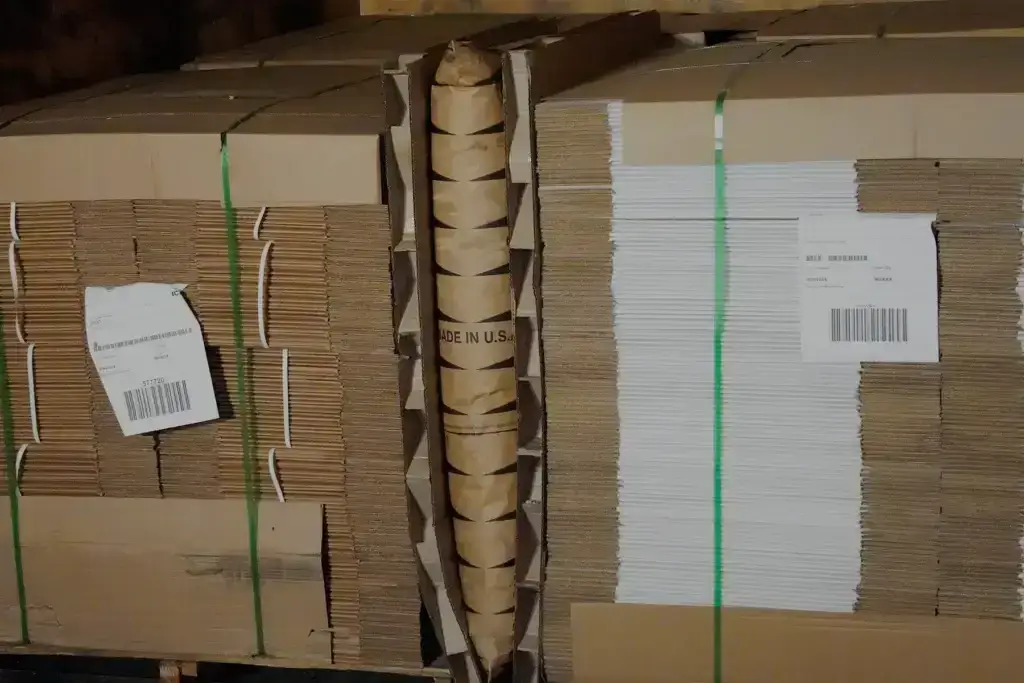

We’ve hand-picked these products to create a comprehensive solution that complements your packaging needs.

Heavy-duty bags designed for oversized or irregular loads. Shrinks to form a tight seal for weather resistance and long-haul stability.

Rely on the strength and durability of our wood pallets that are engineered to your specific packaging applications.

Corrugated panels that prevent lateral shifting, reduce air bag void space and add pallet underhang support. Lightweight yet strong and fully recyclable.

Frequently Asked Questions

What is a shrink wrapping machine?

A shrink wrapping machine uses heat and shrink film to tightly seal and protect products.

Shrink wrapping machines apply a layer of shrink film around items, then use heat to contract the film for a secure fit. This process protects products from dust, dirt and moisture while creating a tamper-evident seal. Industrial shrink wrap machines are commonly used in food, beverage, manufacturing and retail supply chains. By automating this process, shrink wrapping equipment ensures consistent packaging quality, reduces manual labor and supports efficiency in high-volume operations.

How do shrink wrapping machines support supply chain efficiency?

Shrink wrapping machines reduce damage, cut labor and improve logistics through consistent packaging.

Shrink wrap systems allow businesses to pack items more securely, reducing the risk of breakage during transit. Because the machines automate sealing and shrinking, they require less manual handling, lowering injury risk and labor costs. Consistent shrink packaging also maximizes cube-out efficiency in storage and shipping, reducing freight costs. Many industrial shrink wrapping machines can be integrated with conveyors and other packaging equipment, creating a seamless packaging flow that improves overall supply chain efficiency.

What are the benefits of using shrink wrap equipment?

Shrink wrapping machines improve product protection, packaging efficiency and supply chain performance.

Industrial shrink wrap equipment provides multiple benefits: it shields products from environmental damage, reduces shipping space by keeping items tightly packed and creates a professional retail-ready appearance. Automated shrink wrap systems further cut labor costs, minimize errors and enhance throughput on packaging lines. Many businesses also value shrink wrapping for its sustainability benefits, as it reduces excess packaging while maintaining durability. These advantages make shrink wrap packaging solutions ideal for companies aiming to streamline operations and reduce total costs.

What industries use shrink wrapping machines?

Shrink wrapping machines are used across food, beverage, retail, logistics and manufacturing sectors.

Shrink wrapping is a versatile packaging method adopted by industries that require durability and product integrity. Food and beverage companies rely on shrink wrap equipment to maintain freshness and prevent contamination. Retailers use shrink packaging solutions to prepare products for shelves while reducing tampering risks. Manufacturers and logistics companies benefit from shrink wrapping machines that securely bundle products for transport. This wide application makes shrink wrap systems a critical investment for businesses looking to improve packaging protection and efficiency.

How do I choose the right shrink wrapping machine?

Choosing the right shrink wrapping machine depends on your product type, volume and packaging goals.

When selecting shrink wrap equipment, businesses should first evaluate the size and type of products they need to package, as well as their production volume. Manual or semi-automatic machines may be suitable for smaller operations, while automated shrink wrapping systems are ideal for high-volume packaging lines. Consider key factors such as shrink film compatibility, machine durability, speed and maintenance requirements. Partnering with a provider who can test and customize shrink packaging solutions ensures that your investment aligns with long-term efficiency and growth.